Spatial pre-embedded type three-dimensional stress monitoring system and method for underground coal and rock mass

A three-dimensional stress and monitoring system technology, applied in the field of coal and rock mass safety, can solve problems such as difficulty in mastering, inability to accurately judge the direction and size of the incoming pressure of coal and rock mass, and inaccurate monitoring data, so as to improve safety. , the effect of high measurement accuracy and reliability, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

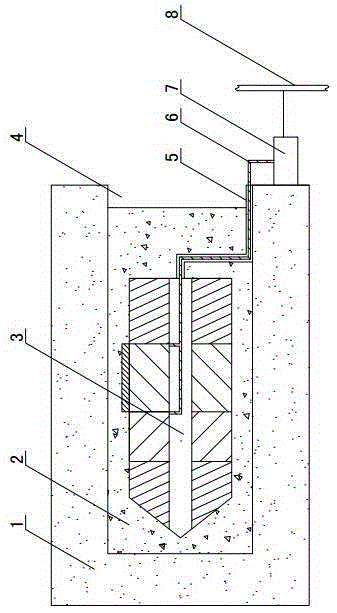

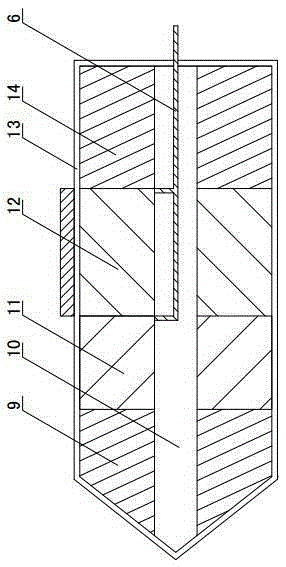

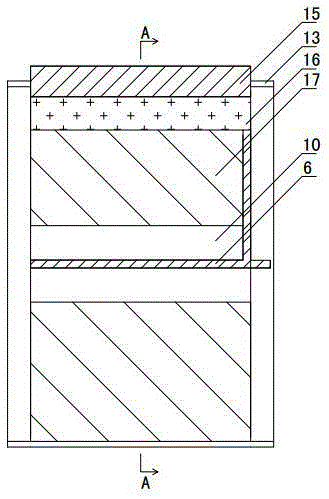

[0040] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0041] Such as figure 1 As shown, the underground coal and rock mass space pre-buried three-dimensional stress monitoring system includes an induction output device 3 fixed in the coal and rock mass 1 . An installation borehole 4 is provided on the coal rock mass 1, and after the induction output device 3 is installed in the installation borehole 4, the induction output device 3 is fixed by pouring concrete filling 2 into the installation borehole 4. Before pouring concrete filling 2 into the installation borehole 4, the signal line protection tube 5 is pre-embedded first, which is used to lead out the signal line 6 in the induction output device 3. The signal line 6 adopts a multi-core signal line, which can independently output different signals simultaneously electric signal. After the signal line 6 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com