Back contact solar cell string, preparation method, assembly and system

A technology for solar cells and battery modules, applied in the field of solar cells, can solve problems such as complex cell string processes, and achieve the effect of solving precise alignment and complex processes, simplifying processes, and reducing the requirements for precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

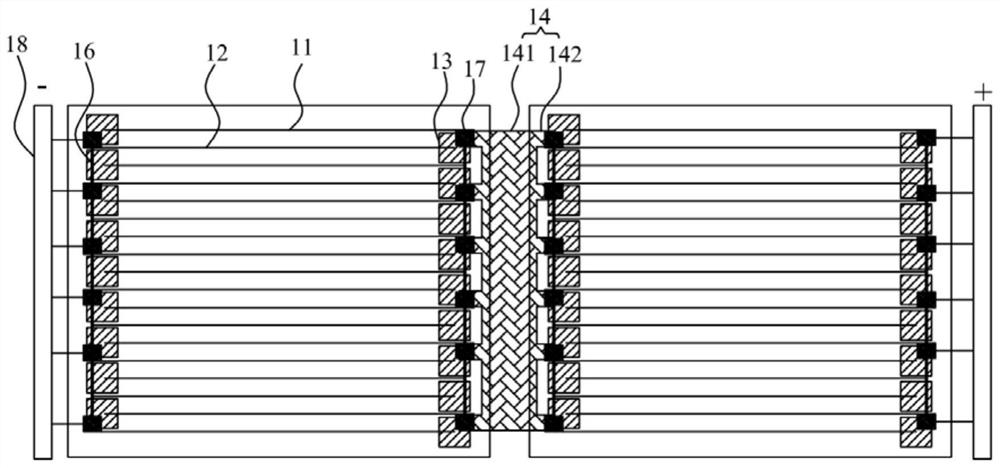

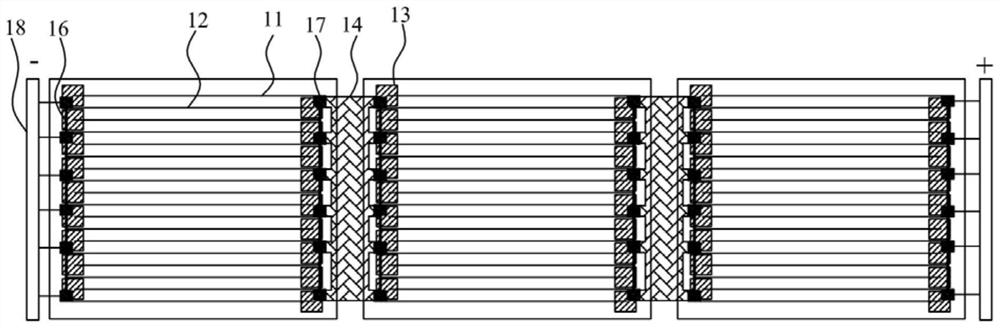

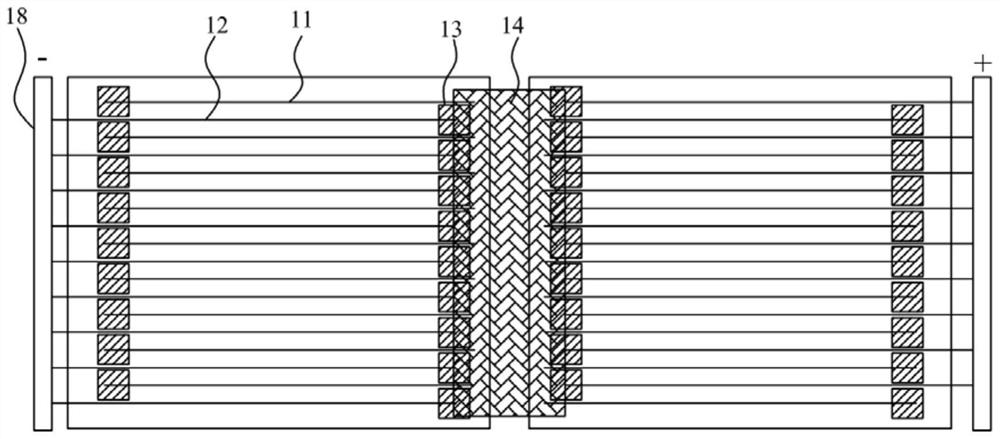

[0049] see figure 1 , is a schematic structural diagram of a back-contact solar cell string provided by an embodiment of the present invention. For convenience of description, only the parts related to the embodiment of the present invention are shown. The back-contact solar cell string provided by the embodiment of the present invention includes:

[0050] At least two battery sheets, each battery sheet includes alternately arranged positive electrode regions 11 and negative electrode regions 12;

[0051] An insulating layer 13 covering each positive electrode region 11 on one side of the battery sheet and each negative electrode region 12 on the other side of the battery sheet; and

[0052] Connecting the first bus bar 14 of two adjacent battery sheets, the first bus bar 14 is electrically connected to each positive electrode region 11 and negative electrode region 12 not covered by the insulating layer 13 in the two adjacent battery sheets.

[0053] Wherein, in one embodiment...

Embodiment 2

[0067] see Figure 7 , is a schematic flow chart of a method for preparing a back-contact solar cell string provided by the second embodiment of the present invention. For the convenience of illustration, only the parts related to the embodiment of the present invention are shown. This preparation method is used to prepare The back contact solar cell string, specifically, the method includes:

[0068] Step S11, respectively setting insulating layers on each positive electrode area on one side of the battery sheet and each negative electrode area on the other side of the battery sheet;

[0069] Among them, in one embodiment of the present invention, such as Figure 1 to Figure 5 As shown, a positive electrode region and a negative electrode region are arranged at intervals on the back of the battery sheet, wherein the positive electrode region includes a P-type doped region and a positive electrode thin grid line arranged on the P-type doped region, and the negative electrode ...

Embodiment 3

[0090] The third embodiment of the present invention also provides a battery assembly, which includes the back-contact solar cell string described in the foregoing embodiments.

[0091] Specifically, the assembly process of the battery assembly includes the following:

[0092] Battery sorting: Due to the strong randomness of the solar cell production line, the performance of the produced cells is not the same. In order to effectively combine cells with the same or similar performance, it should be based on the results measured by the battery test. The performance parameters are classified to improve the utilization rate of cells and make qualified cell components. Battery testing is to test the output parameters (current and voltage) of the battery.

[0093] Series connection: each battery sheet is prepared according to the preparation method described in the foregoing method embodiment, so that it is connected in series to form the battery string described in the foregoing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com