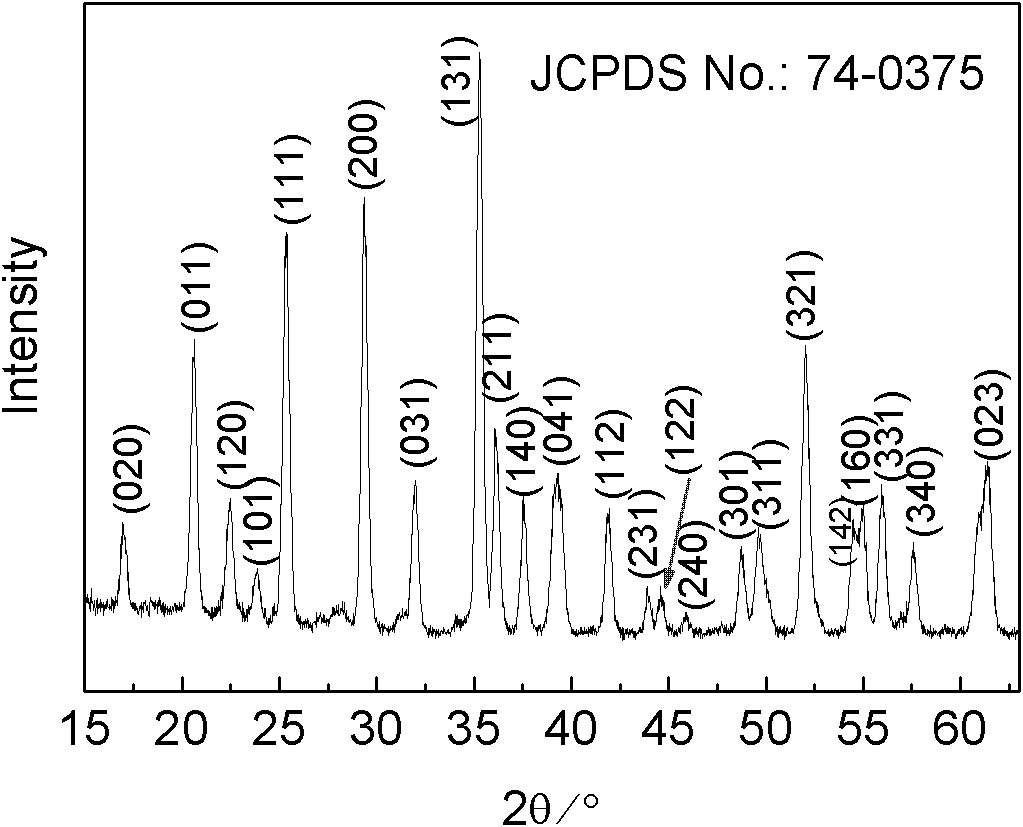

Fiber-ball-shaped lithium manganese phosphate anode material of lithium ion battery and preparation method of fiber-ball-shaped lithium manganese phosphate anode material

A lithium-ion battery and lithium manganese phosphate technology, which is applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of reduced production cost, low volumetric energy density, and complicated preparation process of lithium manganese phosphate, and achieve broad industrial applications Foreground, increased bulk density, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Weigh a certain amount of lithium dihydrogen phosphate and manganese carbonate in proportion, so that the molar ratio of lithium, manganese, and phosphorus is 1:1:1, add it to the mixed solution of deionized water and absolute ethanol, and put it in a stirring ball mill Ball milling while stirring for 8 hours, then, respectively add polyvinyl alcohol with a mass percentage of 10% of the lithium manganese phosphate product as a carbon source, and add polyammonium methacrylate with a mass percentage of 3% of the total mass of raw materials as a dispersant , continue to stir the ball mill for 10 hours, transfer it to the ultrafine mill and ball mill it for 8 hours to obtain a uniform slurry, spray dry the slurry, the inlet temperature is 240°C, the outlet temperature is 65°C, and the fiber spherical precursor is obtained , the fiber spherical precursor was heat-treated in an argon atmosphere at a heating rate of 5°C / min, during the heat treatment, it was fired at a constant...

Embodiment 2

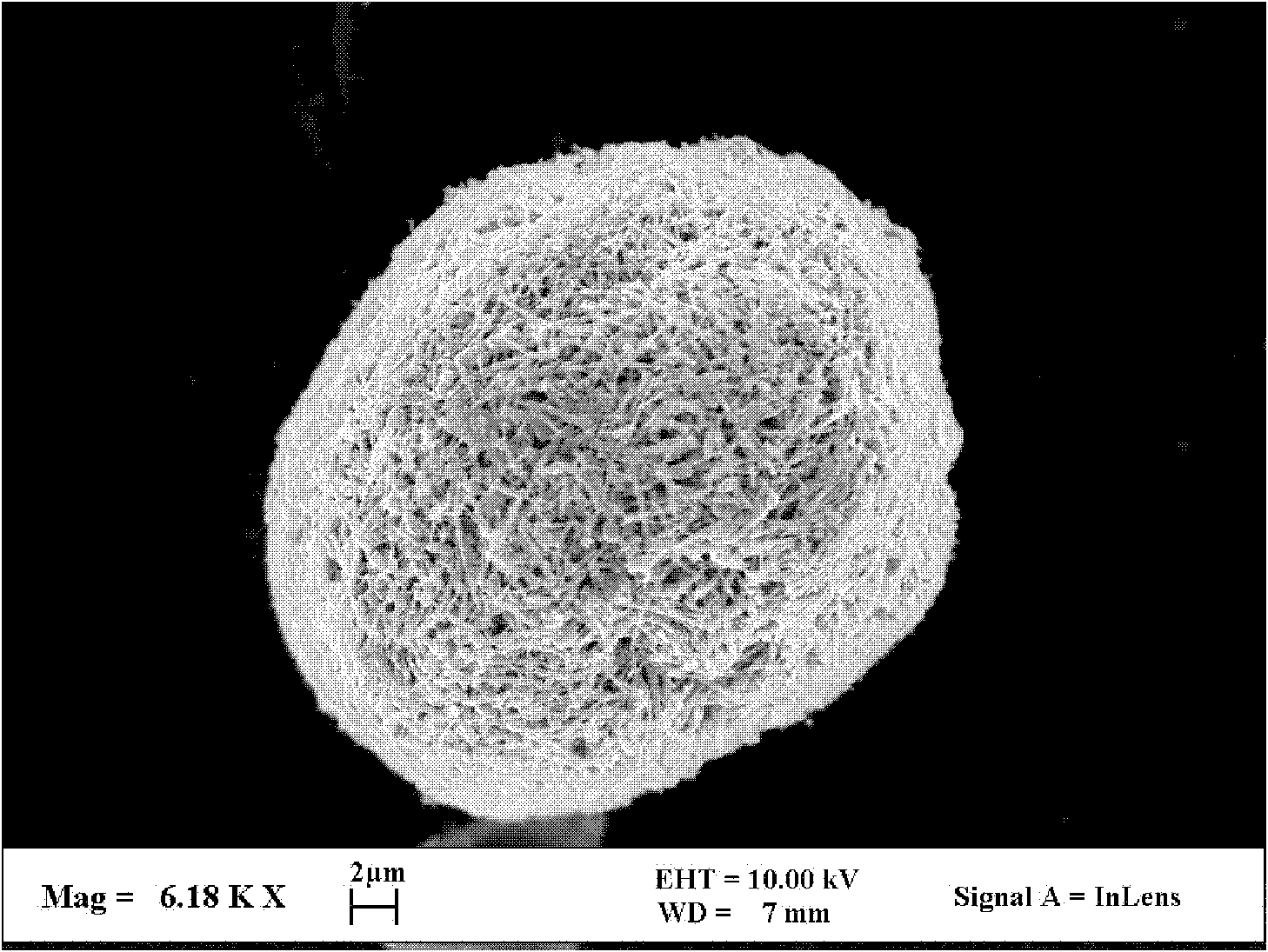

[0059] Weigh a certain amount of lithium dihydrogen phosphate, ammonium dihydrogen phosphate, lithium carbonate and manganese carbonate in proportion, so that the molar ratio of lithium, manganese and phosphorus is 1.05:1:1, add it to deionized water, ethylene glycol and In the mixed solution of water and ethanol, ball mill while stirring in a stirring ball mill for 2 hours, then, add a mixture of 0.1% cellulose and carbon black as a carbon source with a mass percentage of lithium manganese phosphate product, and add a mass percentage of raw material The mixture of polyvinyl alcohol and ammonium citrate with a total mass of 15% is used as a dispersant. After continuing to stir and ball mill for 20 hours, it is transferred to an ultrafine mill for another 1 hour to obtain a uniform slurry. The slurry is spray-dried. The temperature is 150°C, the outlet temperature is 50°C, and the fiber spherical precursor is obtained, and its scanning electron microscope photo is as follows i...

Embodiment 3

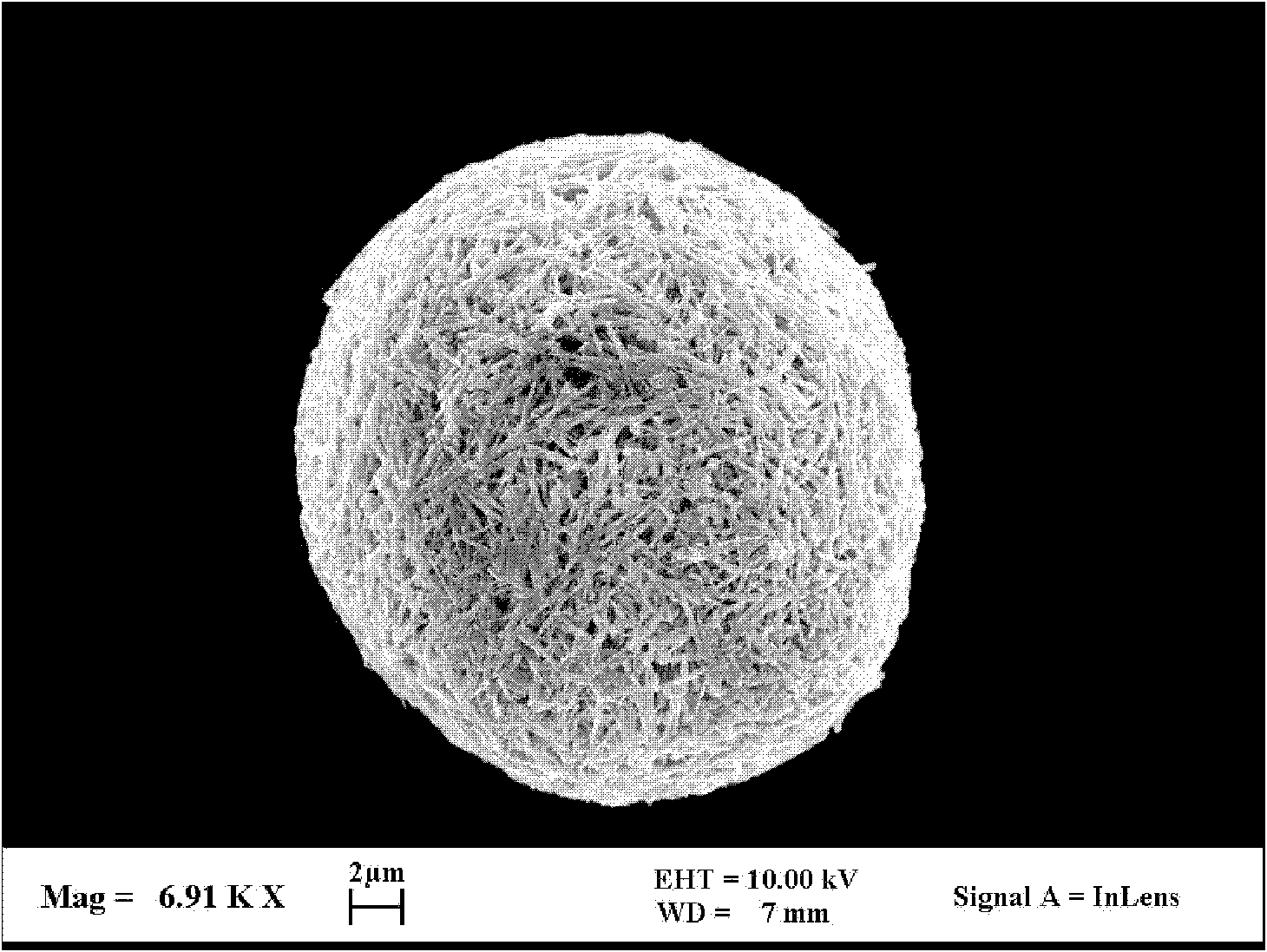

[0061] Weigh a certain amount of lithium dihydrogen phosphate, ammonium phosphate, lithium carbonate, lithium chloride, manganese carbonate and manganese acetate in proportion, so that the molar ratio of lithium, manganese and phosphorus is 1.03:1:1, add it to deionized water , dehydrated alcohol and acetone mixed solution, in the stirring ball mill while stirring ball milling 16 hours, then, add the mixture that mass percent content is lithium manganese phosphate product 20% polyethylene glycol and single crystal rock sugar as carbon source, add The mass percentage content is the mixture of polyvinyl alcohol and ammonium polyacrylate of 5% of the total mass of raw materials as a dispersant, and after continuing to stir and ball mill for 1 hour, transfer it to an ultrafine mill for another 16 hours to obtain a uniform slurry. The material was spray-dried, the inlet temperature was 350° C., and the outlet temperature was 125° C. to obtain a fiber-spherical precursor, whose scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com