Super-hydrophobic nano coating and preparation method thereof

A nano-coating, super-hydrophobic technology, applied in coatings and other directions, can solve problems such as complexity, poor practicability, and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

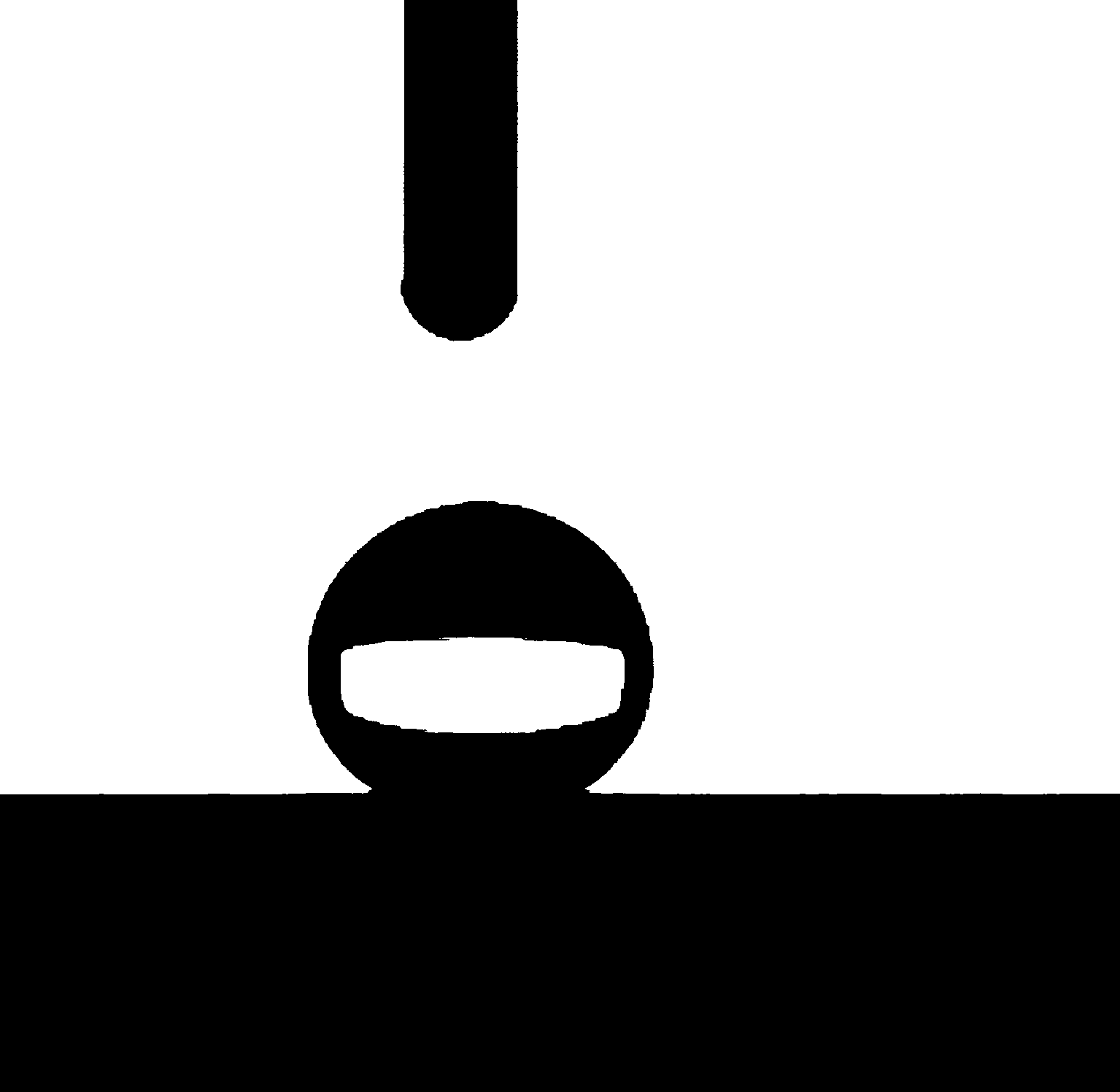

Image

Examples

Embodiment 1

[0026] Add 3 parts of titanium dioxide, 2 parts of silicon dioxide, 0.1 part of BYK180 and 0.2 parts of solvent-based polyurethane dispersant to 100 parts of absolute ethanol, stir thoroughly for 2 hours, and then ultrasonically disperse for 20 minutes to obtain a dispersion of titanium dioxide and silicon dioxide ;

[0027] Mix the above dispersion with 50 parts of silicone, add 0.8 parts of curing agent at the same time, stir and ultrasonically disperse into a uniform coating;

[0028] Spin coating is applied on the pre-cleaned glass sheet, and the number of spin coating is 2 times; then the glass sheet is dried in an oven at 70°C.

[0029] The contact angle of the prepared glass surface with water was 155°, and the rolling angle was 6°.

Embodiment 2

[0031] Add 6 parts of titanium dioxide, 8 parts of silicon dioxide, 0.2 parts of BYK180 and 0.56 parts of solvent-based polyurethane dispersant to 150 parts of absolute ethanol, add 5 mm zirconium beads, and disperse at high speed in a sand mill disperser for 2 hours to obtain titanium dioxide and Silica dispersion;

[0032] Mix the above dispersion with 50 parts of silicone, add 0.8 parts of curing agent at the same time, and continue to disperse into a uniform coating;

[0033] It is coated on the pre-cleaned glass sheet by dip coating, and then dried in an oven at 70°C.

[0034] The contact angle of the prepared glass surface with water was 153.5°, and the rolling angle was 7°.

Embodiment 3

[0036] Add 3 parts of titanium dioxide, 2 parts of silicon dioxide, 5 parts of barium sulfate, 0.1 part of BYK180 and 0.4 parts of solvent-based polyurethane dispersant into 100 parts of absolute ethanol, stir thoroughly for 2 hours, and then ultrasonically disperse for 20 minutes to obtain filler particles. Dispersions;

[0037] Mix the above dispersion with 50 parts of silicone, add 0.8 parts of curing agent at the same time, stir and ultrasonically disperse into a uniform coating;

[0038] Spin coating is applied on the pre-cleaned glass sheet, and the number of spin coating is 2 times; then the glass sheet is dried in an oven at 70°C.

[0039] The contact angle of the prepared glass surface with water was 149°, and the rolling angle was 9°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com