Producing method of calcium fluoride with white carbon black

A production method and technology for silica, applied in the preparation/separation of silica, silica, ammonia, etc., can solve the problems of difficulty in scaling up the batch process, fine silica particles, fine silica particles, etc. The effect of small particle size, large specific surface area and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

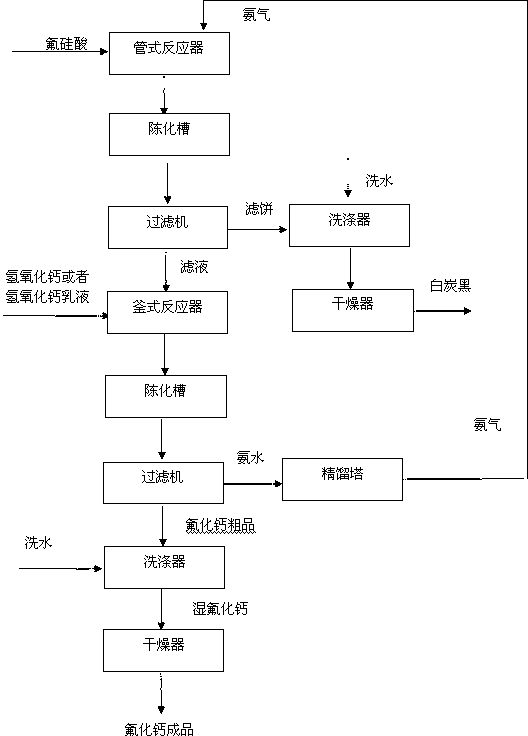

Image

Examples

Embodiment 1

[0018] First pass nitrogen into the tubular reactor, and then pass ammonia into the reactor after 60 seconds. Turn on the fluosilicic acid metering pump, feed 8% fluosilicic acid solution, the feeding speed of fluosilicic acid solution is 0.4 m / s, the residence time of fluosilicic acid is 25 seconds, the feed molar ratio of ammonia gas to fluosilicic acid It is 6.6, after the reaction is completed, the slurry enters the aging tank, and the stirring speed of the aging tank is 50rpm. After aging for 10 minutes, the aging slurry is filtered to obtain white carbon black filter cake and ammonium fluoride solution; white carbon black After the filter cake is washed and dried, a white carbon black product is obtained, and the specific surface area of the white carbon black product is 320m 2 / g, the silicon dioxide content is 98%; the ammonium fluoride solution is passed into the tank reactor, the stirring is started, the stirring speed of the reactor is controlled to be 150rpm, and...

Embodiment 2

[0020] First pass nitrogen into the tubular reactor, and after passing nitrogen for 60 seconds, pass ammonia gas into the reactor. Turn on the fluosilicic acid metering pump, feed 32% fluosilicic acid solution, the feed rate of fluosilicic acid is 0.1 m / s, the residence time of fluosilicic acid is 100 seconds, and the molar ratio of ammonia gas to fluosilicic acid feed is 7.2 , after the reaction was completed, the slurry entered the aging tank, and the aging tank rotating speed was 200rpm. After aging for 120 minutes, the aging slurry was filtered to obtain a white carbon black filter cake and ammonium fluoride solution; the white carbon black filter cake was passed through After washing and drying, a white carbon black product is obtained, and the specific surface area of the white carbon black product is 190m 2 / g, the silica content is 95%; the ammonium fluoride solution is passed into the tank reactor, the stirring is started, the stirring speed of the control reactor i...

Embodiment 3

[0022] First pass nitrogen gas into the tubular reactor, after 60 seconds, pass ammonia gas into the reactor, control the gas velocity of ammonia gas to 10m / s, the residence time of ammonia gas is 1 second, and pass ammonia gas for 30s Finally, turn on the fluosilicic acid metering pump and feed 20% fluosilicic acid solution. The feeding speed of fluosilicic acid solution is 0.16m / s, the residence time of fluosilicic acid is 63 seconds, and the feeding mole of ammonia gas and fluosilicic acid Ratio is 7.2, and after the completion of the reaction, the slurry enters the aging tank, and the aging tank rotating speed is 150rpm. After aging for 60 minutes, the aging slurry is filtered to obtain white carbon black filter cake and ammonium fluoride solution; white carbon black After the filter cake is washed and dried, a white carbon black product is obtained, and the specific surface area of the white carbon black product is 200m 2 / g, the silica content is 96%, the ammonium fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com