Deep sealing type hole sealing device and hole sealing method

A hole-sealing and deep-sealing technology, applied in the directions of sealing/isolation, earthwork drilling, wellbore/well components, etc. The effect of stabilizing problems, reducing operational processes, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

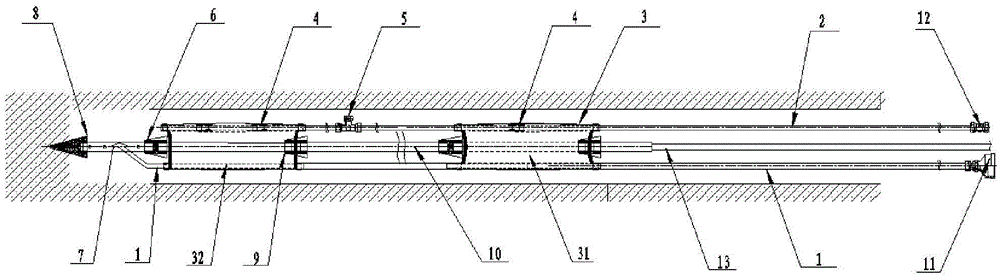

[0044] The present invention will be further described below in conjunction with accompanying drawing:

[0045] A deep-sealing type hole sealing device, comprising an air extraction pipe 1 and a grouting pipe 2 arranged side by side, and the air extraction pipe 1 and the grouting pipe 2 are respectively provided with a sealed bladder 3 at the two ends of the sealing section, close to The orifice position is the orifice pouch 31, and the position near the hole bottom is the hole bottom pouch 32. The pouch 3 is wrapped outside the suction pipe 1 and the grouting pipe 2. The end of the grouting pipe 2 is closed and arranged on the The bottom of the hole bottom bag 32, the grouting pipe 2 is provided with a one-way valve 4 at the inner position of the bag 3, a blast valve 5 is set between the two bags 3, and a flower tube 7 is arranged on the flower tube 7. Notch, flower tube 7 one end is fixed on the outside of the bottom of hole bottom pouch 32, and the other end is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com