Temperature sensor and method for producing same

A technology of temperature sensor and thin-film thermistor, which is applied in thermometers, resistors with negative temperature coefficient, resistance manufacturing, etc., can solve the problems of unclear thermal reliability and no heat resistance of nitride-based materials, and achieve unevenness Less, high bondability, less flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

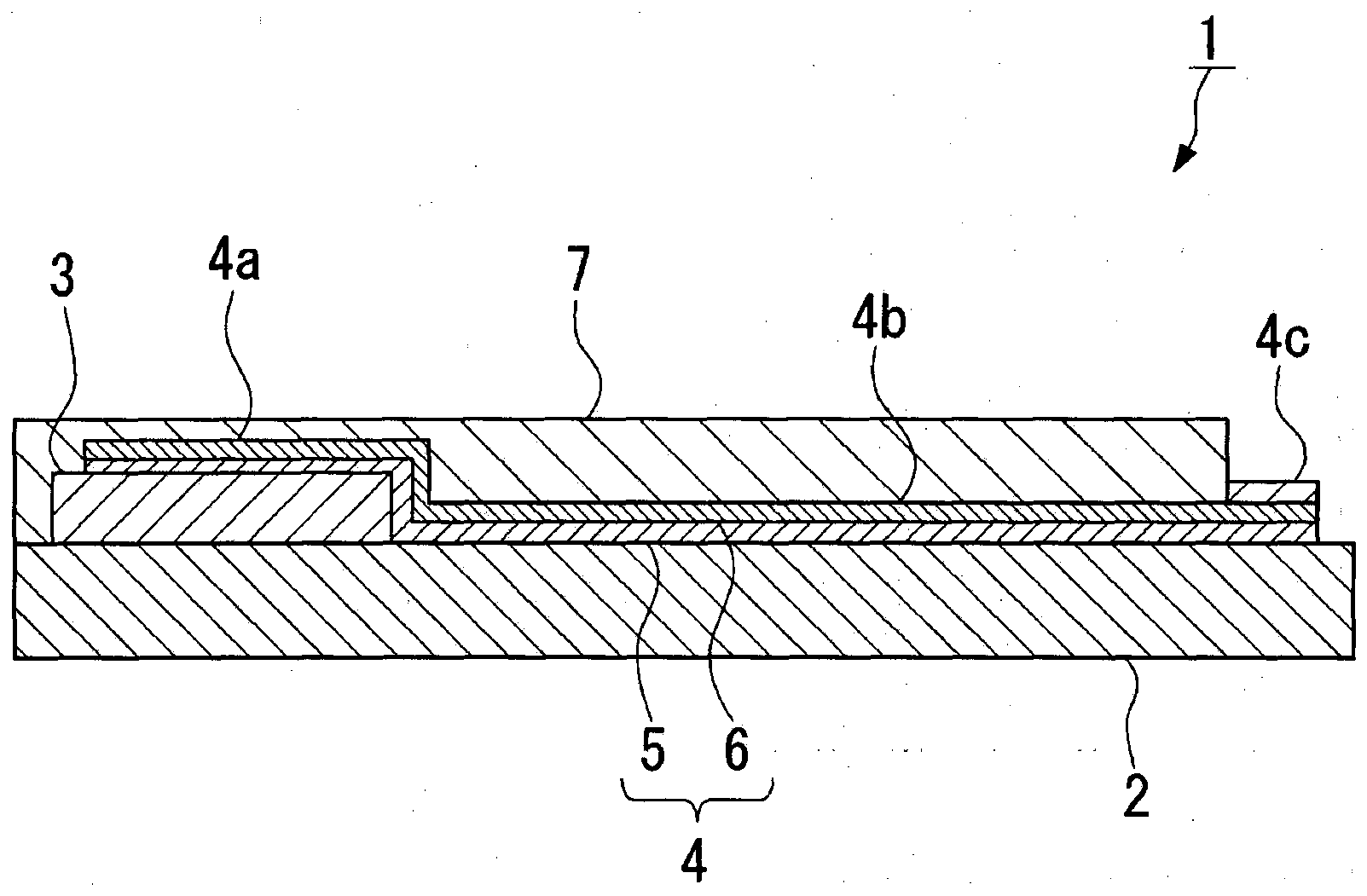

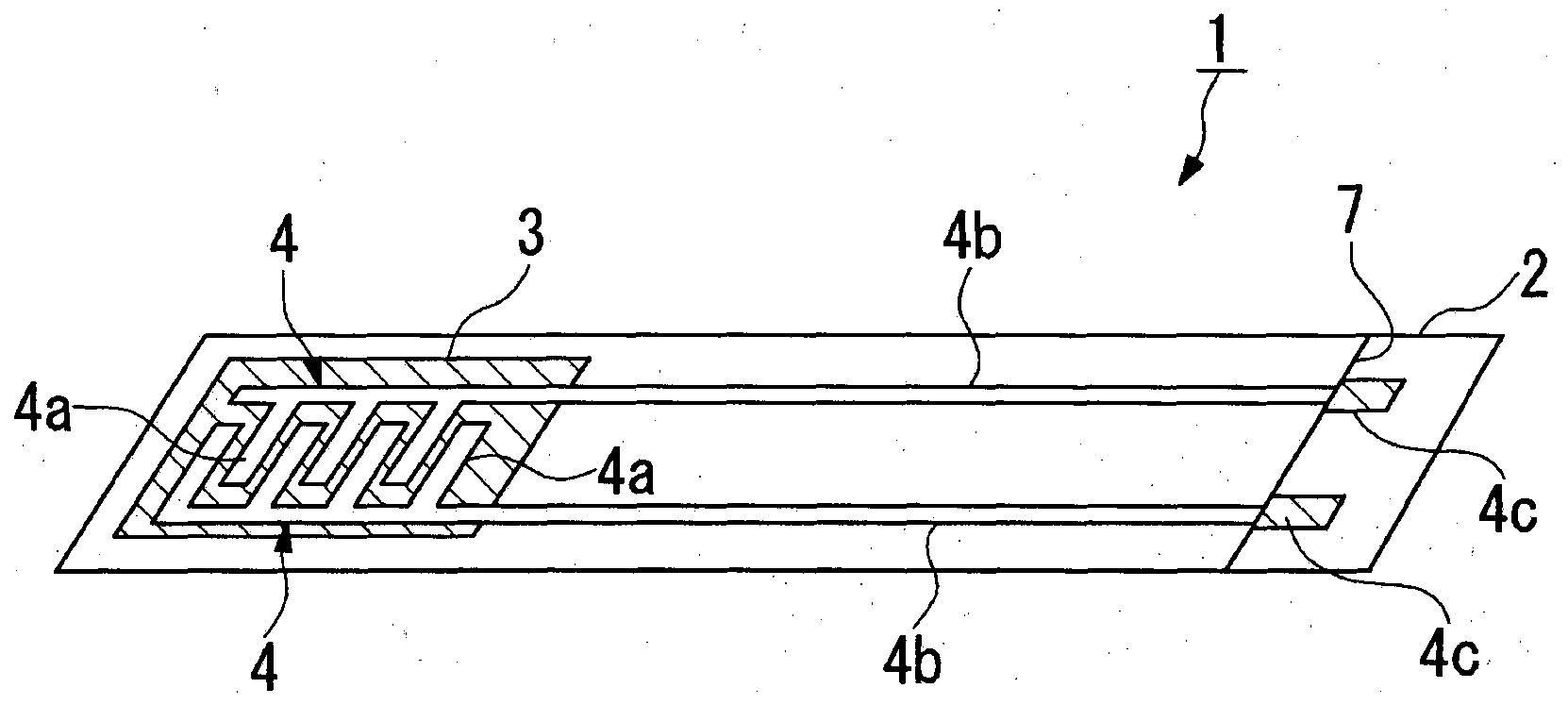

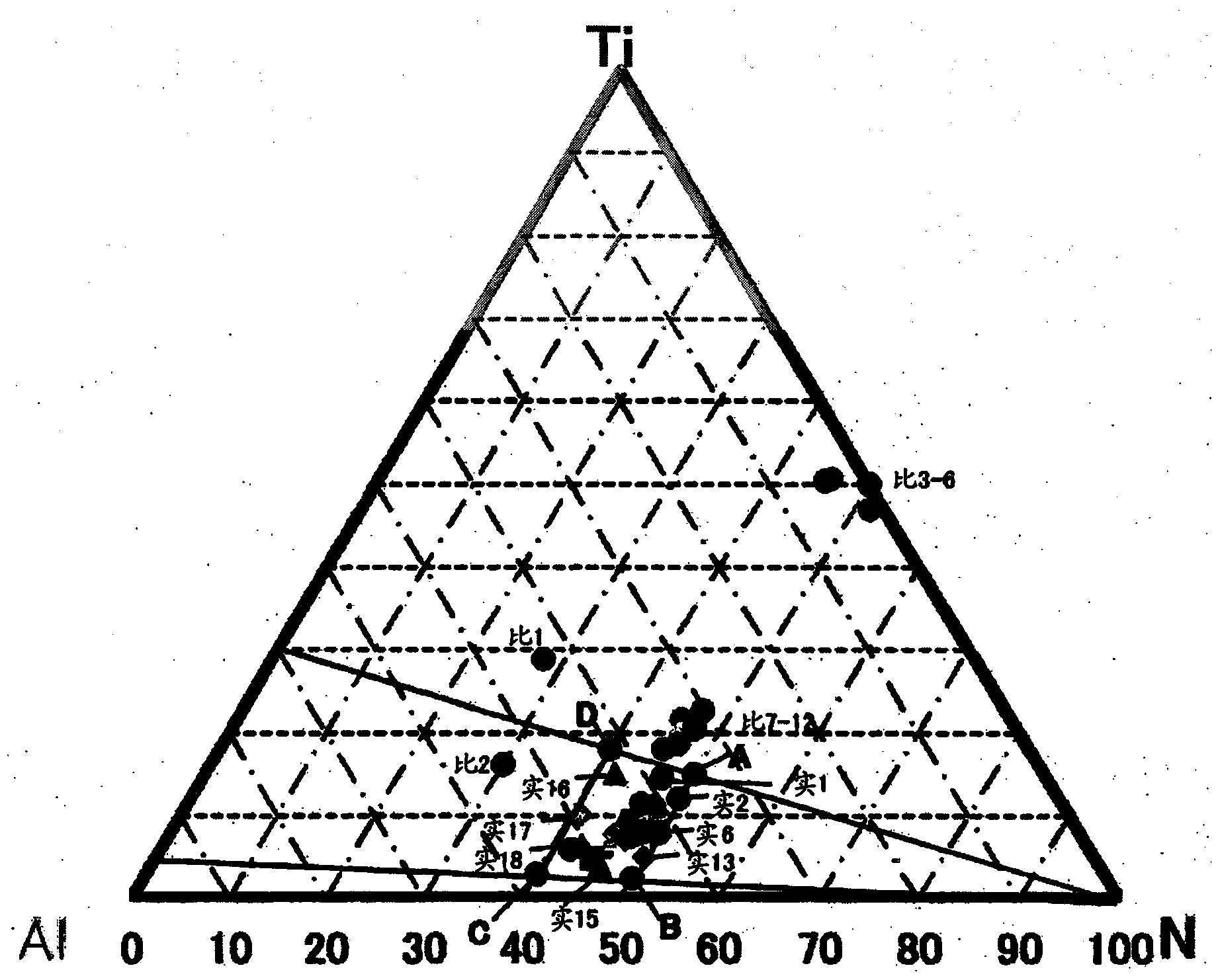

[0051] Next, for the temperature sensor and its manufacturing method involved in the present invention, refer to Figure 5 to Figure 13 The results of evaluation by the examples produced based on the above-mentioned embodiment will be specifically described.

[0052]

[0053] The resistance value change rate and the B constant change rate at the time of heat resistance test were investigated about the Example produced based on said embodiment. That is, the manufactured temperature sensor of the example was subjected to a heat resistance test at 125° C. for 1000 h in the air, and the electrical changes (resistance value change rate, B constant change rate) before and after the test were evaluated. In addition, for comparison, a temperature sensor using a bonding layer of Cr instead of TiN was also produced as a comparative example, and the above-mentioned evaluation was performed in the same manner.

[0054] As a result of this evaluation, it was found that the rate of chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com