p-CuO-n-ZnO solar cell and preparation method of p-CuO-n-ZnO solar cell

A solar cell and electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as all-inorganic depletion layer heterojunction solar cells that no one has reported, and achieve improved photoelectric conversion efficiency, simple equipment, and low thermal emission. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

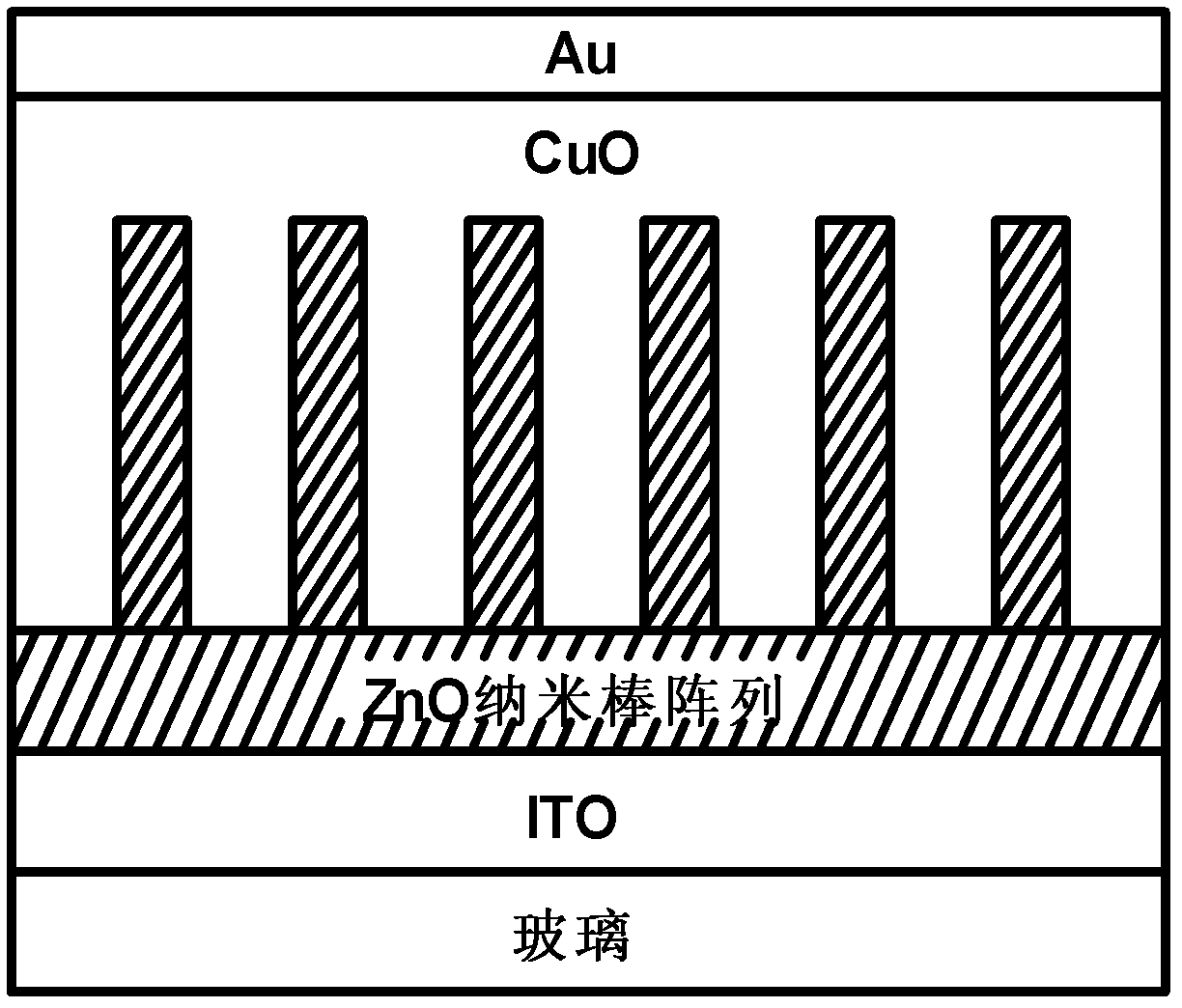

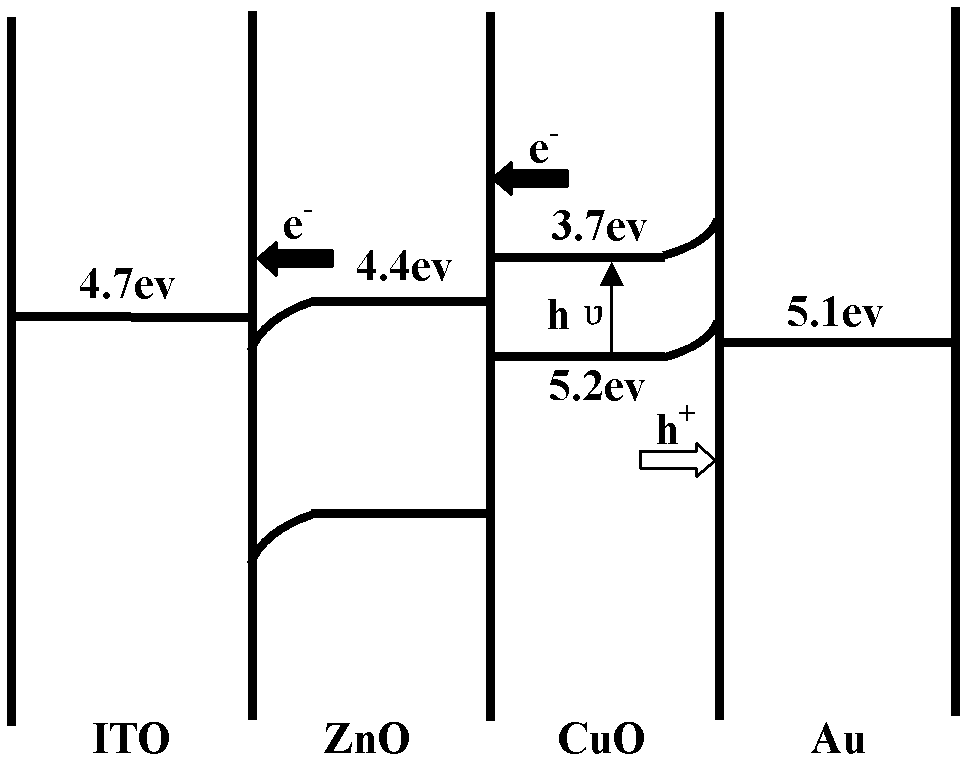

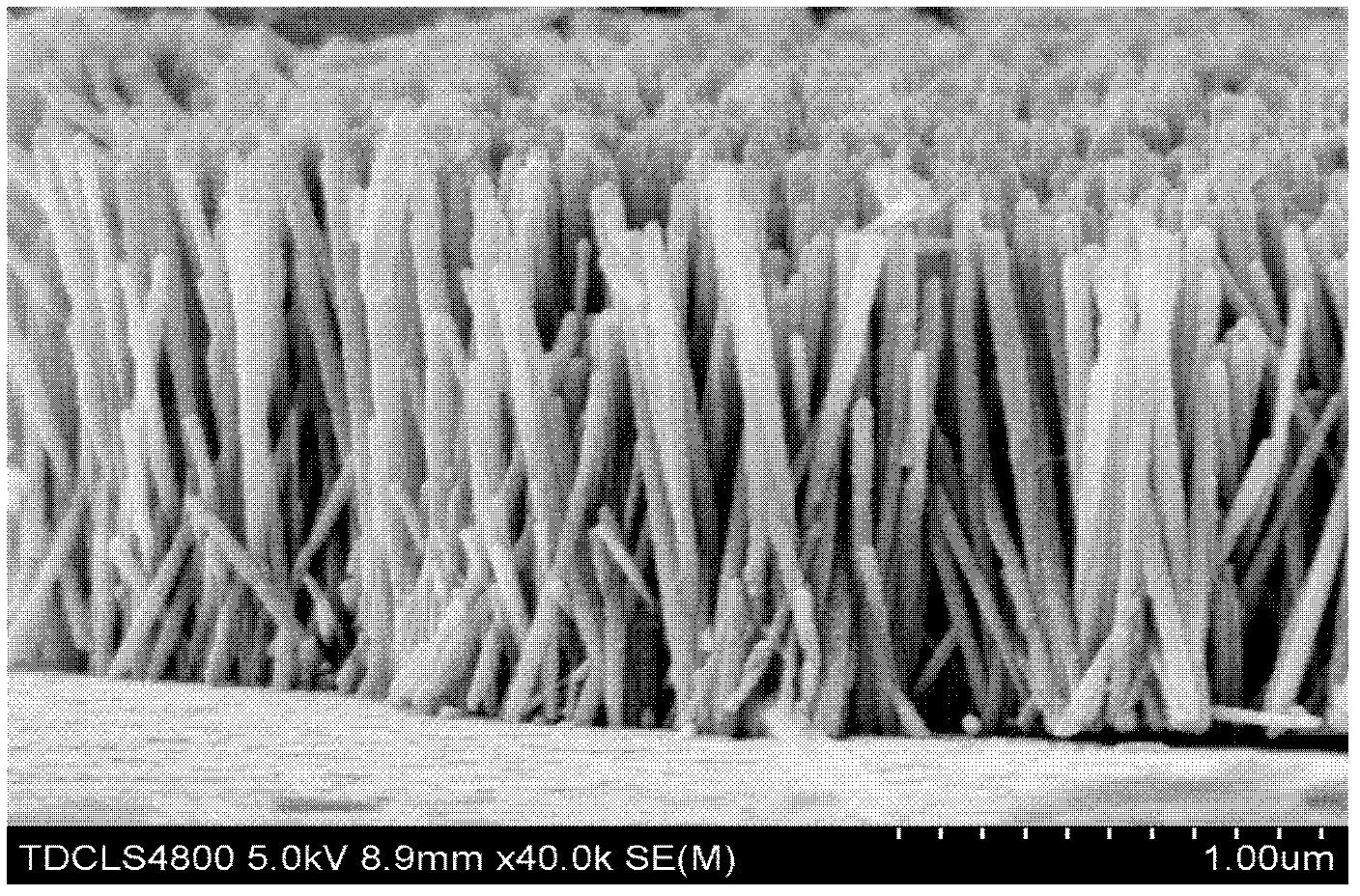

[0027] A p-CuO-n-ZnO solar cell, such as figure 1 As shown, the bottom layer to the top layer are sequentially stacked as an ITO substrate, a vertically oriented ZnO nanorod array, a CuO thin film, and an Au electrode, where the vertically oriented ZnO nanorod array acts as an n-type semiconductor absorber layer, and the CuO thin film acts as a p-type semiconductor light absorber layer and hole transport layer.

[0028] A preparation method of the p-CuO-n-ZnO solar cell, the steps are as follows:

[0029] 1) The ZnO seed layer was prepared on ITO by sol-gel method: 5.4875g of Zn(CH 3 COO) 2 2H 2 O was dissolved in 50ml of ethylene glycol methyl ether, and then 1.5ml of ethanolamine (ethanolamine and Zn(CH 3 COO) 2 2H 2 The molar ratio of O is 1:1), heated in a water bath at 70°C for 3 hours to form a ZnO sol with a zinc ion concentration of 0.5mol / L, aged for 12 hours, and then spun the ZnO sol at a speed of 4000 rpm Coated on the surface of a cleaned ITO substrate, ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com