Manufacturing method of high-compaction lithium battery positive electrode material nickel cobalt lithium manganate

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of not being able to increase the compaction density, achieve high cost performance, enhance compactness, and increase single crystal particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Material preparation: select 1 kg of nickel hydroxide, cobalt and manganese (nickel: cobalt: manganese = 5:2:3), and calculate the corresponding battery grade lithium carbonate and strontium hydroxide according to the molar ratio of metal content 1: 1.1 and 1: 0.003 ;

[0033] (2) Lithium mixing: mix the three raw materials evenly;

[0034] (3) High-temperature calcination: the mixed product is placed in a high-temperature kiln for calcination, the calcination temperature is 900-950 ℃, and the calcination time is 14 hours;

[0035] (4) After calcination, the product is crushed and crushed to obtain a finished product.

Embodiment 2

[0037] (1) Material preparation: select 1 kg of nickel hydroxide, cobalt and manganese (nickel: cobalt: manganese = 5:2:3), and calculate the corresponding battery grade lithium carbonate and strontium hydroxide according to the molar ratio of metal content 1: 1.1 and 1: 0.005 ;

[0038] (2) Lithium mixing: mix the three raw materials evenly;

[0039] (3) High-temperature calcination: the mixed product is placed in a high-temperature kiln for calcination, the calcination temperature is 900-950 ℃, and the calcination time is 14 hours;

[0040] (4) After calcination, the product is crushed and crushed to obtain a finished product.

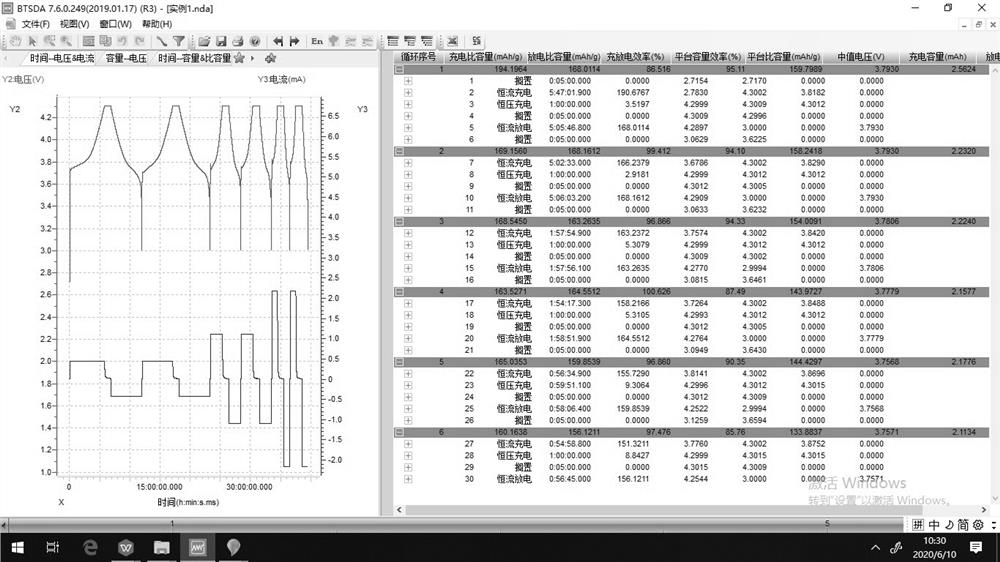

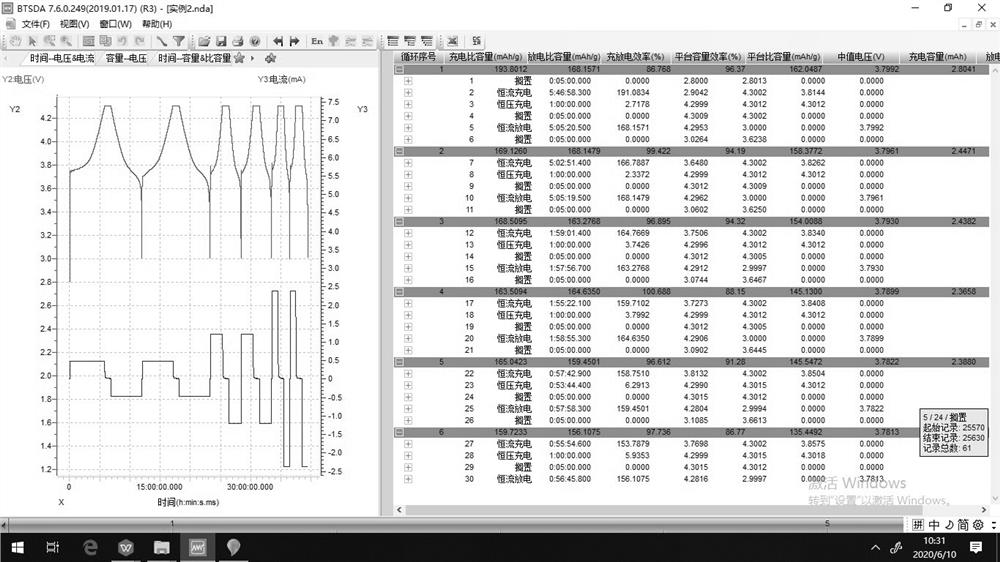

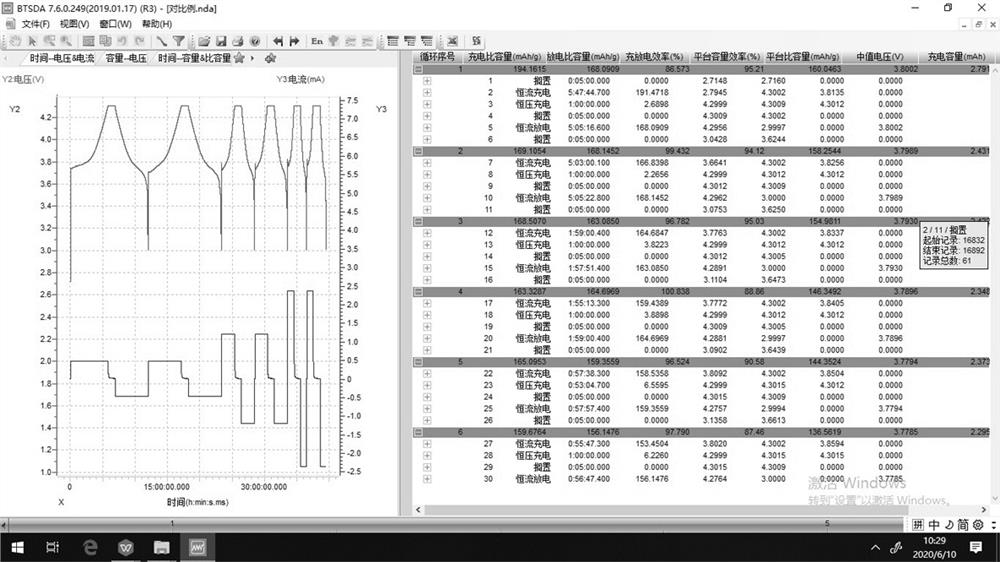

[0041] Comparative example and embodiment detection parameter are as follows table 1.

[0042] Table 1 Parameters of compaction density test

[0043]

[0044] The compaction density after passing through the roller machine is as follows: comparative example: 3.61g / cm³, embodiment 1: 3.68g / cm³, embodiment 2: 3.75g / cm³.

[0045] See the accompanyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com