Comprehensive recovery method for tin-stripping waste liquid

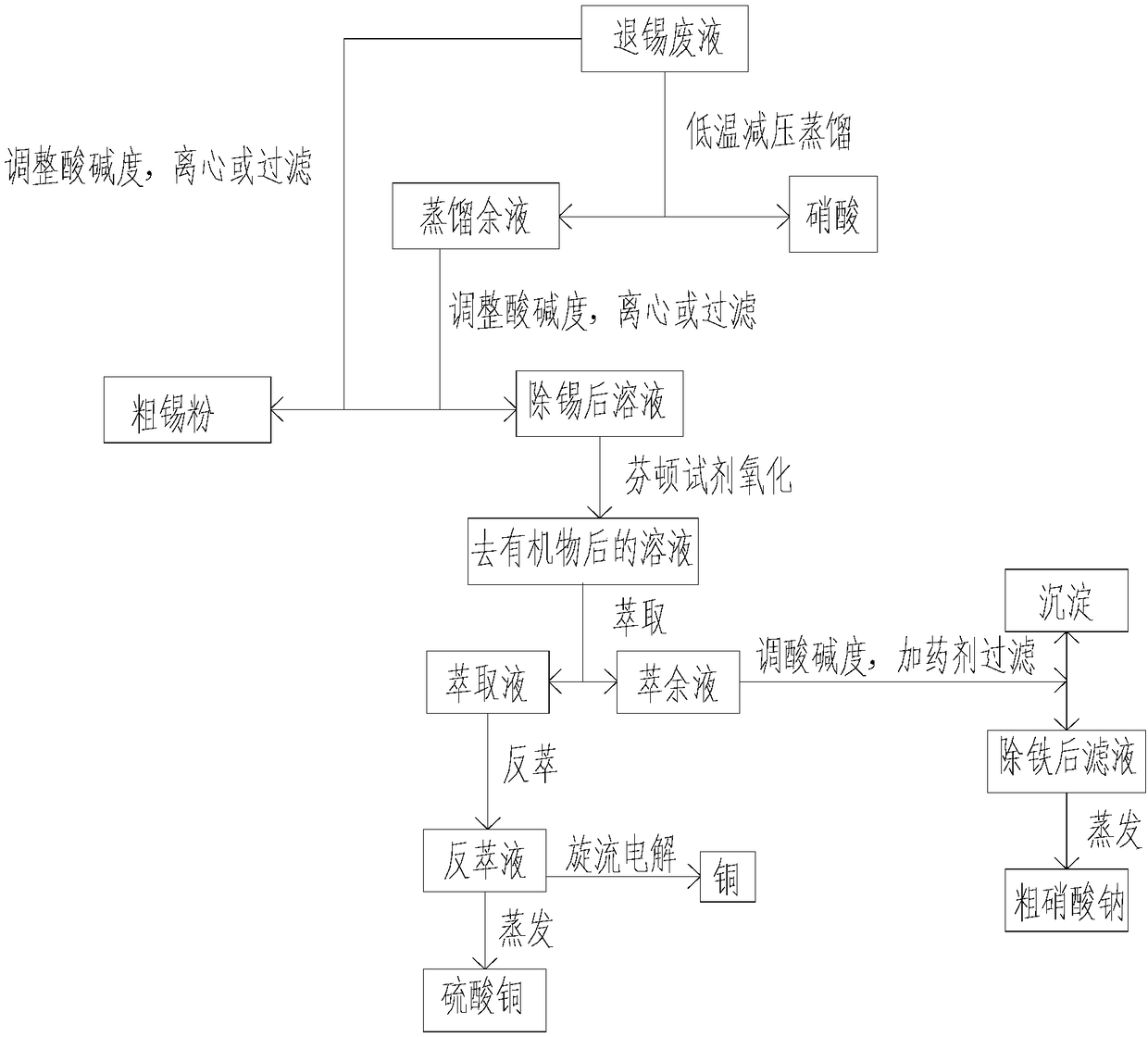

A recycling method and tin stripping technology, applied in the direction of improving process efficiency, can solve the problems of secondary pollution, excessive tin stripping waste liquid, insufficient recovery of components, low comprehensive recovery rate, etc., so as to achieve no secondary pollution and good practicality. Value and comprehensive benefits, the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Element

[0025] Treatment steps: 1) Pass the tin stripping waste liquid into the distillation device for vacuum distillation operation, the temperature is controlled at about 80°C, the pressure is kept at 0.03-0.04MPa, and the distillation condensate is collected as nitric acid; 2) The distillation residue The liquid is naturally cooled at room temperature. When the temperature reaches below 30°C, adjust the pH of the distilled residual liquid to about 1.5 with caustic soda, add 0.5‰ PAM for natural precipitation, filter and separate the solid substance, which is the tin compound, and obtain the tin removal solution. Tin compounds can be sold as coarse tin powder; 3) Measure the COD of the solution after tin removal, continue to adjust the pH of the solution after tin removal to 3-4 with caustic soda, then add hydrogen peroxide to the solution, and the dosage is 1.1 times the COD of the solution , at the same time add a little ferrous iron and stir for about 2...

Embodiment 2

[0027] A professional treatment enterprise of printed circuit board waste liquid in Jiangsu, the main components of its tin stripping waste liquid are nitric acid 10.2% (mass percentage), tin 85g / L, copper 2.3g / L, iron 3.7g / L, lead 25mg / L L. Treatment steps: 1) Directly use caustic soda to adjust the pH of the tin-removing waste liquid to about 1, stir and add 0.5‰ PAM for reaction, filter and separate the solid substance after natural precipitation, which is the tin compound, and obtain the tin removal solution. The tin compound can be Sold as coarse tin powder; 2) Measure the COD of the solution after tin removal, continue to adjust the pH of the filtrate to 3-4 with caustic soda, then add hydrogen peroxide to the solution, the dosage is 1.1 times the COD of the solution, and add a little ferrous iron at the same time 3) Extract the organic-free solution obtained after the reaction with Lix984, separate the extract and raffinate, back-extract the extract with sulfuric acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com