Porous hydrogel film for extracting uranium from seawater and preparation method of porous hydrogen film

A technology of porous hydrogel and thin film, applied in chemical instruments and methods, other chemical processes, improvement of process efficiency, etc., can solve the problems of difficulty in quickly obtaining materials for extracting uranium in batches, complicated process, high equipment cost, etc., and achieve the goal of preparing The effect of short time, simple process and enhanced uranium extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A preparation method of a porous hydrogel membrane for extracting uranium from seawater, comprising the following steps:

[0024] (1) Preparation of sol: first weigh 13g of hydroxylamine hydrochloride and place it in a round bottom flask, add 100mL N-N dimethylformamide solution, stir at room temperature until completely dissolved, then add 10g of anhydrous sodium carbonate, stir at room temperature for 2h to adjust the pH of the reaction solution 6, then add 10g of polyacrylonitrile and stir for 30min until the solution is uniform without agglomeration, then heat in an oil bath at 65°C, and magnetically stir the oximation reaction at a speed of 250rmp / min for 12h to obtain amidoximated polyacrylonitrile PAO Sol.

[0025] (2) Film formation and separation: Put the glass substrate into a beaker filled with acetone and alcohol in order to clean it ultrasonically (100HZ, 15min), clean it with ultrapure water and dry it for later use, and drop the PAO sol into...

Embodiment 2

[0027] Embodiment two: material performance test

[0028] The basic amidoximated polyacrylonitrile hydrogel film prepared in Example 1 is tested by BET test method, and its specific surface area is 16.7283 ± 0.050m 2 / g, the tensile strength can reach 0.12MPa.

[0029] The morphology of alkaline amidoximated polyacrylonitrile hydrogel film was observed by SEM electron microscope, and there were a large number of uniform micropores with a pore diameter of about 10 μm.

Embodiment 3

[0030] Example 3: Test of Uranium Extraction Effect

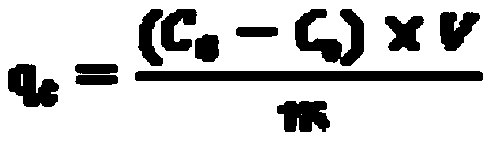

[0031] Soak in 500ml of simulated seawater with a pH=6 uranium concentration of 8ppm, adsorb for 36 hours, and use ICP-OES inductively coupled plasma optical emission spectrometer to measure the concentration of uranium before and after adsorption. The formula for calculating the adsorption capacity is as follows:

[0032]

[0033] where q t Indicates the amount of uranium extracted within t time, C 0 Indicates the initial concentration of uranium; C t Indicates the concentration of uranium at time t; V indicates the volume of seawater tested; m indicates the mass of adsorbent.

[0034] The results of the uranium extraction test are shown in Table 2. The experimental results show that the porous nano-film material prepared by the coating method has an adsorption rate of uranium as high as 375 mg / g. After cleaning and repeating the above uranium extraction steps, it shows that the prepared film can be reused for uraniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com