High-efficiency solar packaging film

A solar energy encapsulation and high-efficiency technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of increasing the cost of solar cell components, unsatisfactory photoelectric conversion efficiency, and poor use effect Ideal and other issues, to achieve the effect of improving photoelectric conversion efficiency, reducing requirements, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

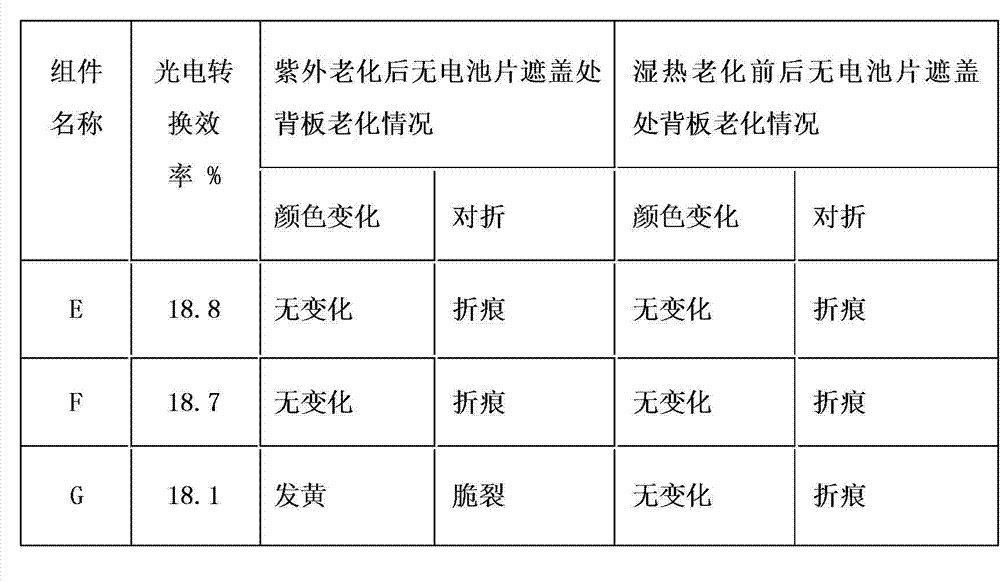

Examples

Embodiment 1

[0015] Embodiment 1: A high-efficiency solar energy encapsulation adhesive film, including an upper adhesive film and a lower adhesive film, the thickness of the upper adhesive film is 200 μm, and the thickness of the lower adhesive film is 300 μm. Wherein the upper adhesive film mainly includes 100 parts by mass of EVA resin, 2-ethylhexyl peroxide tert-butyl carbonate, 1.5 parts of 2-ethylhexyl tert-butyl oxide, and 1 part of trimethylolpropane trimethacrylate. 1 part, 1 part of γ-methacryloxypropyl trimethoxysilane coupling agent and 0.5 part of stability aid, the upper layer of adhesive film can further include one or more conventional additives in this field as required, the Conventional additives include, but are not limited to, processing aids and flame retardants. The lower film mainly includes 100 parts by mass of EVA resin, 1.5 parts of tert-butyl peroxide 2-ethylhexyl carbonate, 1 part of trimethylolpropane trimethacrylate, 10 parts of titanium dioxide and 1 part of ...

Embodiment 2

[0017] Embodiment 2: A high-efficiency solar energy encapsulation adhesive film, including an upper adhesive film and a lower adhesive film, the thickness of the upper adhesive film is 100 μm, and the thickness of the lower adhesive film is 450 μm. The upper film mainly includes 100 parts by mass of EVA resin, 1.2 parts of tert-butyl peroxide 2-ethylhexyl carbonate, 0.6 parts of trimethylolpropane trimethacrylate, γ-methacryloxypropane 0.8 parts of trimethoxysilane coupling agent, 0.8 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate and tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] 0.8 part of pentaerythritol ester, the upper film can further include one or more conventional additives in the field according to needs, the conventional additives include but not limited to processing aids and flame retardant agent. The lower film mainly includes 100 parts by mass of EVA resin, 1.2 parts of tert-butyl peroxide 2-ethylhexyl carbonate, 0.6 parts of trimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com