V-belt base glue and rope core bonding divider

A divider and bottom glue technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of strip blank distortion, affecting the bonding production efficiency, and group bottom glue cannot be positioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

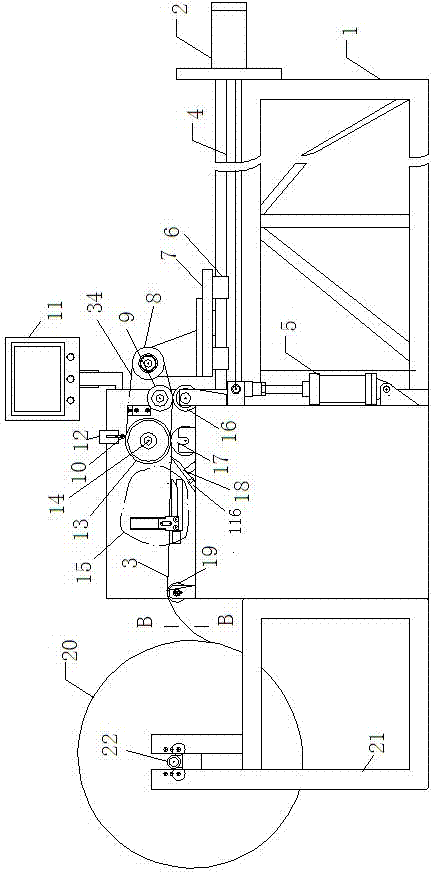

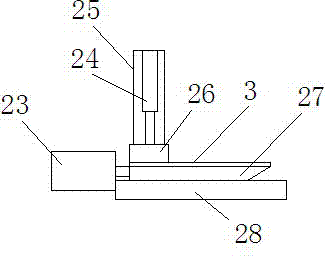

[0026] Depend on Figure 1-Figure 9 The shown V-belt bottom rubber and rope core bonding splitter includes a frame 1, which is sequentially provided with a bottom film support 21 for installing a bottom film 20, a rubber support roller 19 for clamping Primer roll 20 is primed and the primer feeding assembly 15, primer cutting assembly, driving roller 13 and driven roller 8 connected with the front and rear tensioning devices of the rope core are conveyed forward.

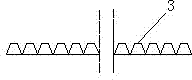

[0027] The bottom film support 21 is provided with a bottom film 20, and the bottom film support 21 is provided with a bottom film shaft 22 for installing the bottom film 20, and the rubber support roller 19 on the bottom film support 21 rear side is parallel to the bottom film shaft 22, and the bottom film support 21 is parallel to the bottom film shaft 22. The film 20 is coiled by rows of primers 3 , and the primers 3 drawn from the primer roll 20 enter the primer feeding assembly 15 from the rubber support roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com