Method for representing recovery characteristics of Fe-Mn-Si-based memory alloy by in-situ X-ray diffraction

A technology of fe-mn-si and memory alloy, which is applied in the direction of material analysis using radiation diffraction and the preparation of test samples, can solve problems such as difficult macroscopic angles, difficult dynamic analysis, and complicated sample preparation, and achieves Effect of reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Taking the composition as an example of Fe-15Mn-6Si-9Cr-4Ni-0.5V-0.16N-based memory alloy, that is, the Fe-Mn-Si-based memory alloy contains 15% by weight of Mn, 6% of Si, 9% Cr, 4% Ni, 0.5% V, 0.16% N, and the rest is Fe.

[0028] First preprocess:

[0029] (1) Melting and solution treatment: alloy ingots were smelted in a vacuum induction furnace, forged after homogenization treatment at 1200°C for 5 hours, and then hot-rolled at 1000°C into 20mm thick plates. The hot-rolled plate was subjected to solution treatment at 1150°C for 5 hours, so that the second phase forming elements could fully dissolve back, and a sample with uniform composition and structure was obtained.

[0030] (2) Wire cutting and aging treatment: The solution treated sample was subjected to wire cutting treatment to obtain a sample with a size of 8mm×50mm×0.7mm, and the wire cutting emulsified oil remaining on the surface of the sample was removed through chemical degreasing. The c...

Embodiment 2

[0039] Example 2: Take the Fe-15Mn-6Si-9Cr-4Ni-0.7V-0.2C-based memory alloy as an example, that is, the Fe-Mn-Si-based memory alloy contains 15% Mn by weight, 6% Si, 9% Cr, 4% Ni, 0.7% V, 0.2% C, and the rest is Fe.

[0040] First preprocess:

[0041] (1) Melting and solid solution treatment: the process is the same as that in the above-mentioned embodiment one.

[0042] (2) Wire cutting and aging treatment: The difference between this process and the above-mentioned embodiment 1 is only the final holding temperature and time, that is, finally let the sample be kept in a resistance furnace for 2 hours at 750°C, and after water quenching, the aging treatment is obtained. sample.

[0043] (3) surface treatment: the process is the same as that in the above-mentioned embodiment one.

[0044] (4) Stretching treatment: the process is the same as that in the above-mentioned embodiment one.

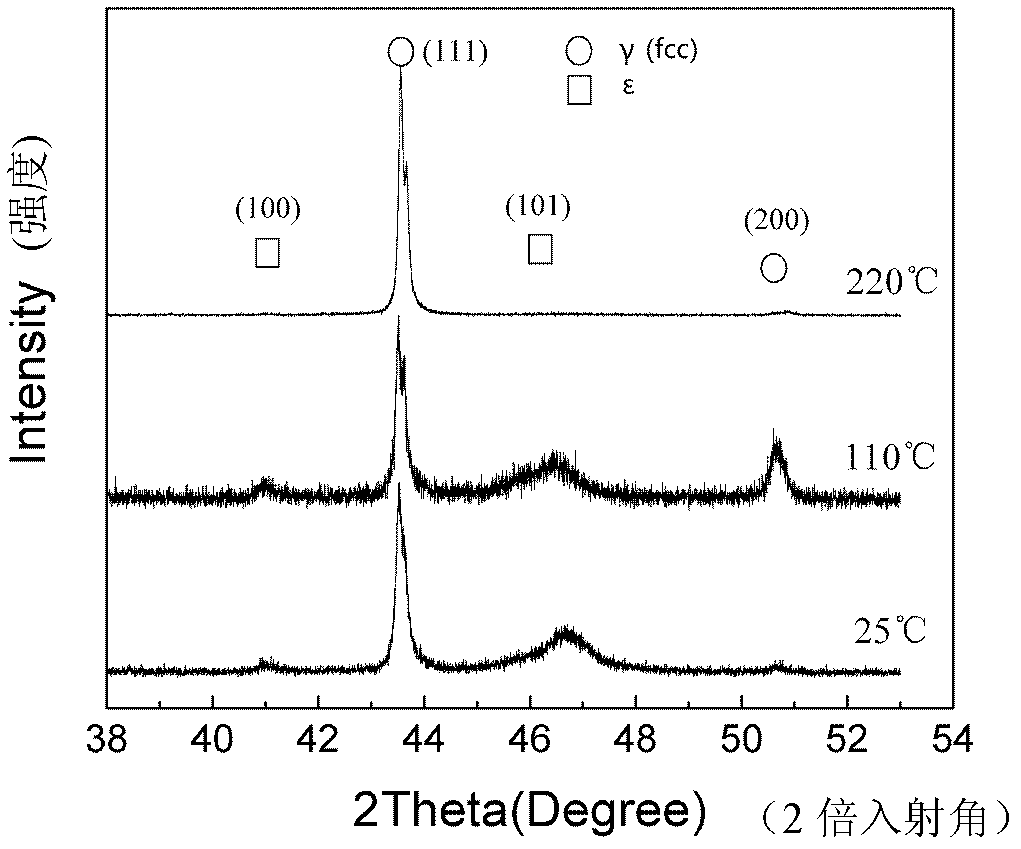

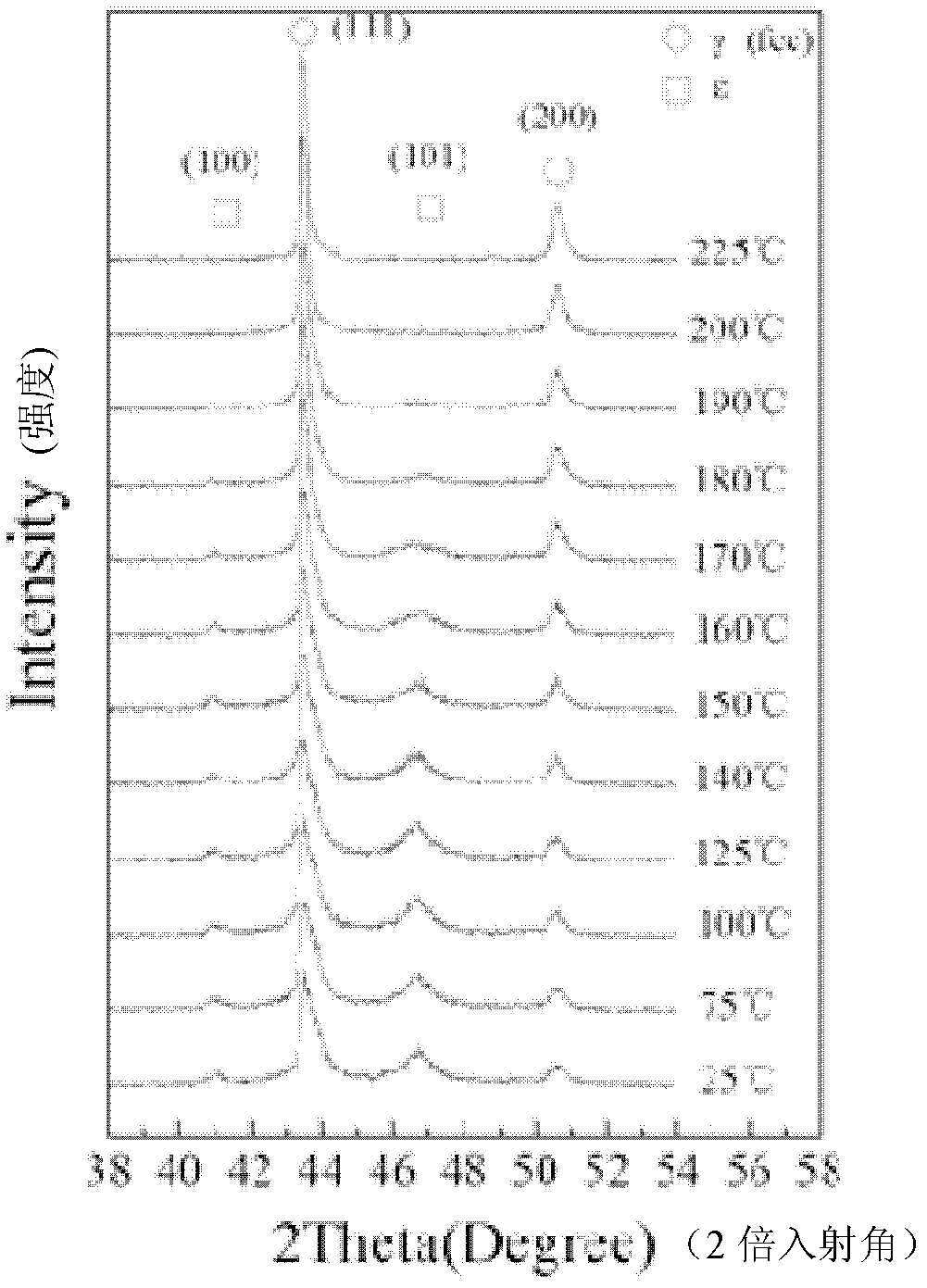

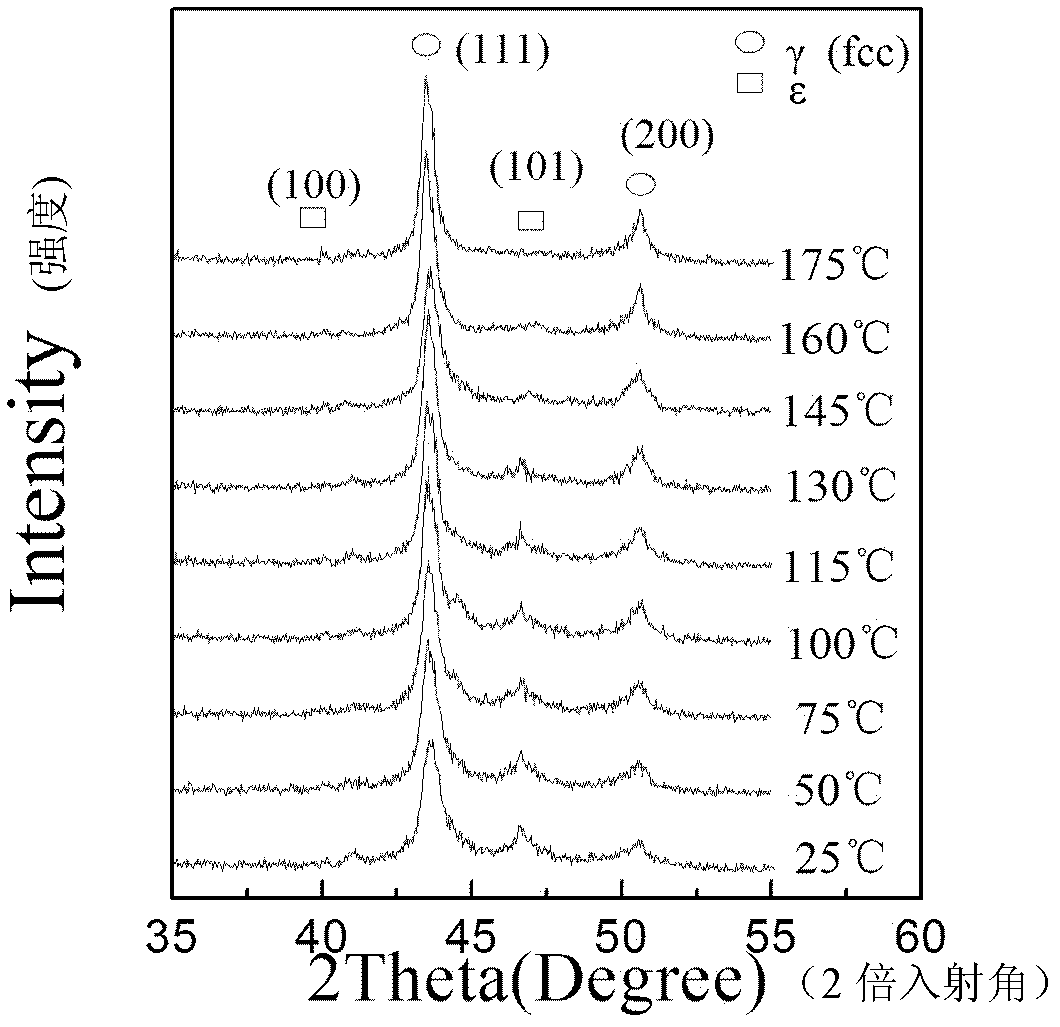

[0045] (5) 10% stretched Fe-17Mn-5Si-10Cr-5Ni-0.7V-0.2 by the TC-widerange high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com