Preparation device and preparation method for electronic ink microcapsule

A technology of electronic ink and preparation equipment, which is applied in the direction of microcapsule preparation, microsphere preparation, ink, etc., can solve the problems of uneven particle size of microcapsules, low manufacturing efficiency, and poor product repeatability, and achieve uniform particle size , low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

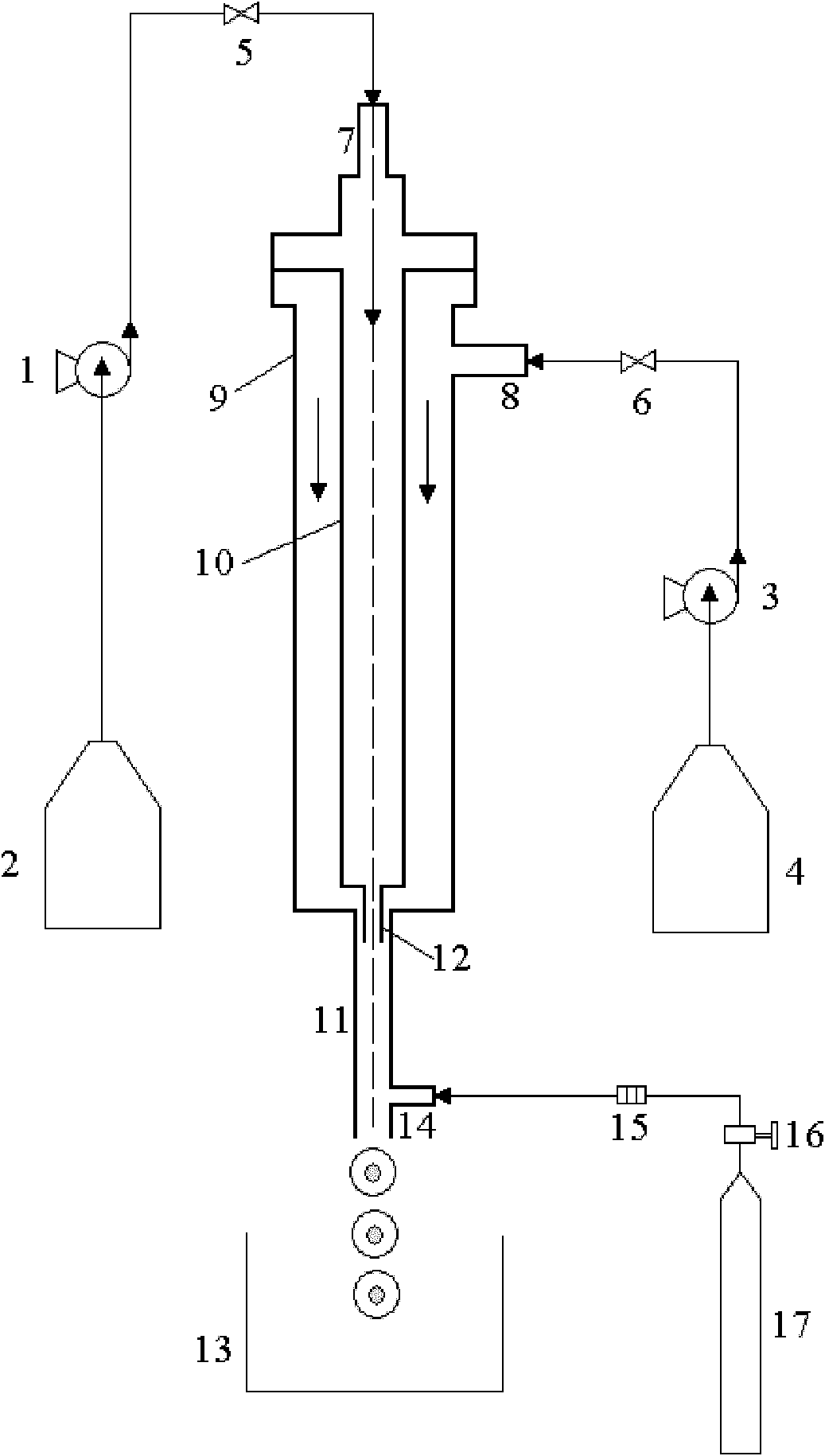

Method used

Image

Examples

Embodiment 1

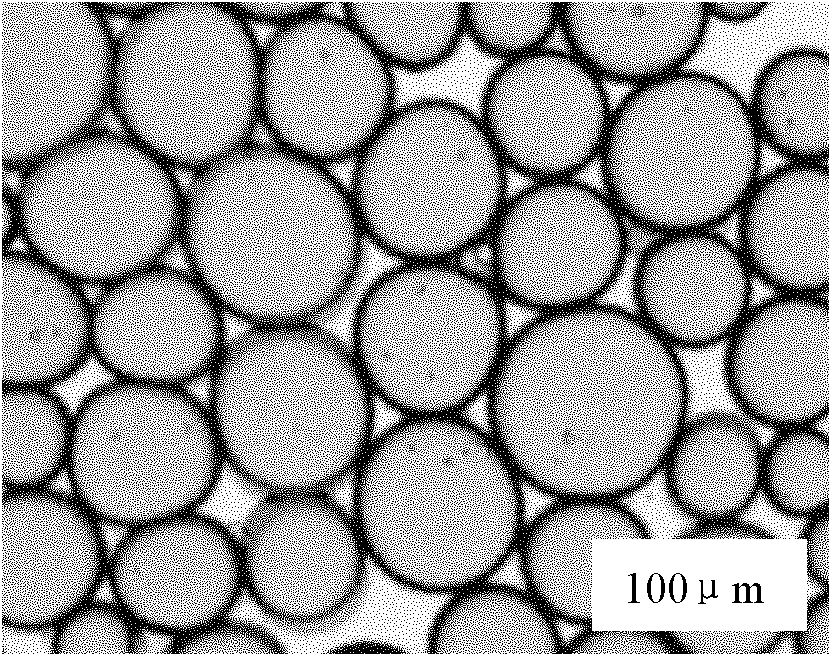

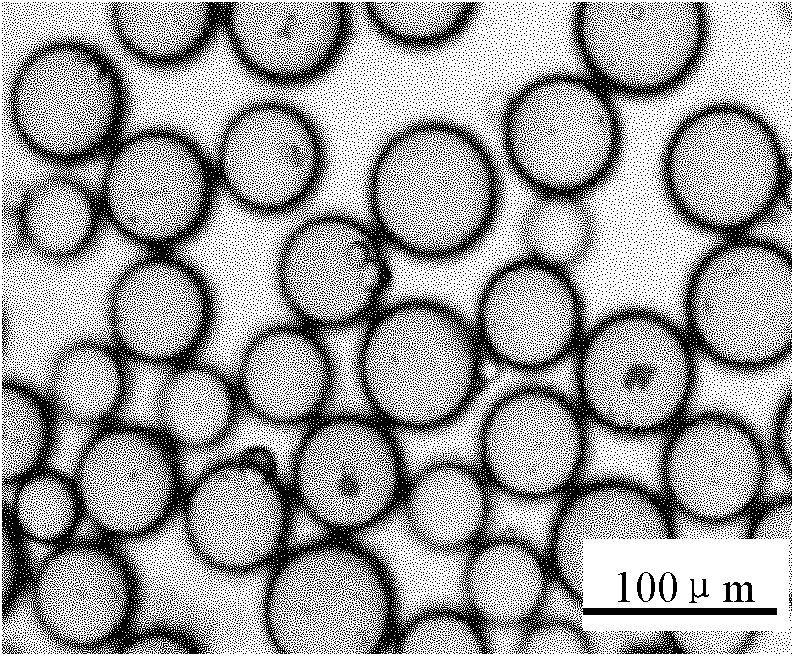

[0034] Dissolve 3 g of toluidine red in 500 mL of concentrated sulfuric acid, and stir to obtain a toluidine red solution. Dissolve 100mL of alkyl hydroxamic acid in 10L of water, slowly add the toluidine red solution dropwise into the aqueous solution, react for 20 minutes, add carbon tetrachloride, react for 10 minutes under stirring at 20°C, then let stand to separate layers, and remove the lower layer, namely A red electrophoretic display solution was obtained. The capsule wall material is prepared from gelatin and carboxymethyl cellulose, respectively prepare gelatin aqueous solution and carboxymethyl cellulose aqueous solution with a concentration of 2.5%, take 5L of gelatin aqueous solution, stir at 600r / min at 40°C, and heat to the preset temperature Finally, add 1.3g / L SDS, stir for 30min, then add 1L1 concentration of 2.5% carboxymethylcellulose aqueous solution, stir for 30min, add appropriate amount of acetic acid, adjust the pH value to 3.5-3.8. The red electroph...

Embodiment 2

[0036] Dissolve 5g of toluidine red in 1L of tetrahydrofuran; measure 100mL of Span-80 and add it to 20L of deionized water. Under the condition of stirring at room temperature, add the toluidine red-tetrahydrofuran solution dropwise into the aqueous solution to react for 15 minutes, then add 800 mL of tetrachloroethylene and 250 mL of cyclohexane, continue stirring for 10 minutes, then let stand for 10 minutes, and remove the lower layer. Add 5g of dispersant UV681, and magnetically stir for 30min at room temperature to obtain a red electrophoretic display solution. The capsule wall material is water-based polyurethane JF4015, with a solid content of 33±1%. Add 0.5% curing agent JF9001 under stirring conditions, and stir for 10-15 minutes until the mixture is uniform. Pass the red electrophoretic display solution and the cyst wall solution into the inner and outer tubes respectively, control the flow rate of the red electrophoretic solution to 1L / hr, and the flow rate of the ...

Embodiment 3

[0038] Dissolve 4g of red powder in 1L of dimethyl sulfoxide; measure 100mL of alkylhydroxamic acid and add it to 200mL of ethanol. After it is completely dissolved, add it into 20L of deionized water. Under room temperature and stirring conditions, the red powder-dimethyl sulfoxide solution was added dropwise into water to react for 15 minutes, then 1L of tetrachlorethylene and 300mL of isopropanol were added, and after stirring, the layers were separated, the lower layer was removed, and 3.5g of CH- 6 Stir to obtain a red electrophoretic display solution. The capsule wall material is water-based transparent polyurethane JF4015, with a solid content of 33±1%. Add about 0.5% curing agent JF9001 under stirring conditions, and stir for 10-15 minutes until the mixture is uniform. The red electrophoretic display solution and the capsule wall solution are passed into the inner and outer tubes respectively, and the feed flow rate of the red electrophoretic display liquid is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com