Process for preparing composite lithium base grease

A technology of base grease and lithium complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-4 and comparative example 1-2

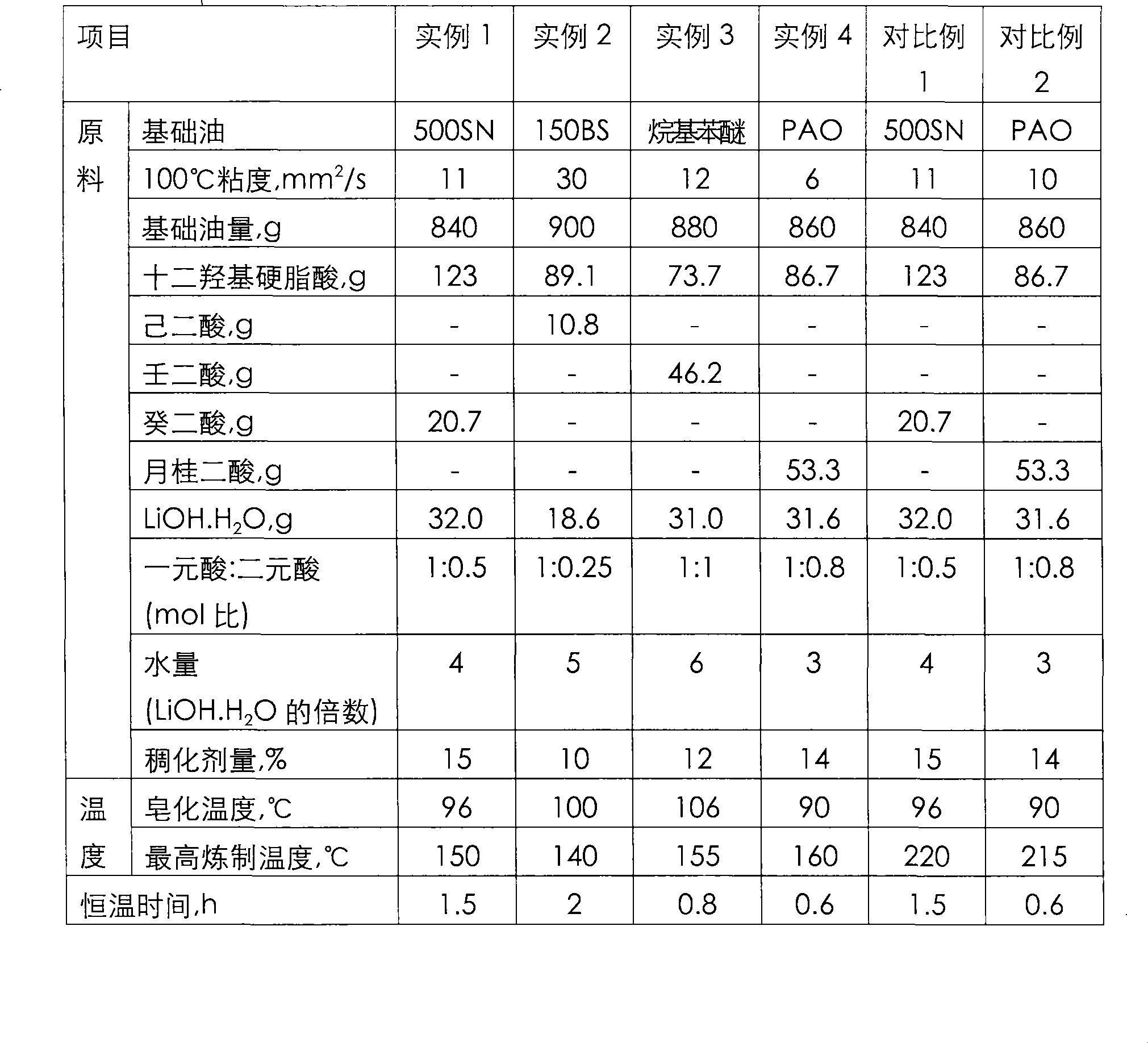

[0021] Prepare lithium complex grease according to the raw materials and reaction conditions shown in Table 1: add the base oil into the saponification kettle, then add 12-hydroxystearic acid and dibasic acid into the saponification kettle, heat and stir, and gradually make the temperature reach the saponification temperature Slowly add the dissolved lithium hydroxide aqueous solution into the saponification kettle, fully stir for saponification and dehydration; after rising to the highest refining temperature, refine at a constant temperature for a period of time, then add the remaining base oil to quench the lubricating grease in the kettle, and the temperature drops When it reaches about 100°C, after grinding, a high dropping point lithium complex grease is made. The performance of lithium complex grease is shown in Table 2.

[0022] Table 1:

[0023]

[0024] Raw material molecular weight:

[0025] Lauryl hydroxystearic acid, g / mol 300.48

[0026] Adipic acid, g / mol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com