Method and device for machining brittle transparent materials through lasers with multiple focal points distributed dynamically

A technology for laser processing and transparent materials, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, inability to realize closed graphics processing, low efficiency of material removal, etc., and achieve the goal of improving cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

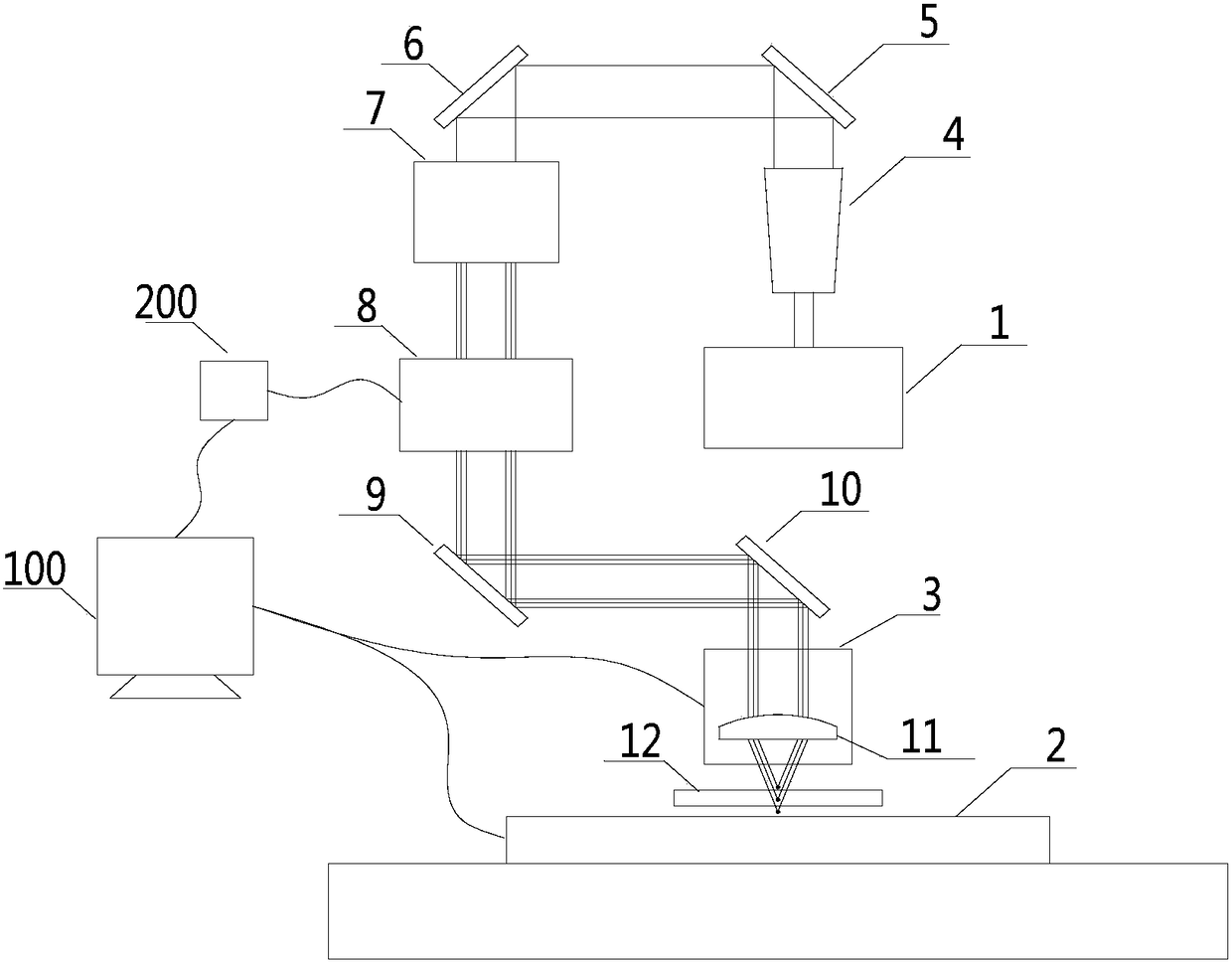

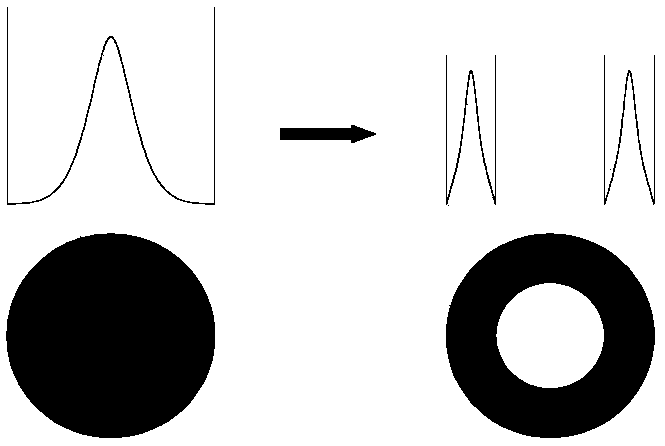

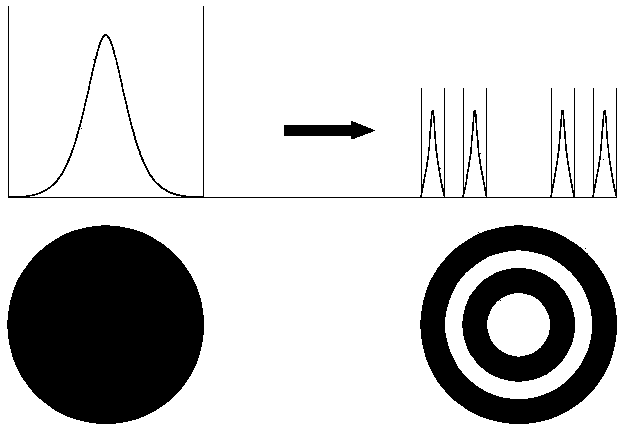

[0049] The invention is based on the laser stress induction cutting technology. The laser stress induction technology is to focus the laser on the inside of the material to form a blasting area inside and form a guiding direction for material fracture. The specific content is: the laser is usually focused into a small point, and these points are distributed inside the material. When the laser power density at the focal point is greater than the damage threshold of the material, a burst point will be formed inside the material. Each burst point is formed by a single laser pulse. With the displacement of the processed material relative to the laser focus, different shapes of line distribution can be formed, and the line distribution can be single-layer distribution, or multi-layer distribution can be real...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com