Method and device for recovering sensible heat of blast furnace slag

A technology for recovering sensible heat and blast furnace slag, which is applied in the direction of recycling technology, plastic recycling, and improvement of process efficiency. The effect of blast furnace slag sensible heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

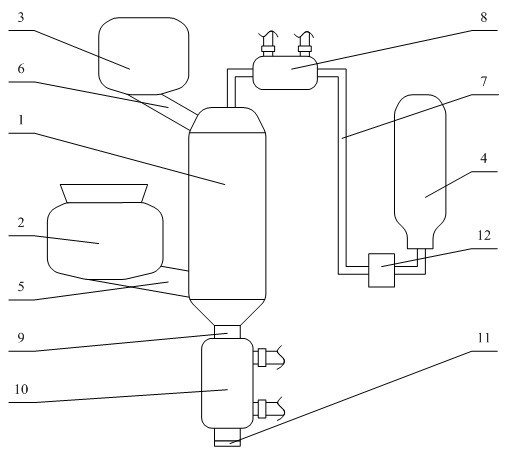

[0044] In order to implement the above method for recycling sensible heat of blast furnace slag, this embodiment adopts a device for recycling sensible heat of blast furnace slag. The structure of the device is as follows: image 3 As shown, it includes a pyrolysis furnace 1, a dry granulation device 2, a powder container 3 and a gas collection container 4; the discharge port of the dry granulation device 1 is connected to the lower part of the pyrolysis furnace 1 through a blast furnace slag channel 5; the powder The container 4 is used to store the printed circuit board substrate powder, and its bottom is provided with an openable powder outlet, and the powder outlet is connected to the upper part or top of the pyrolysis furnace 1 through the powder channel 6; the top of the pyrolysis furnace 1 is also provided with a The air flow passage 7 of the gas collection container 4, the air flow passage 7 is provided with a first heat exchanger 8; the bottom of the pyrolysis furnace ...

Embodiment 2

[0052] Using the blast furnace slag sensible heat recycling device described in Example 1 and the operation process of blast furnace slag sensible heat recycling, this embodiment has carried out four groups of blast furnace slag sensible heat recovery experiments in addition to study the main factors that have an impact on the method of the present invention. factor. In these four groups of blast furnace slag sensible heat recovery experiments, the control temperature T of the blast furnace slag particles sent out by the dry granulation device 渣0 , The mass of blast furnace slag particles added to the pyrolysis furnace M 高炉渣 and PCB substrate powder M PCB The control amount of the parameters is different, and the gas product mass M 气 and blast furnace slag sensible heat recovery δ to reflect the impact of parameter control changes. The parameter control quantities and experimental calculation results of the four groups of blast furnace slag sensible heat recovery experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com