Automatic electric quantity calibrating system and automatic electric quantity calibrating method

An automatic calibration and calibration system technology, applied in the field of electromagnetic measurement, can solve the problems of failure to realize the modularization, generalization and serialization of measurement guarantee equipment, the inability to allocate measurement resources on demand, and the lack of unified standards and design frameworks. , to achieve the effect of improving the efficiency of measurement and calibration, solving the redundant waste of multiple resources, and saving calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention specifically relates to an automatic calibration system for electrical quantities and a calibration method thereof, which can satisfy the automatic calibration work of the automatic test system under laboratory and implementation conditions. To solve the problem of automatic calibration, it is necessary to provide high-precision signal excitation for the measured object, and accurately realize the control, identification and sampling of the electrical parameters of the measured system, and realize the automatic processing of the calibration elements.

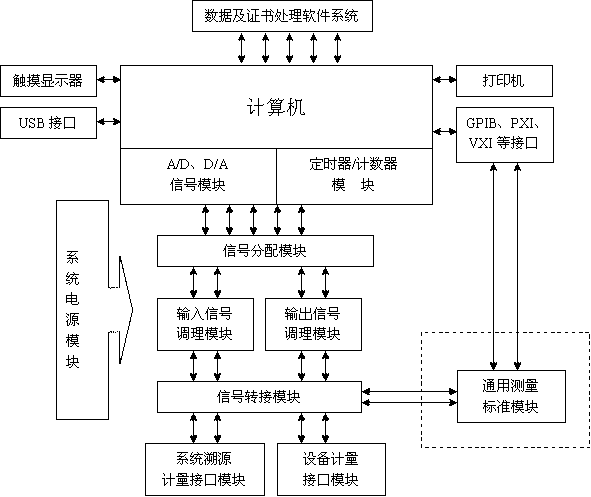

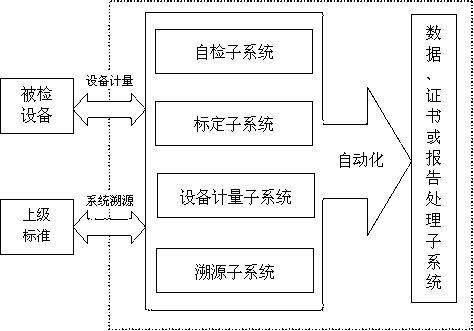

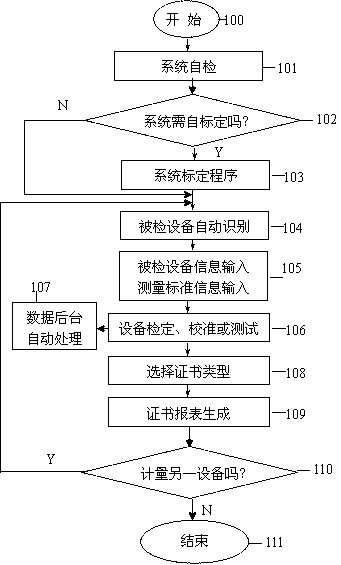

[0043] attached figure 1It is the principle framework of the electrical quantity automatic calibration device, mainly composed of computer, AD / DA module, timer / counter module, signal distribution module, signal conditioning module, signal transfer module, system traceability measurement interface module, equipment measurement interface module, power supply module It is composed of a common measurement standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com