Method for preparing coating on surface of hydrophobic insulating layer

A technology of hydrophobic insulating layer and coating film, which is applied to the device for coating liquid on the surface, special surface, pre-treated surface, etc., which can solve the problems that the coating is difficult to form a coating film, difficult to hydrophobic, low hydrophobic insulating layer, etc. , to achieve the effects of strong promotion, low cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Prepare the hydrophobic insulating layer 3.

[0053] First, ultrasonically clean the ITO glass substrate, then drop hydrophobic coating on it, adjust the rotation speed to 1500 r / min, and spin coat to obtain the hydrophobic insulating layer 3, and then put the sample on a hot plate for baking at 95 °C. The time is 5 minutes, and then the sample is placed in an oven from room temperature to 180° C. for 30 minutes. The thickness of the obtained hydrophobic insulating layer 3 is about 800 nm, and the contact angle is about 110°.

[0054] 2) Add film paint 4 on the hydrophobic insulating layer 3 .

[0055] Configure film coating 4, the photoresist SU-8 2000.5 itself is conductive, so it can be directly coated, and its conductivity is measured to be 4.7 μS / cm at a temperature of 22±1°C; then use a pipette to pipette Take 5 μL and drop it on the surface of the hydrophobic insulating layer 3 obtained in step 1.

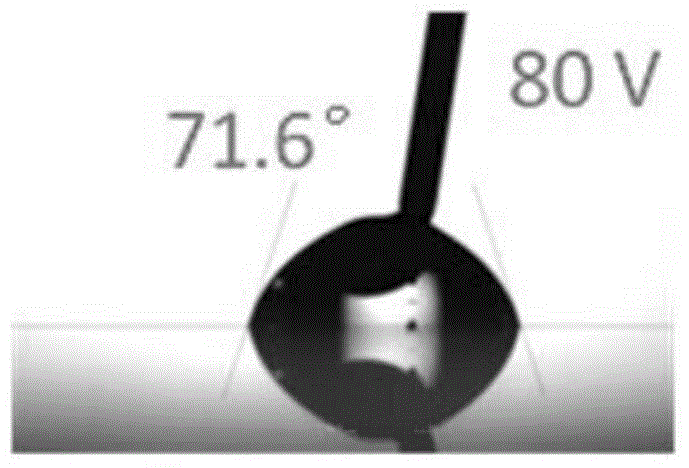

[0056] 3) Perform electrowetting treatment

[0057] In thi...

Embodiment 2

[0062] 1) Prepare the hydrophobic insulating layer 3.

[0063] First, ultrasonically clean the ITO glass substrate, then drop hydrophobic coating on it, adjust the rotation speed to 1500 r / min, and spin coat to obtain the hydrophobic insulating layer 3, and then put the sample on a hot plate for baking at 95 °C. The time is 5 minutes, and then the sample is placed in an oven from room temperature to 180° C. for 30 minutes. The thickness of the obtained hydrophobic insulating layer 3 is about 800 nm, and the contact angle is about 110°.

[0064] 2) Add film paint 4 on the hydrophobic insulating layer 3 .

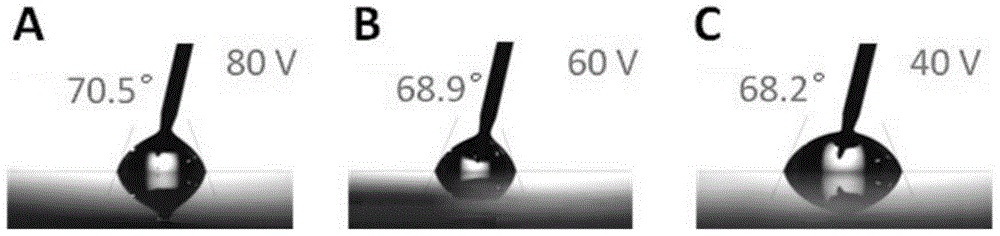

[0065] Configure two-component coating film 4 with different conductivity, photoresist SU-8 3005 and ionic liquid [BMIM] BF 4 Mix according to different mass ratios of 20:1, 10:1, and 5:1 to obtain two different coating film coatings 4, and measure the corresponding electrical conductivity under the environment of 22±1°C. 32.3 μS / cm, 56.4 μS / cm, 113.8 μS / cm; then use a pipe...

Embodiment 3

[0074] 1) Prepare the hydrophobic insulating layer 3.

[0075] First, ultrasonically clean the ITO glass substrate, then drop hydrophobic paint on it, adjust the rotation speed to 1500r / min, spin coat to obtain a hydrophobic insulating layer 3, and then put the sample on a hot plate for baking at a temperature of 95°C for a period of time After 5 minutes, the sample was placed in an oven from room temperature to 180°C for 30 minutes. The resulting hydrophobic insulating layer 3 had a thickness of about 800 nm and a contact angle of about 110°.

[0076] 2) Add film paint 4 on the hydrophobic insulating layer 3 .

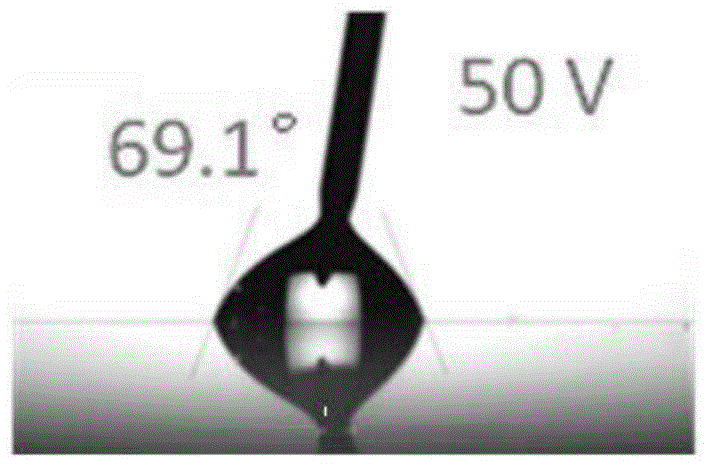

[0077] Configure the film coating 4 with three components mixed, the photoresist SU-8 3050 and the ionic liquid [BMIM] BF 4 、[BMIM] PF 6 Mix according to the mass ratio of 10:1:1 to obtain three-component film paint 4, and measure its conductivity at 22±1°C to obtain a conductivity of 97.4 μS / cm; then use a pipette to pipette 5 μL was dropped onto the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com