Preparation method of magnetic-response wood/Fe3O4 composite material

A composite material and magnetic response technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of complex process, poor bonding between magnetic substances and wood substrate, long preparation period, etc., to achieve firm bonding, tight bonding strength, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

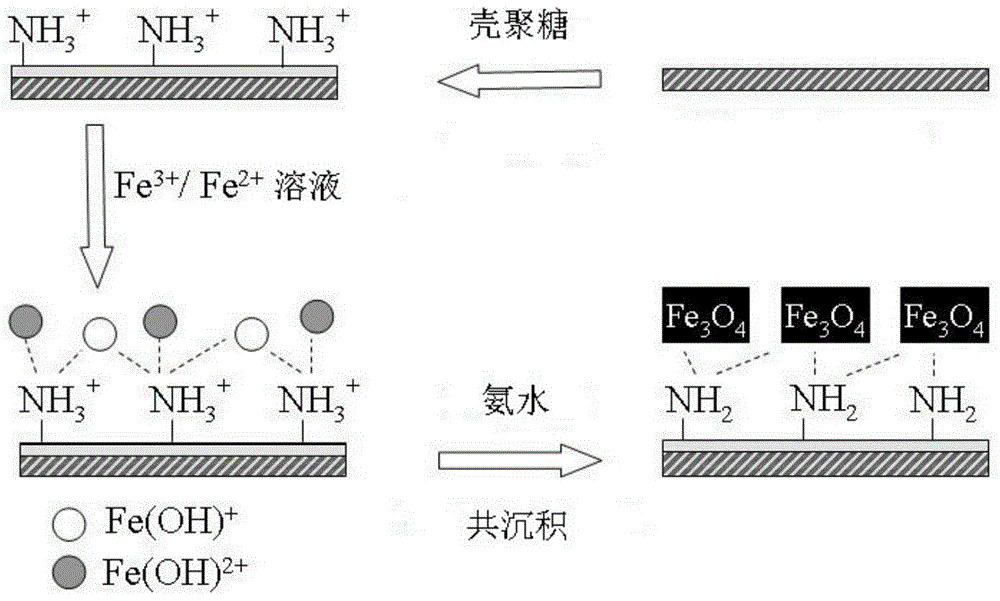

[0030] Specific implementation mode 1: This implementation mode is a magnetic response wood / Fe 3 o 4 The preparation method of the composite material is specifically completed according to the following steps:

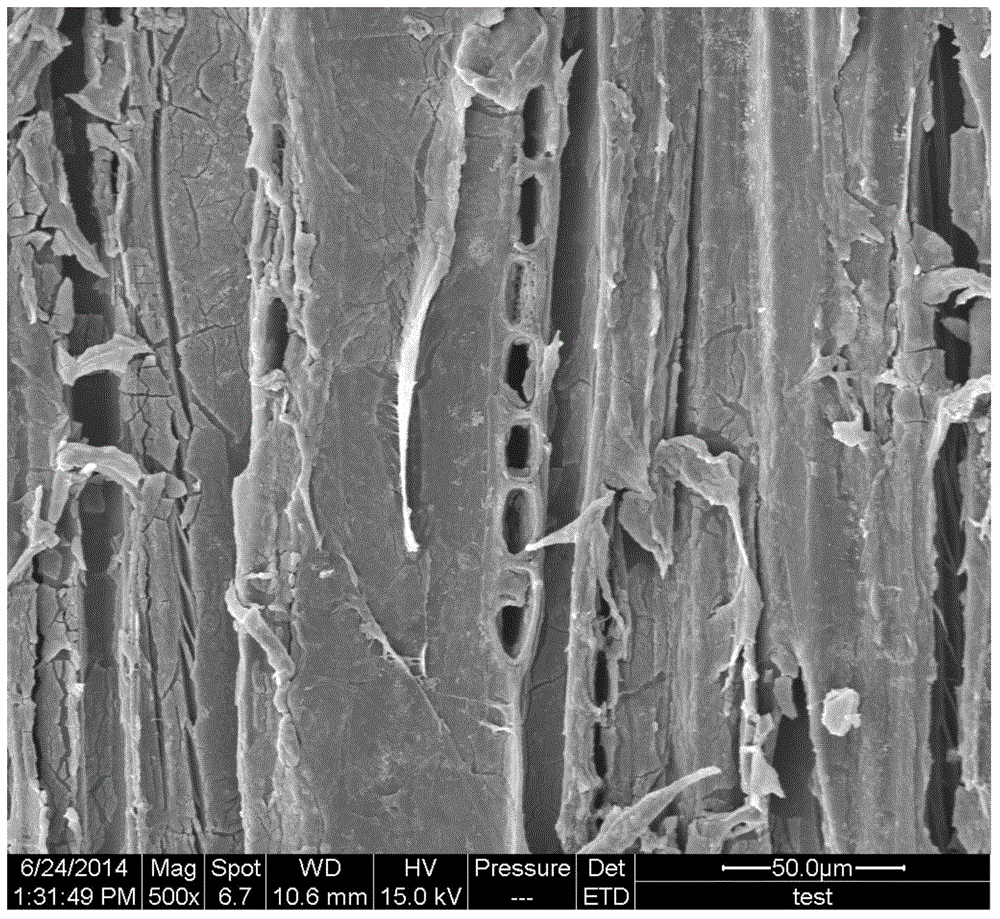

[0031] 1. Ultrasonic treatment: ultrasonically treat the wood substrate in distilled water, ethanol and acetone for 20-25 minutes respectively, and then dry it naturally at room temperature for 24-48 hours to obtain the wood substrate after ultrasonic treatment;

[0032] 2. Carry out chitosan modification: soak the wood substrate after ultrasonic treatment in 0.2%~1.0% chitosan solution for 10min~30min, dry at 30℃~40℃ for 5min~15min to obtain chitosan modification After the wood substrate;

[0033] The surface area of the wooden substrate described in step 2 and the volume ratio of the chitosan solution of 0.2%~1.0% are (0.1cm 2 ~1.0cm 2 ): 1mL;

[0034] 3. Loading iron salt solution: immerse the chitosan-modified wood matrix into the iron salt solution for 10mi...

specific Embodiment approach 2

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent in the 0.2%-1.0% chitosan solution described in step 2 is 0.5wt%-2.5wt% acetic acid. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the iron salt solution described in step three is FeCl 2 solution and FeCl 3 The mixed liquor of the solution; FeCl in the described iron salt solution 2 The concentration of the solution is 0.0375mol / L~0.9mol / L, FeCl in the iron salt solution 3 The concentration of the solution is 0.0625mol / L-1.5mol / L. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com