Processing method of titanium extraction tailings

A technology for extracting titanium tailings and treatment methods, which is applied to the removal of solid waste, calcium/strontium/barium halides, calcium/strontium/barium chlorides, etc., and can solve the problem of treatment, recycling and utilization of titanium tailings without extraction problems, to achieve the effect of solving difficult problems, realizing reuse, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The experiment was carried out at 30 °C:

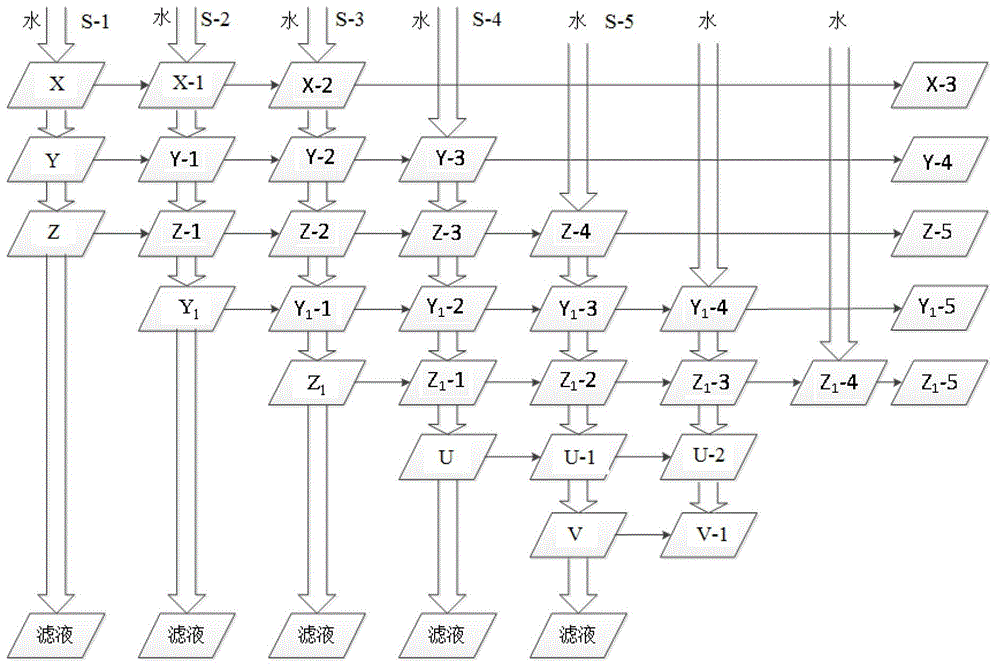

[0040] (1) Take three batches of 500g titanium extraction tailings X, Y, and Z into beakers, and use 500mL tap water S-1 to sequentially wash the titanium extraction tailings X, Y, and Z for 10 minutes, and vacuum Filter under the condition of 0.09Mpa to obtain filter residues X-1, Y-1, and Z-1. The obtained filtrate is recovered to be processed;

[0041] (2) Use 500mL tap water S-2 to stir and wash the filter residues X-1, Y-1, and Z-1 in sequence for 10 minutes respectively, and filter under the condition of a vacuum of 0.09Mpa to obtain the filter residues X-2, Y-2 , Z-2. The obtained filtrate and 500g titanium tailings Y 1 (The fourth batch of titanium extraction tailings) was stirred, washed and filtered to obtain the filter residue Y 1 -1, the obtained filtrate is recovered to be processed;

[0042] (3) Use 500mL tap water S-3 to filter residue X-2, Y-2, Z-2 and Y in sequence 1 -1 were stirred and washed for 10 minu...

Embodiment 2

[0046] (1) Take 1500g of titanium extraction tailings X into a beaker, stir and wash with 1500mL tap water for 10min and filter to obtain filter residue X-1. The obtained filtrate is recovered to be processed;

[0047] (2) The filter residue X-1 was stirred and washed with 1500 mL of tap water for 10 min and then filtered to obtain the filter residue X-2. The obtained filtrate is recovered to be processed;

[0048] (3) The above filter residue X-2 was stirred and washed with 1500 mL of tap water for 10 min and then filtered to obtain filter residue X-3. Wherein, after drying the filter residue X-3, a titanium extraction tailings product having a chlorine element content of 0.05% by weight is obtained.

[0049] (4) Combine the above filtrates and place them until the natural evaporation volume is about 1000 ml. Add milk of lime to the filtrate to be treated continuously and slowly under stirring to adjust the pH of the filtrate to 10. After stirring for 5 minutes, remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com