Preparation method for composite yarn with radiation refrigeration function, and fabric

A technology of radiative cooling and composite yarn, applied in yarn, textile, papermaking, textile and other directions, can solve the problems of low mass fraction of functional fillers, inability to effectively block the input heat radiation of solar radiation, and limit the effect of radiation cooling. The effect of short, excellent radiation refrigeration performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

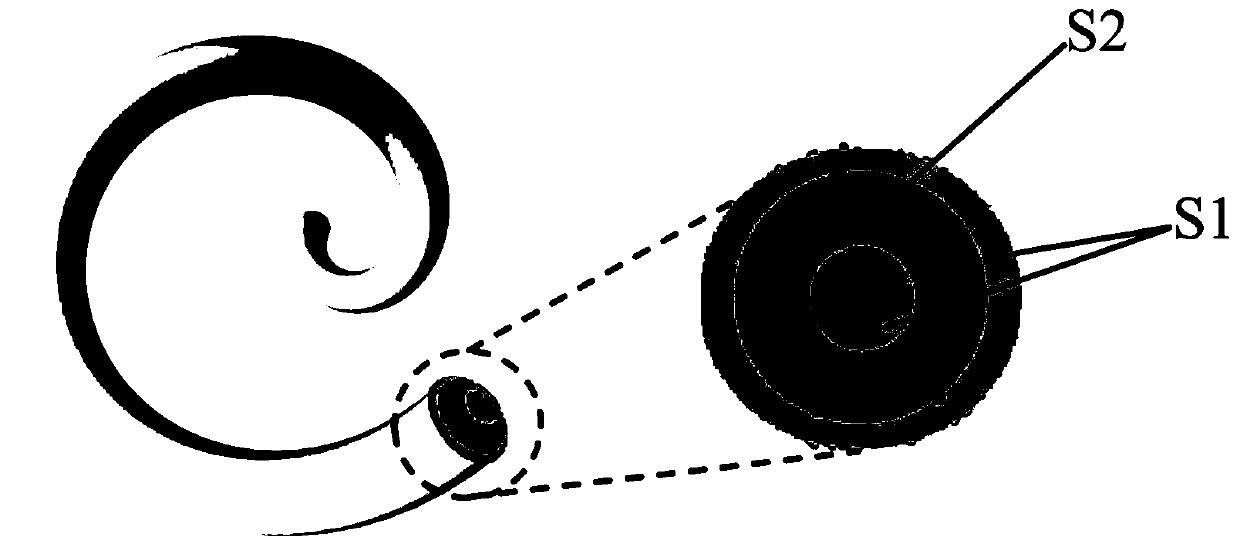

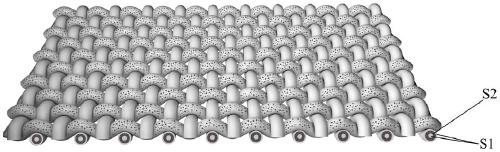

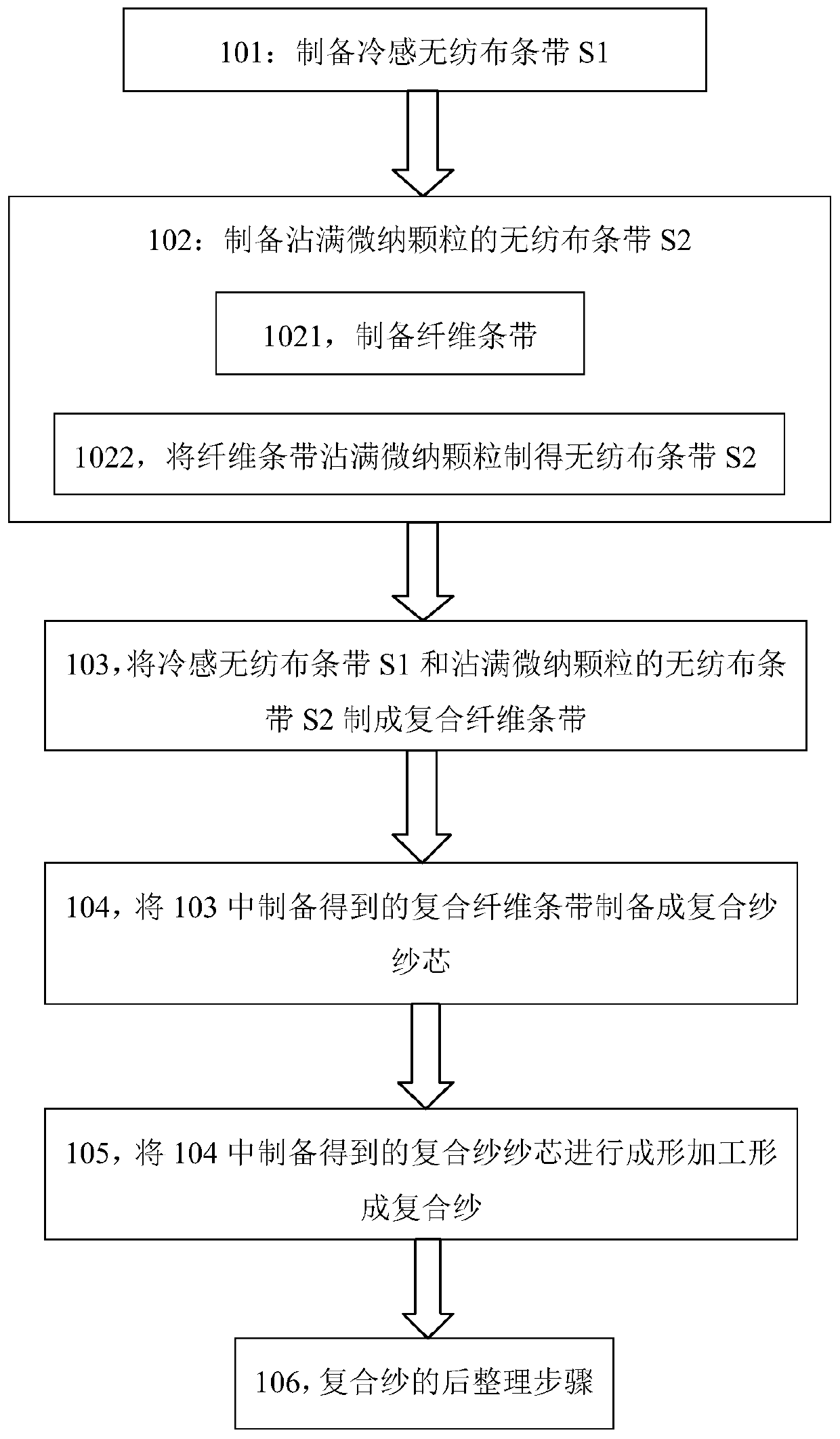

[0037] The invention provides a method for preparing composite yarn with radiation cooling function, such as image 3 As shown, it specifically includes the following steps:

[0038] 101. Preparation of cold-sensing non-woven strips

[0039] Blend the cold-sensing fiber and conventional fiber to form a web, and then prepare the blended fiber into a non-woven surface material through non-woven processes such as needle punching and thermal bonding, and then cut the non-woven fabric surface material to prepare a cool-sensing non-woven fabric strip Tape S1, wound on a bobbin package. Wherein, the cold-sensing fiber is a fiber obtained by blending and spinning micro-nano particles and polymers, and the micro-nano particles therein have a particle size of 0.03 μm-250 μm and a mass concentration of 1%-80%.

[0040] 102. Prepare a non-woven fabric strip S2 covered with micro-nano particles, the non-woven fabric strip S2 covered with micro-nano particles includes a fiber strip, and t...

Embodiment 1

[0065] In this embodiment, the base material of the radiative cooling functional composite yarn prepared by this method is polyethylene (PE) non-woven flexible fiber strips, and the doped inorganic micro-nano particles are TiO 2 , with an average particle size of about 600nm, accounting for 5% of the total volume of the composite yarn with radiative refrigeration function.

[0066] The specific preparation steps are 101, the preparation of the cool non-woven fabric strip S1;

[0067] The doped particle size is 0.03μm-250μm, the mass concentration is 1%-80% TiO 2 The cooling fibers of micro-nano particles are mixed with conventional fibers to form a web, and then the mixed fibers are prepared into non-woven surface materials through non-woven processes such as needle punching and thermal bonding, and then the non-woven surface materials are cut to prepare cold-feeling non-woven fabrics. Spun fabric strip S1 is wound on a bobbin package.

[0068] 102. Preparation of non-woven ...

Embodiment 2

[0083] In this embodiment, the base material of the radiative cooling functional composite yarn is polypropylene (PP) non-woven flexible fiber strip, and the doped inorganic micro-nano particles are TiO 2 , The average particle size is about 600nm, accounting for 5% of the total volume of the composite yarn.

[0084] The preparation method specifically includes:

[0085] 101. Preparation of cool non-woven fabric strip S1; specific steps are the same as in Example 1,

[0086] 102. Preparation of non-woven fabric strip S2 covered with micro-nano particles; including:

[0087] 1021, preparation of fiber strips,

[0088] The polypropylene non-woven flexible surface material with an area density of 5 g / m2 is cut into uniform fiber strips with a linear density of 50 g / km and a width of 10 mm by a cutting machine, and each fiber strip is rolled separately. Winding on the bobbin to form a strip bobbin package.

[0089] 1022, the fiber strips are covered with micro-nano particles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com