Underground structure of municipal pipeline group spanning tunnel and construction method for underground structure

A technology for underground structures and pipeline groups, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as slow project progress, long construction period, tunnel impact, etc., and achieve fast construction progress, high work efficiency, Controlling the effect of tunnel heave deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

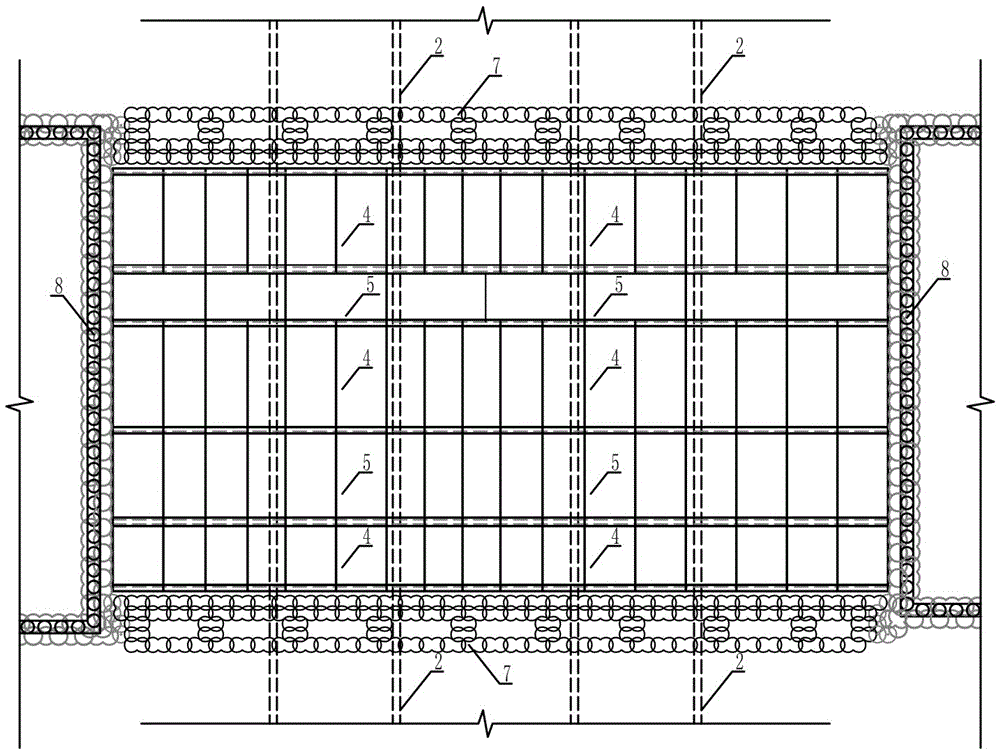

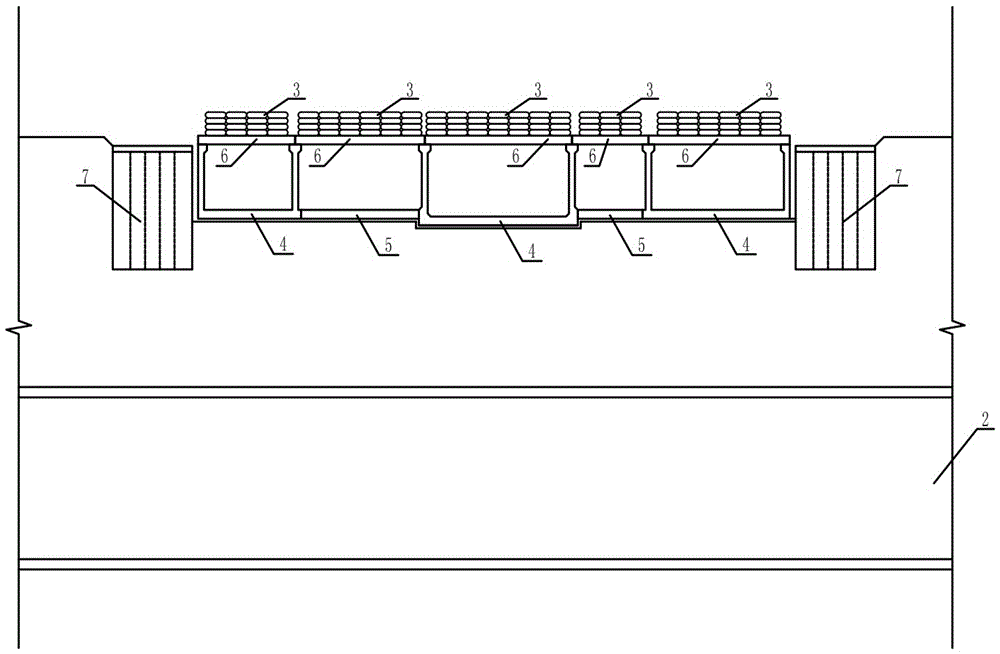

[0021] Directly below the foundation pit of the municipal pipeline project is the subway tunnel in operation, which is less than 6m away from the box structure that crosses the municipal pipeline of the subway tunnel. The specific construction steps are as follows:

[0022] (1) Foundation pit enclosure

[0023] See attached figure 1 According to the design requirements, the buried pipe area across the tunnel is determined, and the foundation pit enclosure is carried out according to the determined pipe buried area. On both sides of the north side are cast-in-place piles for the well, and three-axis mixing piles 8 are used for protection. The east and west sides of the foundation pit are protected by gravity dams 7. The underground structure of the municipal pipeline group spanning the subway tunnel 2 is a number of U-shaped grooves 4, A box-shaped structure formed by assembling the bottom plate 5 and the cover plate 6.

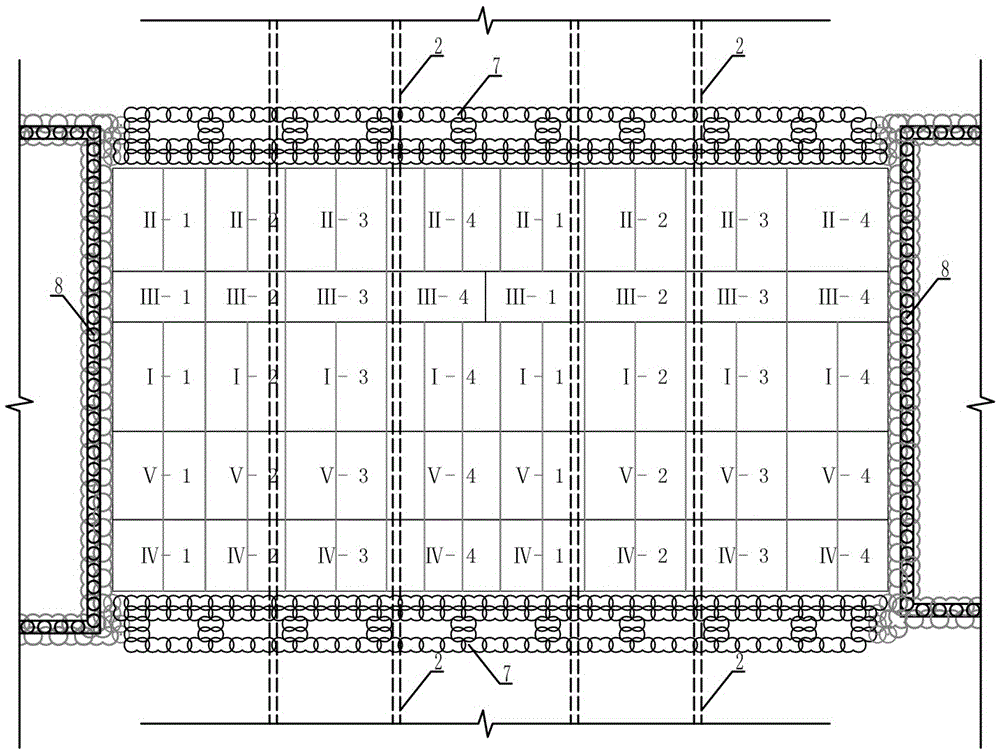

[0024] (2) Slot segment division

[0025] See attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com