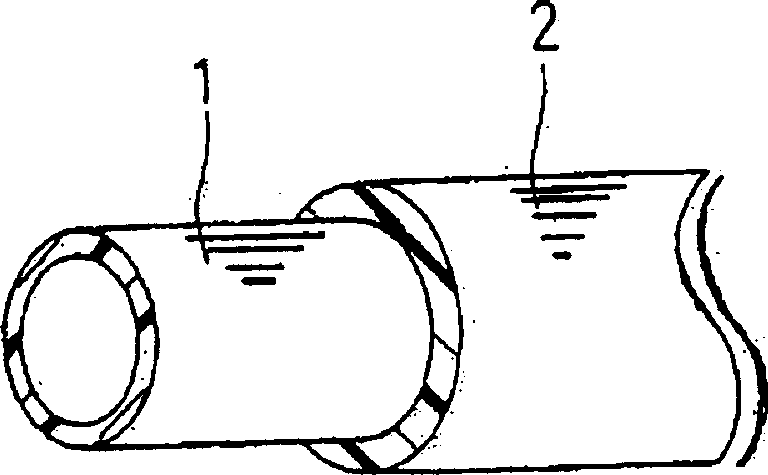

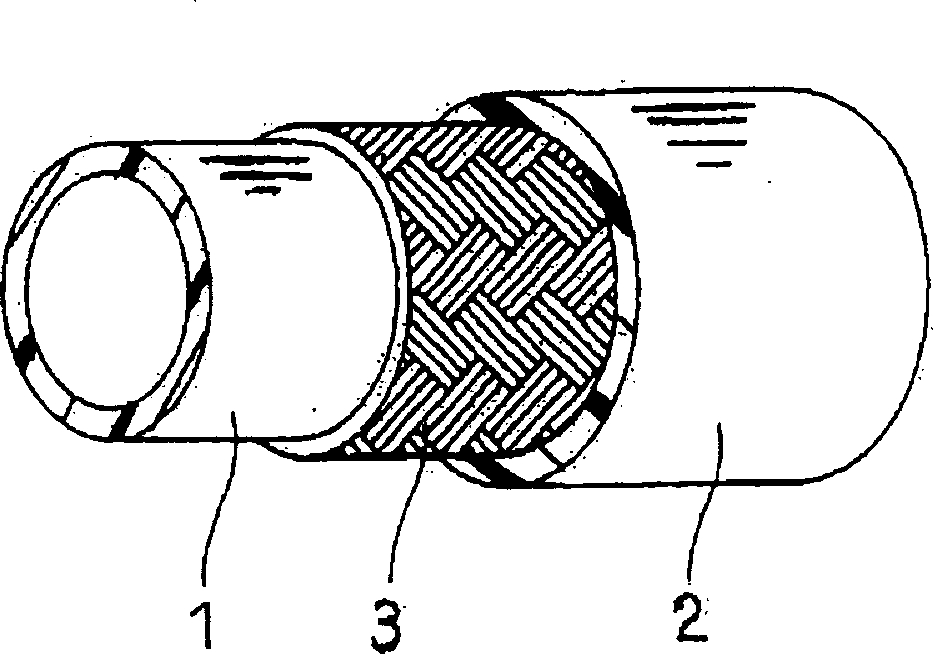

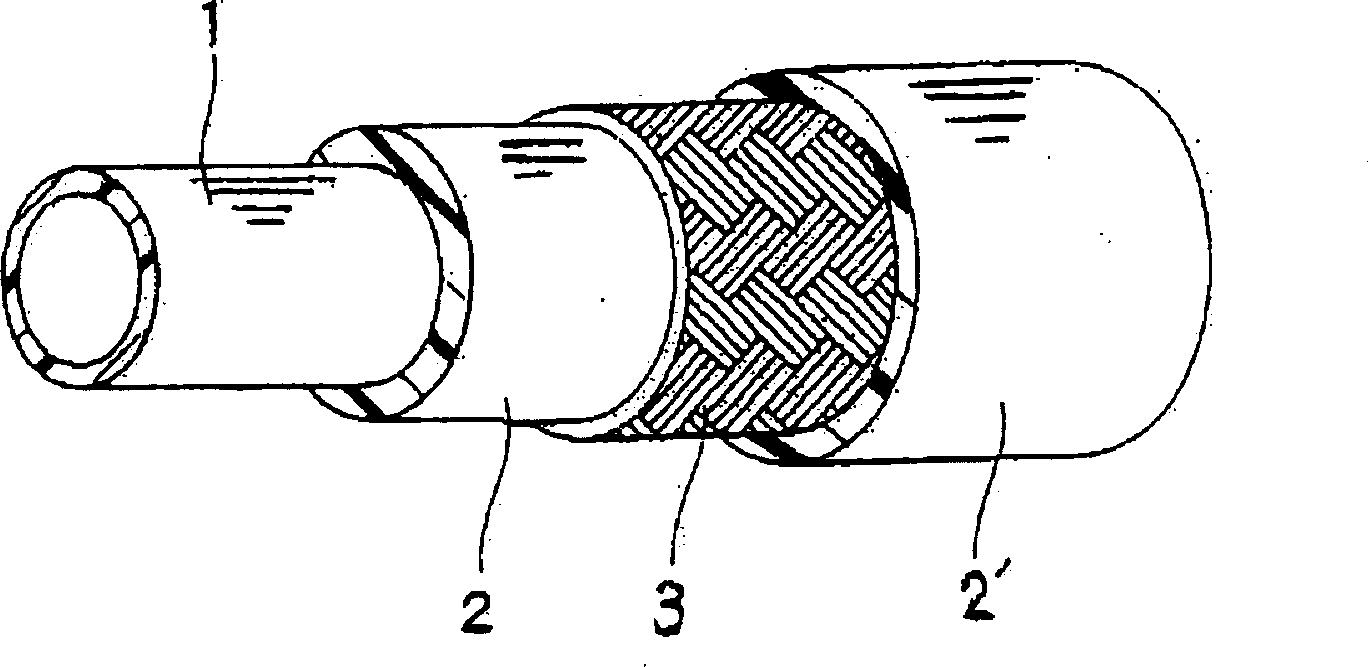

Heat-resistant hose

A hose and heat-resistant technology, which is applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of limited use, quality and reliability, and achieve excellent performance, good durability, and excellent heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0046] [Examples 1-5, Comparative Examples 1-5]

[0047] First prepare 100 parts of terpolymer of vinylidene fluoride, hexafluoropropylene and tetrafluoroethylene (Dayel G555, manufactured by Daikin Co.), 13 parts of carbon black SRF, 3 parts of MgO#150 and 6 parts of Ca(OH) 2 , This was kneaded using a 5L kneader to prepare a fluorine-containing rubber composition (for the inner layer).

[0048] Separately, the following materials were prepared, mixed in the ratios shown in Tables 1 to 2 below, and kneaded with a 5 L kneader to prepare an acrylic rubber composition (for outer layer). In addition, as the composition for the outer layer in Comparative Example 5, 100 parts of epichlorohydrin rubber (ECO), 75 parts of carbon black SRF, 5 parts of dioctyl phthalate (DOP) as a plasticizer, 1 Parts nickel dibutyldithiocarbamate (NBC) as anti-aging agent, 2 parts MgO#150, 3 parts hydrotalcite compound and 1 part 1,8-diazabicyclo[5.4.0]undecene - A rubber composition obtained by kne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com