Laminated inductor

An inductor and multilayer technology, applied in the field of multilayer inductors, can solve problems such as low volume resistivity, and achieve the effects of increasing L value, increasing strength, and increasing strength

Active Publication Date: 2013-02-13

TAIYO YUDEN KK

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the contrary, the volume resistivity of the material itself is much lower than that of conventional ferrite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0064] Hereinafter, the present invention will be described more specifically by way of examples. However, this invention is not limited to the aspect described in these Examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

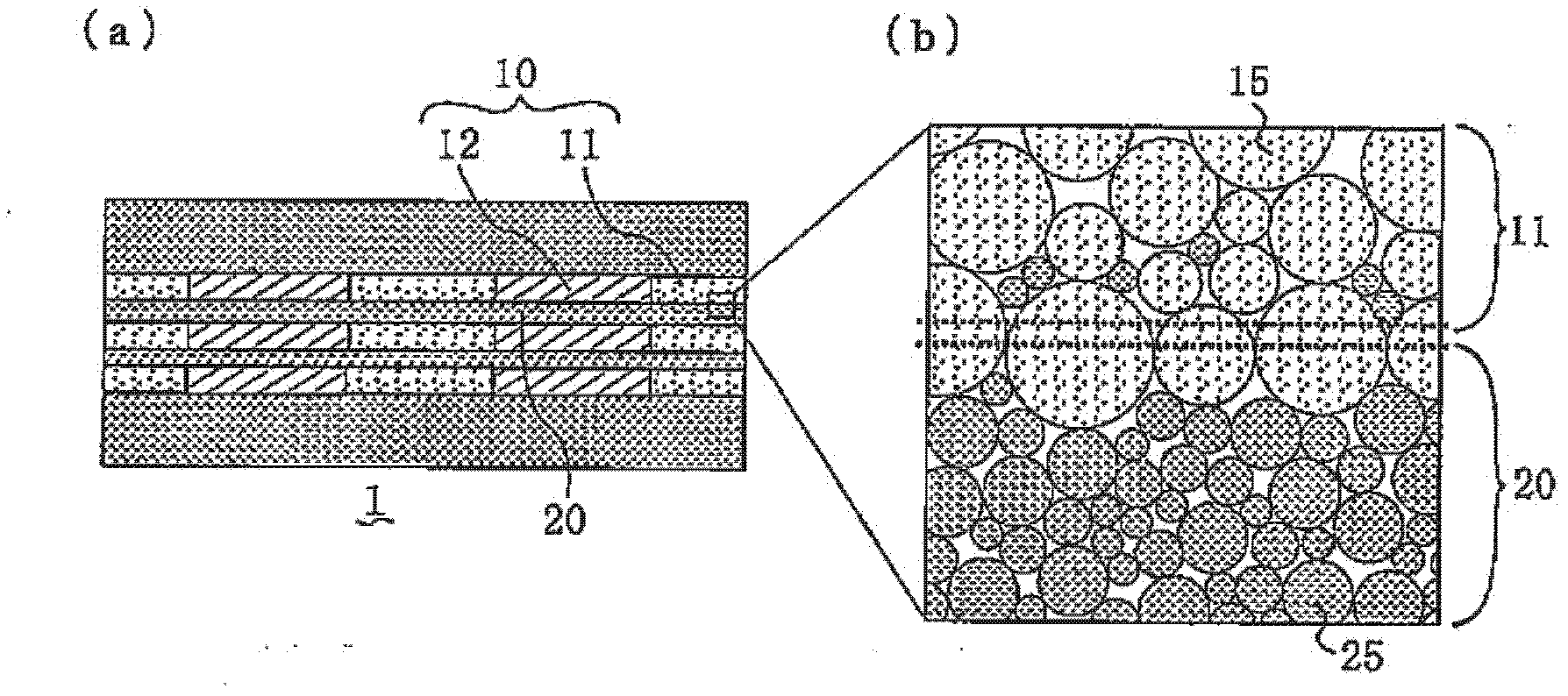

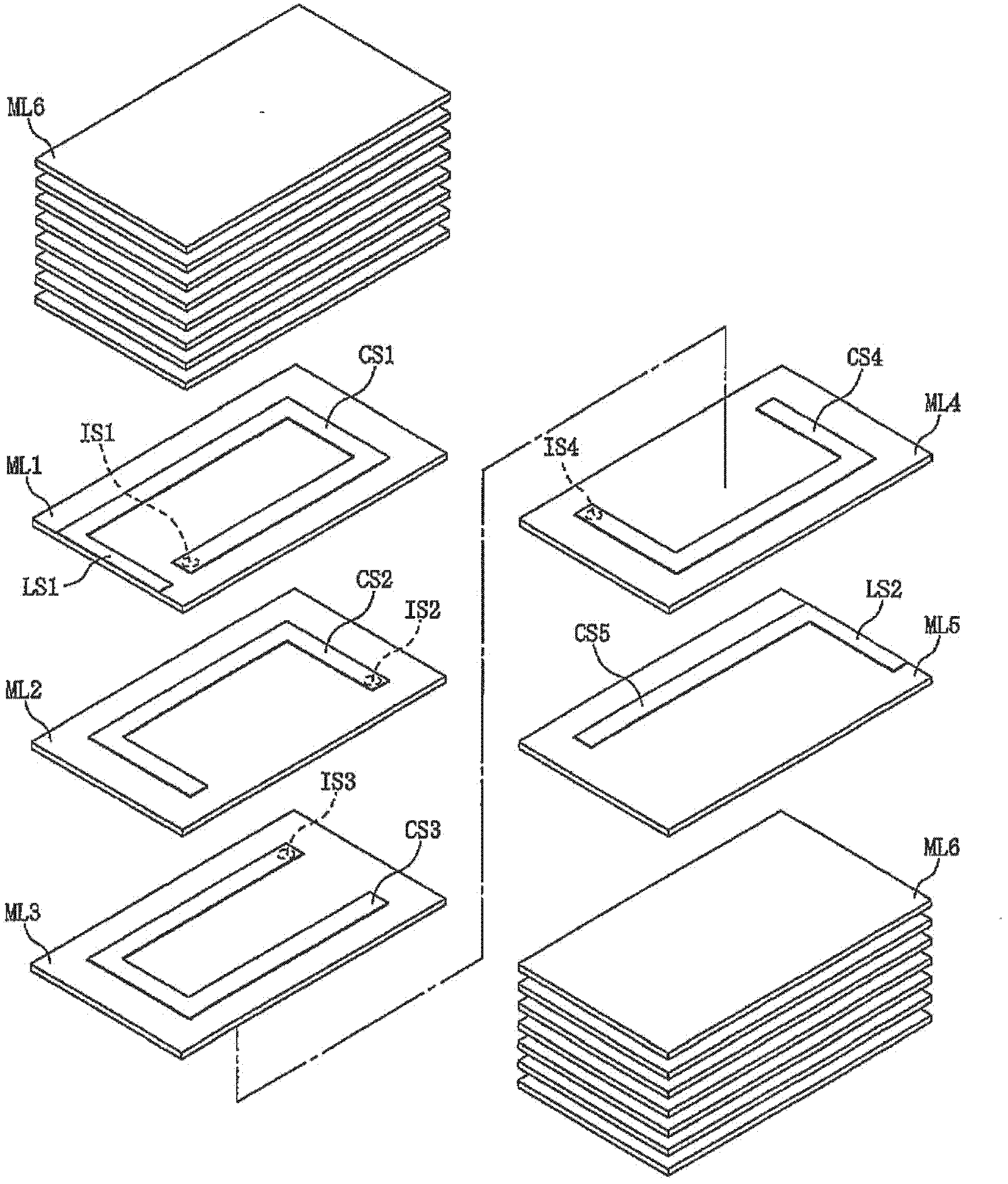

A laminated inductor having a laminate structure constituted by magnetic layers and internal conductive wire-forming layers, wherein the magnetic layer is formed by soft magnetic alloy grains, the internal conductive wire-forming layer has an internal conductive wire and a reverse pattern portion around it, and the reverse pattern portion is formed by soft magnetic alloy grains whose constituent elements are of the same types as those of, and whose average grain size is greater than that of, the soft magnetic alloy grains constituting the magnetic layer.

Description

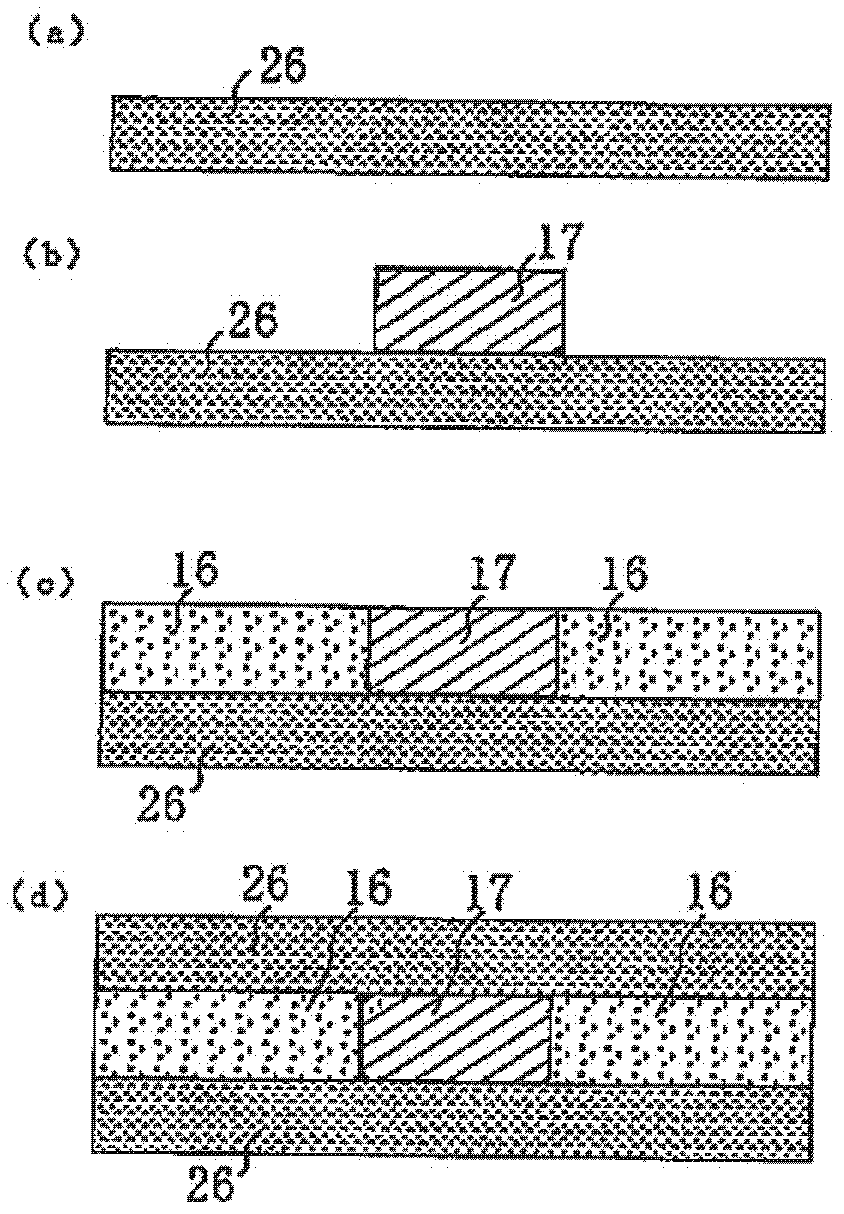

technical field [0001] The present invention relates to a multilayer inductor. Background technique [0002] Conventionally, as one of the methods of manufacturing multilayer inductors, there is known a method of printing internal conductor patterns on ceramic green sheets containing ferrite and the like, and laminating and firing these sheets. [0003] According to Patent Document 1, there is disclosed a method of manufacturing a laminated chip inductor obtained by crimping and firing an unfired ceramic laminate on which a conductor pattern is formed. In the manufacturing method of Patent Document 1, an auxiliary magnetic material layer is provided on a magnetic material green sheet at least around a conductor pattern, and the thickness of the auxiliary magnetic material layer after firing is greater than that of the conductor pattern after firing. [0004] In recent years, multilayer inductors have been required to increase the current (that is, to increase the value of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01F17/00H01F37/00

CPCH01F1/24H01F17/0013H01F27/255H01F27/28H01F1/33H01F2017/0066H01F17/00

Inventor 小林朋美松浦准新井隆幸八矢正大大竹健二

Owner TAIYO YUDEN KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com