Method for enhancing alkaline hydrogen peroxide to pretreat lignocellulose by ultrasonic wave

A technology of lignocellulose and hydrogen peroxide, applied in the field of biomass resource utilization, can solve the problems of difficult lignin reduction and insufficient attention to lignin recycling, so as to reduce hindrance, save energy and Investment cost, effect of increasing ethanol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

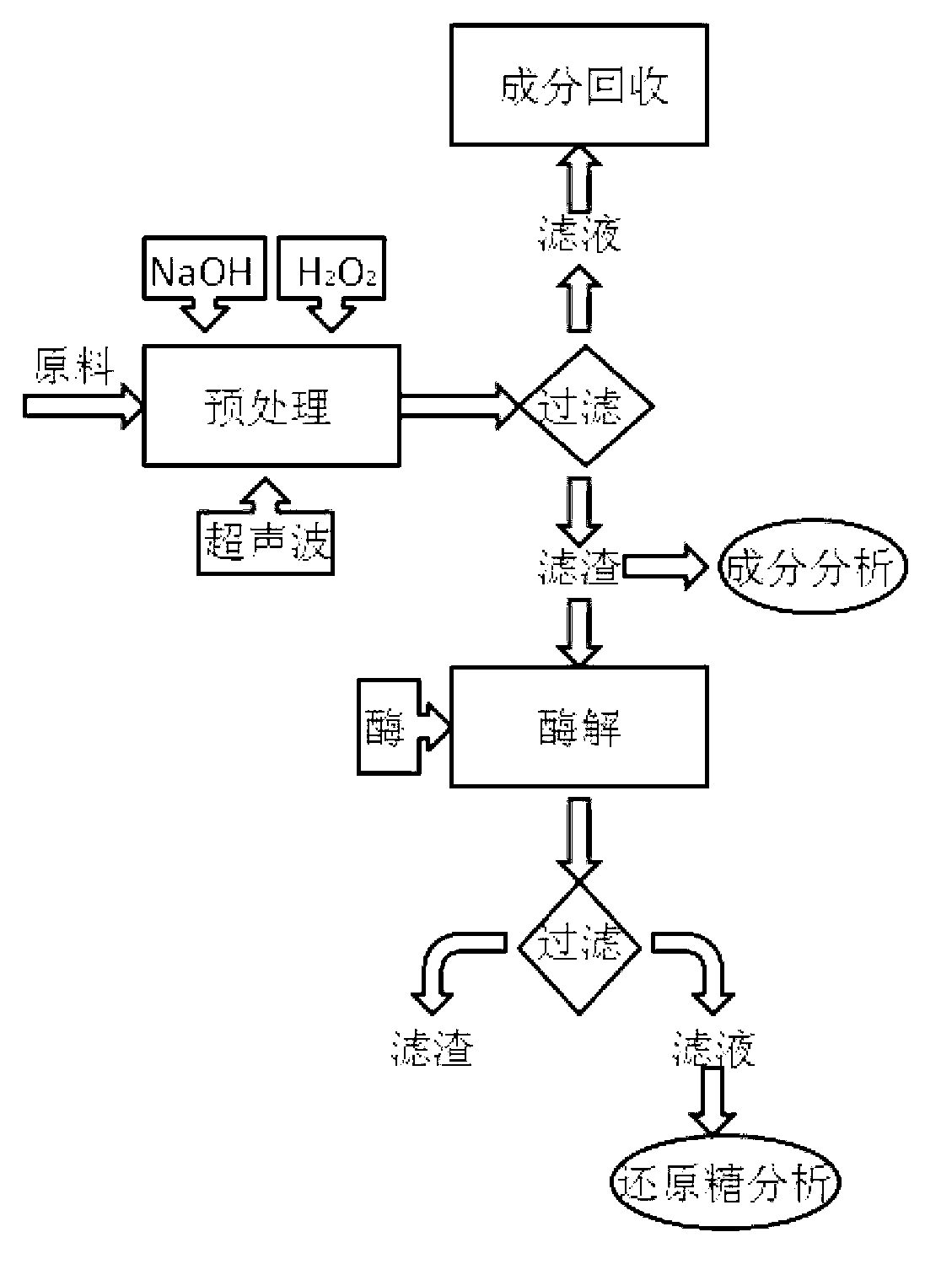

Method used

Image

Examples

Embodiment 1

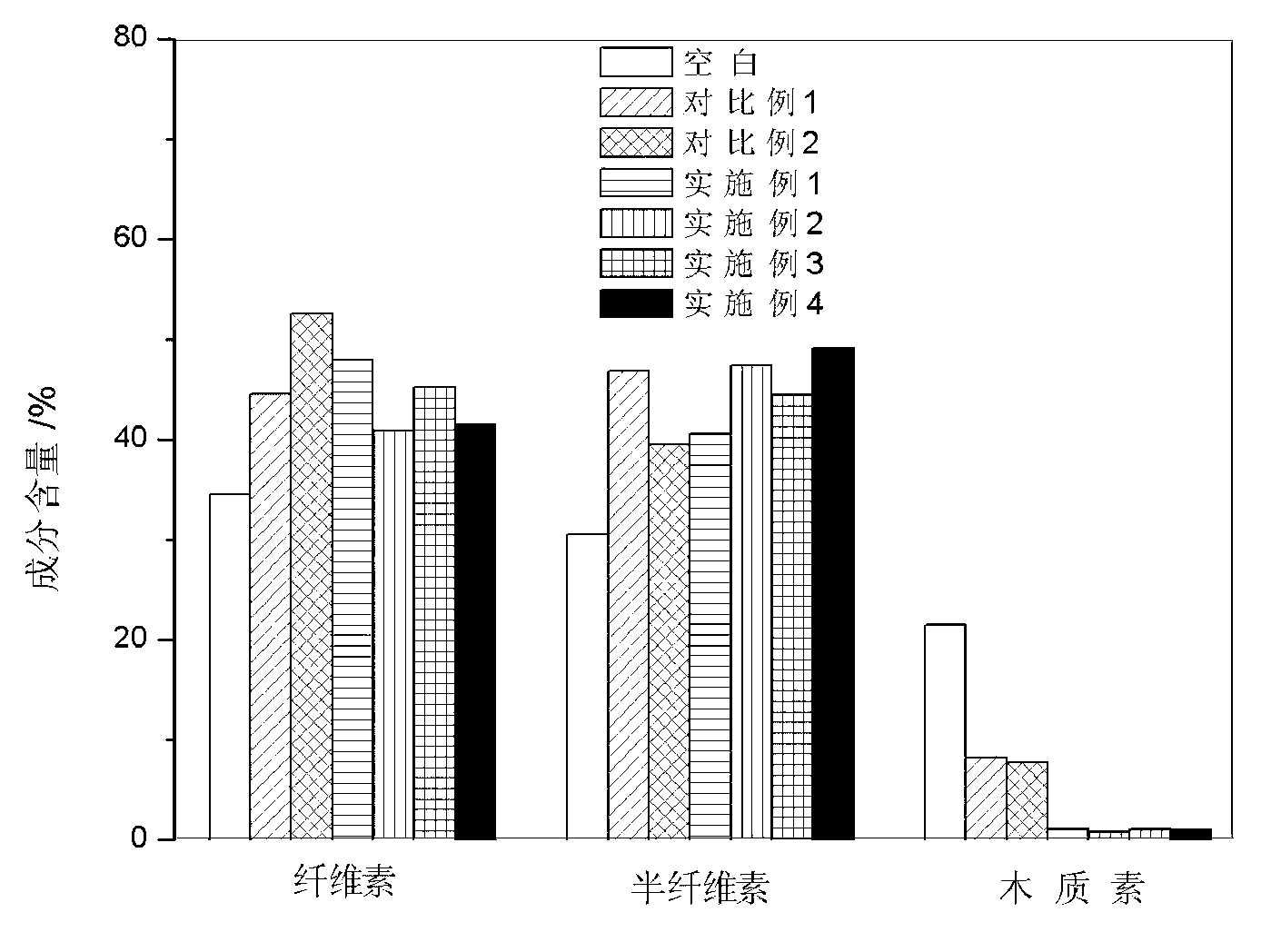

[0032] Weigh 10g of dried corn cobs through a 40-mesh sieve, add 100ml, 0.25mol / L NaOH solution and 3.3ml 30% (v / v) H 2 o 2 Place it in a beaker and perform ultrasonic action at the same time. The applied power of ultrasonic wave is 120W, the action temperature is 25°C, and the total ultrasonic time is 40min. After the reaction, the slurry was subjected to vacuum filtration to achieve solid-liquid separation, and the filter residue generated above was repeatedly washed with distilled water until the pH value was neutral, and dried at 105° C. to constant weight.

[0033] Carry out paradigm analysis method (Van Soest) to measure the corn cob that pretreatment obtains (main components such as figure 2 shown) and enzymolysis, wherein the enzymolysis conditions are: solid-liquid ratio 1:70 (g / mL), time 72h, temperature 50°C, pH 4.8 citric acid-sodium citrate buffer solution, cellulase Produced by Trichoderma reesei at a loading of 20 FPU / g dry material. After the enzymatic hydr...

Embodiment 2

[0035] Weigh 10g of corncobs after passing through a 40 mesh sieve and drying, add 100ml, 0.25mol / L NaOH solution into the beaker, and carry out ultrasonic wave at the same time. The time is 40min, and 3.3ml of 30% (v / v) H 2 o 2 . After the reaction, the slurry was subjected to vacuum filtration to realize solid-liquid separation, and the filter residue generated above was repeatedly washed with distilled water until the pH value was neutral, and dried at 105° C. to constant weight.

[0036] Carry out paradigm analysis method (Van Soest) to measure the corn cob that pretreatment obtains (main components such as figure 2 shown) and enzymatic hydrolysis, wherein the enzymatic hydrolysis conditions are: solid-liquid ratio 1:70 (g / mL), time 72h, temperature 50°C, pH 4.8 citric acid-sodium citrate buffer solution, cellulase Produced by Trichoderma reesei at a loading of 20 FPU / g dry material. After the enzymatic hydrolysis, the reaction slurry was taken out, inactivated in a b...

Embodiment 3

[0038] Weigh 10g of corn cobs after passing through a 40-mesh sieve and drying, add 100ml, 0.25mol / L NaOH solution into the beaker, and perform ultrasonic action at the same time. The time is 40min, and 3.3ml of 30% (v / v) H 2 o 2 . After the reaction, the slurry was subjected to vacuum filtration to realize solid-liquid separation, and the filter residue generated above was repeatedly washed with distilled water until the pH value was neutral, and dried at 105° C. to constant weight.

[0039] Carry out paradigm analysis method (Van Soest) to measure the corn cob that pretreatment obtains (main components such as figure 2 shown) and enzymatic hydrolysis, wherein the enzymatic hydrolysis conditions are: solid-liquid ratio 1:70 (g / mL), time 72h, temperature 50°C, pH 4.8 citric acid-sodium citrate buffer solution, cellulase Produced by Trichoderma reesei at a loading of 20 FPU / g dry material. After the enzymatic hydrolysis, the reaction slurry was taken out, inactivated in a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com