Composite member of steel structure straw material plate

A composite component and steel structure technology, applied in building construction, construction, etc., can solve the problems of self-heavy filling material, low thermal insulation performance, poor construction environment, etc., and achieve high strength, reduce self-weight, and simplify installation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

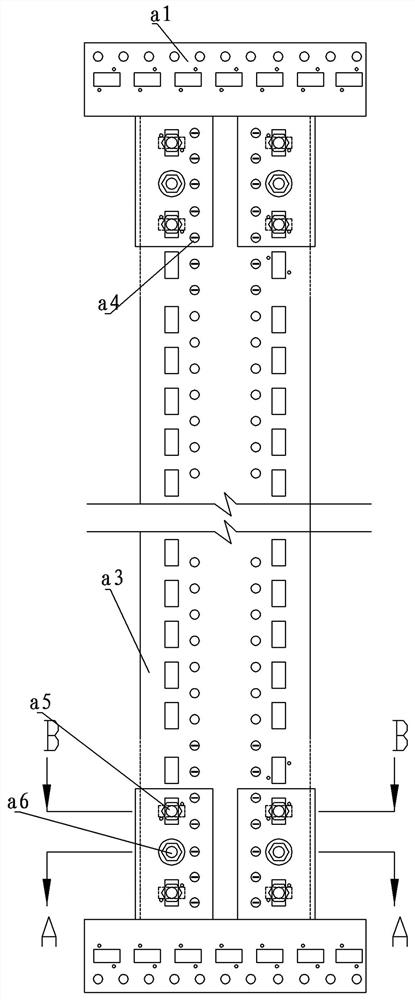

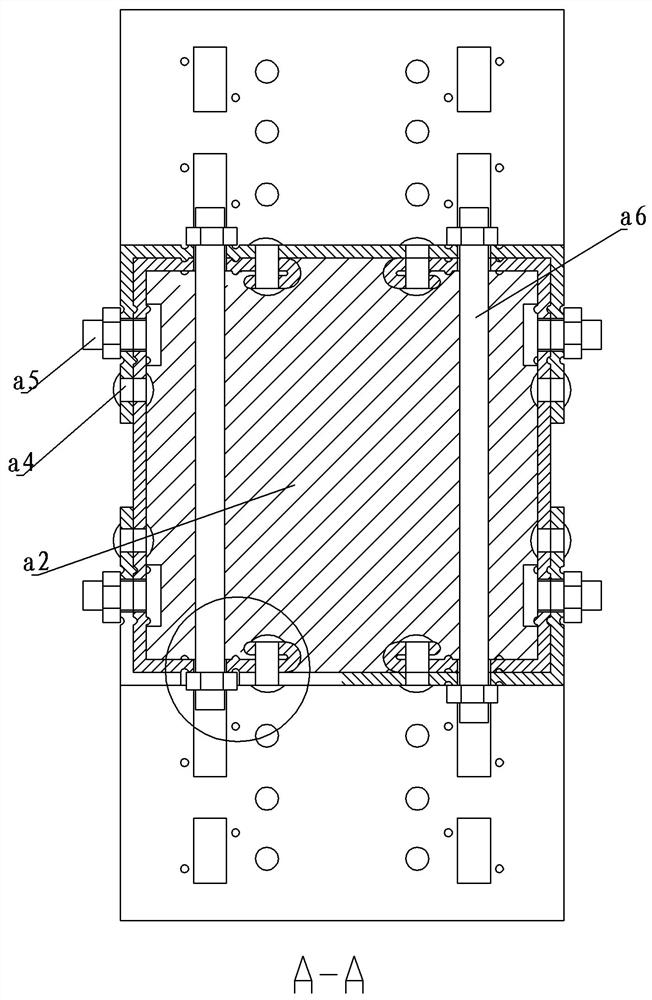

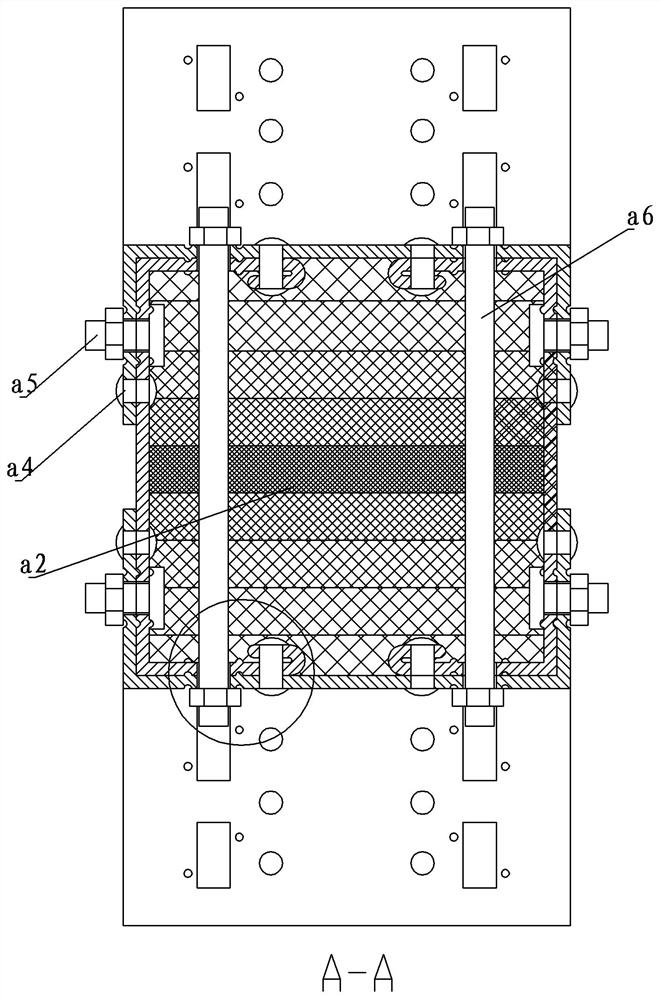

[0037] Embodiment two: see Figure 8-16 In the figure, a steel structure straw material plate composite member includes two channel-shaped steels with the same length and arranged opposite to each other. The channel-shaped steel includes side plates on both sides and webs connected between the side plates. The said The edge of the side plate is flanged inwardly, and the flanging part is parallel to the side plate and there is a gap. The cross-sectional shape of the channel-shaped steel is matched. The plug-in end connector includes two groove-type inserts and end plates. The ends of the two groove-type inserts are fixedly connected to the end plate. The two groove-type inserts The body includes groove side plates and groove bottom plates on both sides. The cross-sectional shape of the groove-type insert body matches the internal cross-sectional shape of the channel-shaped steel. The groove-side plate is inserted into the flange and side plate of the channel-shaped steel In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com