Cluster magnetorheological polishing pad performance test device and method

A technology of magnetorheological polishing and testing equipment, which is applied in the direction of testing material hardness, grinding/polishing equipment, grinding machine parts, etc., and can solve problems such as inability to compare and analyze normal pressure and shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

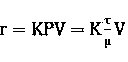

Image

Examples

Embodiment 1

[0046] Example 1: Using a unidirectional piezoelectric sensor to measure the positive pressure of the cluster magnetorheological polishing pad on the workpiece

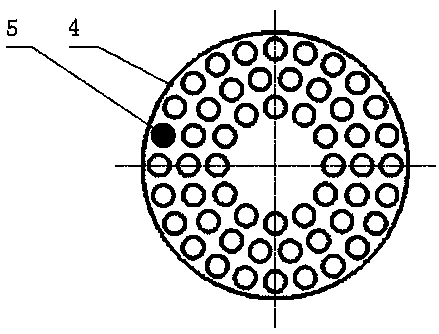

[0047] Step 1: Embedding clustered cylindrical permanent magnets 5 with an end surface magnetic field strength of 2000Gs on the antimagnetic polishing disc 4 to form a cluster distributed high-gradient magnetic field on the polishing disc surface;

[0048] Step 2: According to carbonyl iron powder (CIPs) 30-40%wt, abrasive grains (diamond powder, silicon carbide, aluminum oxide, cerium oxide, silicon dioxide, etc.) 2-10%wt, deionized water 50-70%wt , Glycerin 8%wt, dispersant 8%wt ratio configuration magnetorheological polishing working fluid, the prepared magnetorheological polishing working fluid is injected into the storage tank, and the magnetorheological polishing working fluid is circulated and stirred by an agitator;

[0049] Step 3: Install the non-magnetic fine duralumin stylus 3 on the miniature piezoelectri...

Embodiment 2

[0053] Example 2: Using a unidirectional piezoelectric sensor to measure the shear force of a cluster magnetorheological polishing pad on a workpiece

[0054] Such as image 3 As shown, the difference between measuring shear force and measuring positive pressure is that the installation position of the piezoelectric sensor is different. The force sensing surface of the piezoelectric sensor is perpendicular to the direction of the shear force. When measuring the shear force along the X-axis, the pressure The force-sensing surface of the electric sensor is perpendicular to the X-axis direction; when measuring the shear force along the Y-axis direction, the force-sensing surface of the piezoelectric sensor is perpendicular to the Y-axis direction, and other steps are the same as in Embodiment 1.

Embodiment 3

[0055] Embodiment 3: Simultaneously measure the normal pressure and shear force of the clustered magnetorheological polishing pads on the workpiece by using bidirectional / tridirectional piezoelectric sensors.

[0056] Such as Figure 4 As shown, the three-way force piezoelectric sensor can be used to simultaneously measure the normal pressure of the cluster magnetorheological polishing pad on the workpiece at a certain point and the components of the shear force along the X and Y directions. The installation method of the sensor is the same as that of Embodiment 1. The signal of Luli can be converted into digital signal by multi-channel A / D conversion card and sent to the computer.

[0057] It can be seen from the above examples that the cluster magnetorheological polishing pad performance test (hardness, elasticity) method of the present invention uses a stylus to measure the local point polishing force, and uses a CNC system to control the movement of the stylus and the poli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com