Wet etch process and composition for forming openings in a polymer substrate

a polymer substrate and wet etching technology, applied in the field of microelectronic elements, can solve the problems of increasing manufacturing costs, time-consuming two-step laser ablation process, and laser ablation generally can only process one substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In describing the preferred embodiments of the present invention, specific terminology will be resorted to for the sake of clarity. However, the invention is not intended to be limited to the specific terms so selected, and is to be understood that each specific term includes all technical equivalence which operate in a similar manner to accomplish a similar purpose.

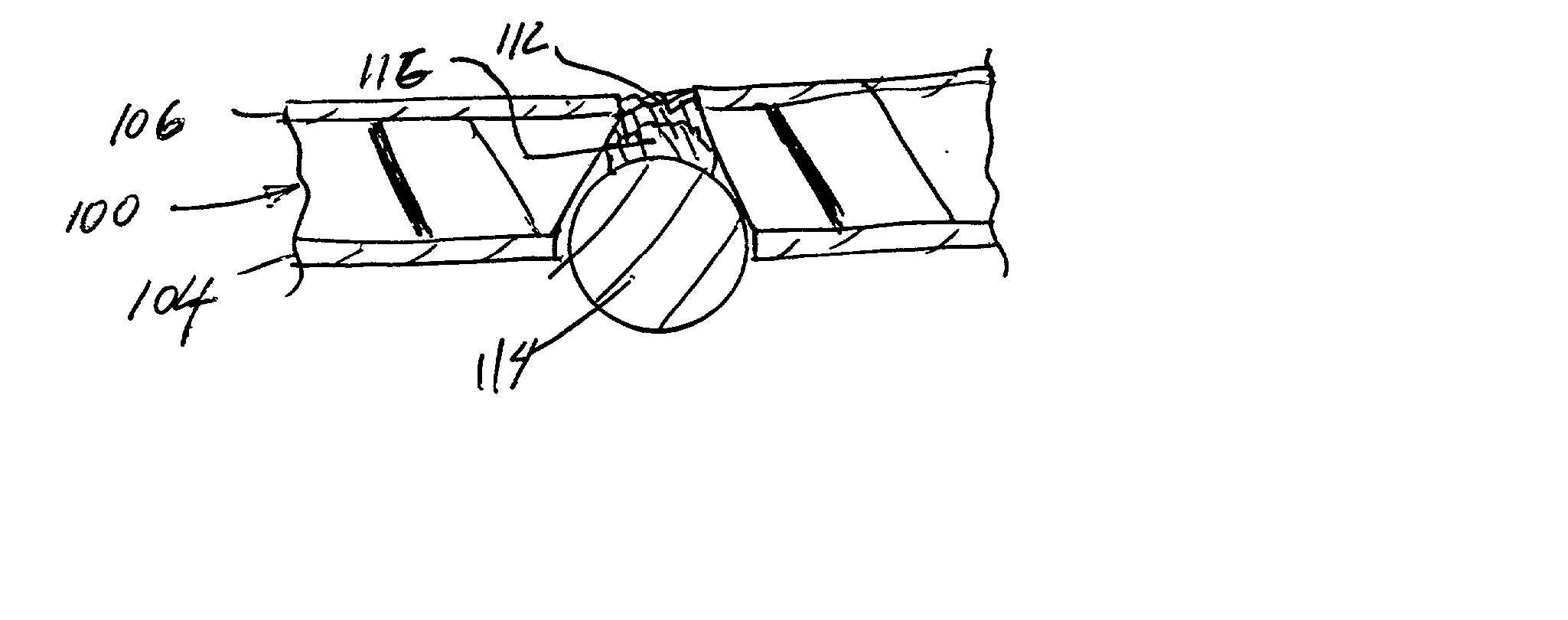

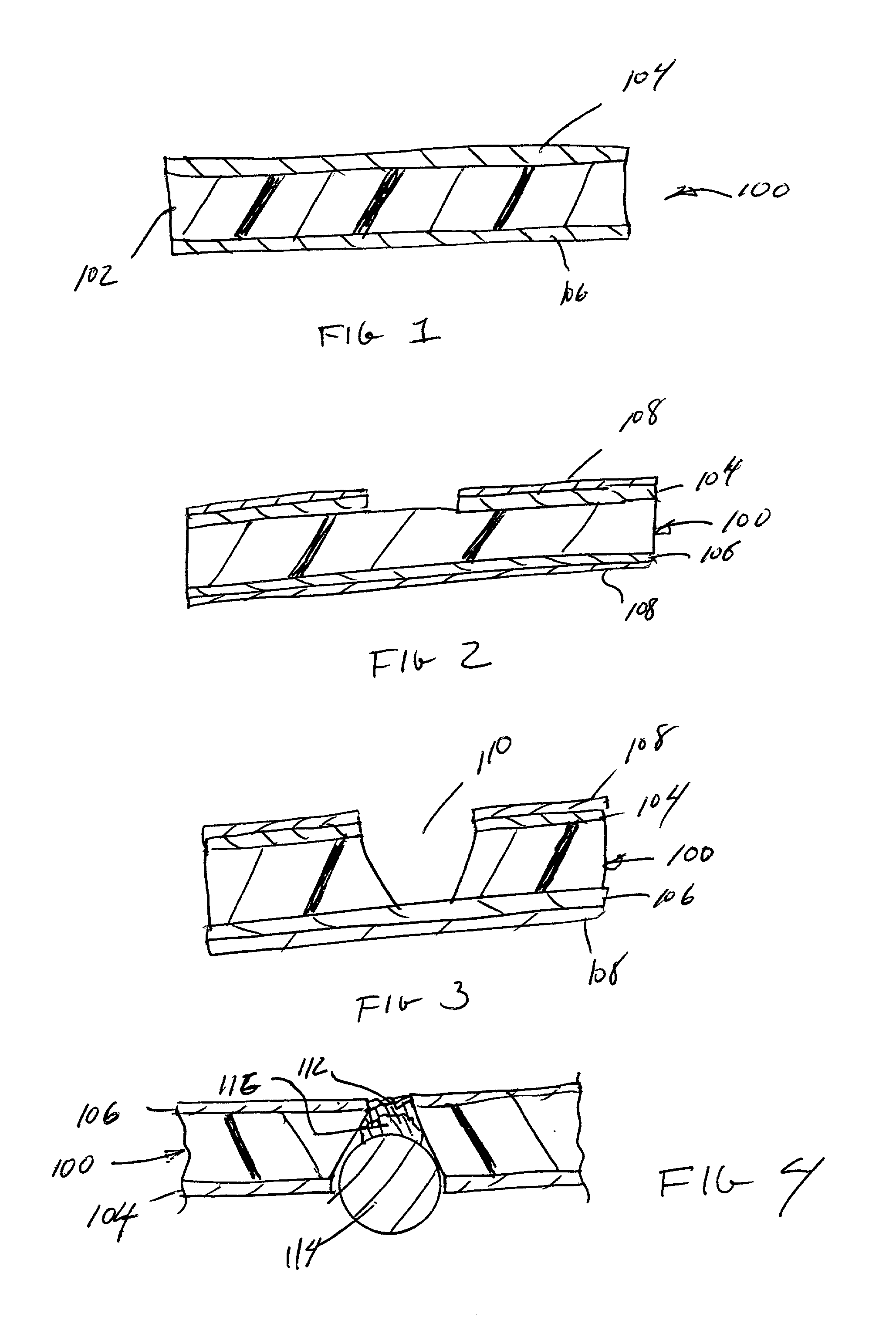

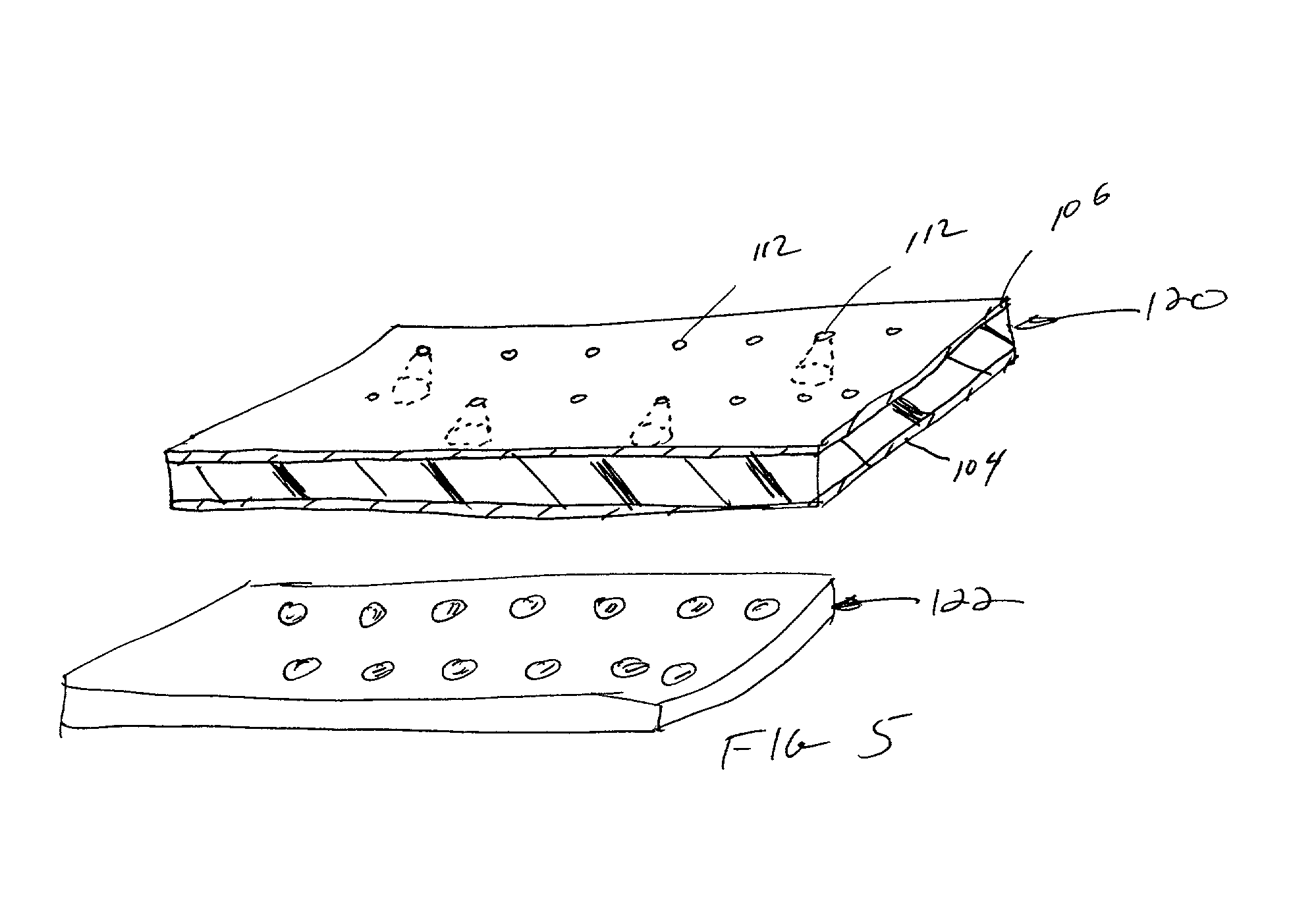

[0020] In accordance with the present invention, there is disclosed a chemical etching process and chemical etchant composition for wet chemical etching of polymer substrates, e.g., polyimide, to form openings such as bond windows, vias and other holes, and particularly, micro-vias, i.e., an opening having a diameter of about 100 microns or less, for interconnecting layers in flexible circuit structures of microelectronic elements. The etching process and etchant compositions are broadly based upon the presence of at least one dihydric alcohol and a strong base such as one or more hydroxide compounds.

[0021] Dihydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com