Steel structure straw material plate composite floor deck member

A technology of steel structure and floor deck, applied in the field of steel structure components, can solve the problems of self-heavy filling material, low thermal insulation performance, poor construction environment, etc., and achieve the effects of convenient connection, reduced self-weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

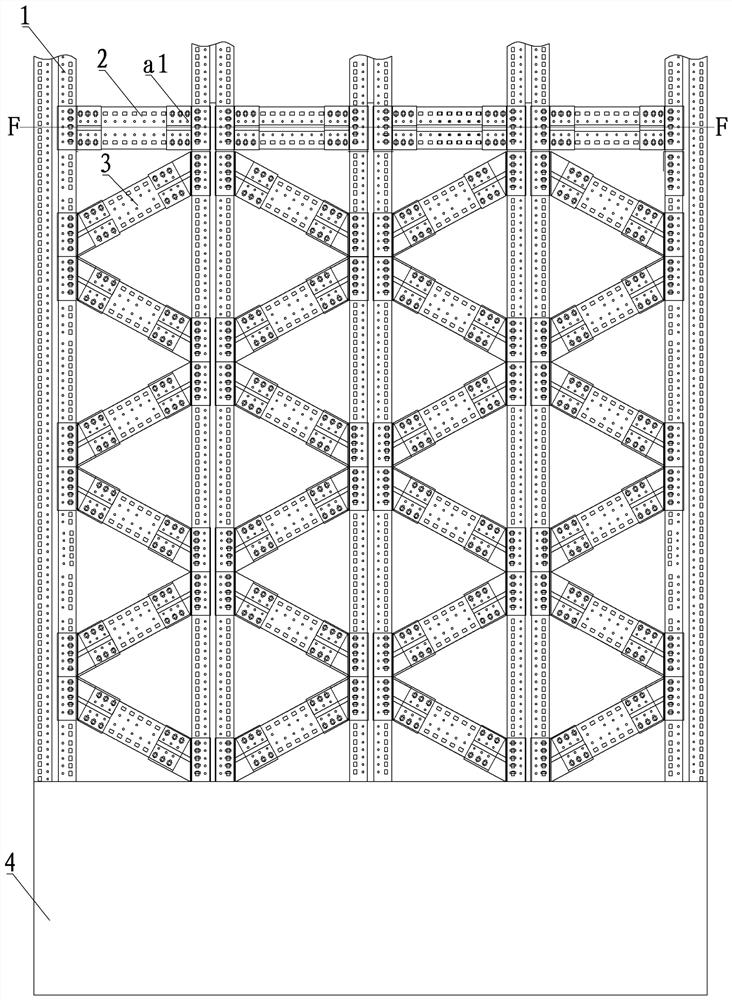

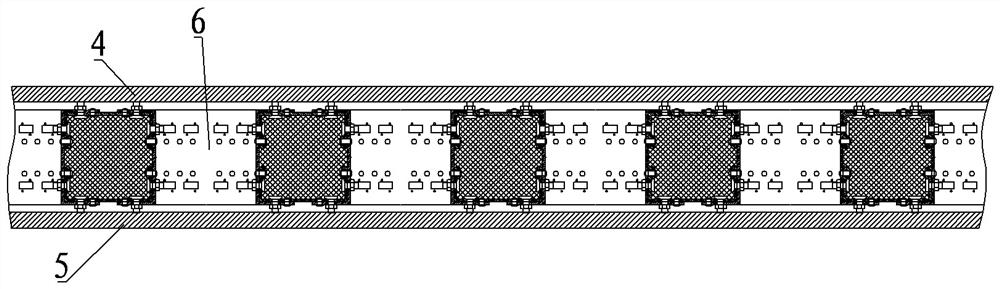

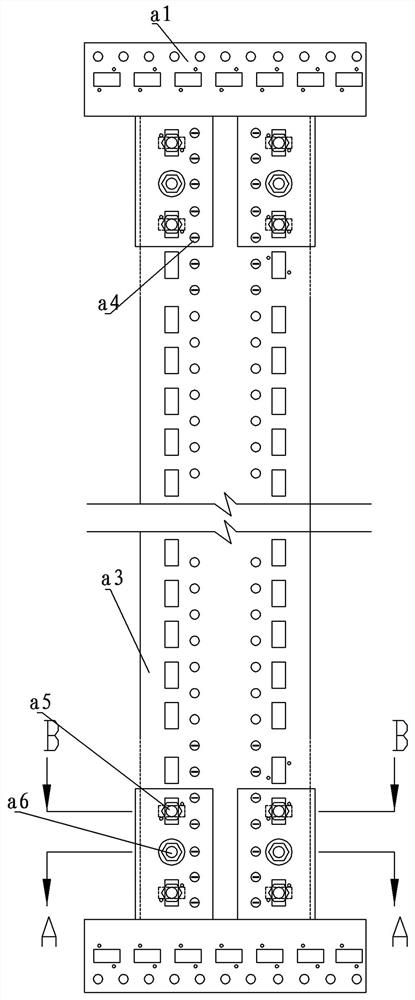

[0026] Embodiment one: see Figure 1-12 , in the figure, a steel structure straw material plate composite floor deck member, including an upper panel, a lower panel and an inner truss body; the upper panel and the lower panel are paved on both sides of the inner truss body, and the feature is: The body is a steel structure straw composite building component connection structure formed by connecting beams, longitudinal beams and inclined beams through end connectors, and filling the gaps between the beams, longitudinal beams and inclined beams with matching straw compression cores;

[0027] The beams, longitudinal beams and oblique beams are steel structure straw composite building components, including two channel-shaped steels with the same length and arranged opposite to each other. The channel-shaped steels include side plates on both sides and webs connected between the side plates , the edge of the side plate is flanged inward, the flanging part is parallel to the side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com