Tempering type high-strength steel plate for low-temperature container and production method for tempering type high-strength steel plate

A low-temperature container and production method technology, applied in the field of metallurgy, can solve problems such as high cost, poor steel plate performance, and unsatisfactory use effect, and achieve low production cost, good comprehensive mechanical properties and welding performance, and strong market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

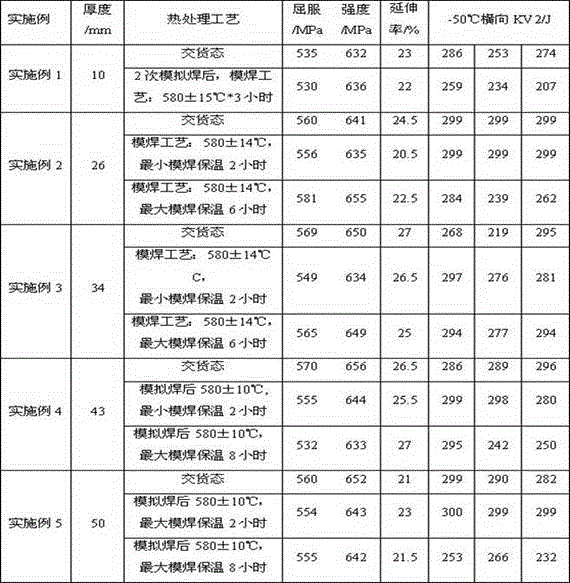

Embodiment 1

[0029] The thickness of the tempered high-strength steel plate for low-temperature containers in this embodiment is 10 mm, and it is formed by melting the following components by mass percentage:

[0030] C: 0.05%, Si: 0.20%, Mn: 1.50%, P: 0.010%, S: 0.005%, Alt: 0.020%, Ni: 0.30%, Mo: 0.15%, Nb: 0.016%, the balance is Fe and Trace unavoidable impurities. Crack sensitivity index Pcm: 0.158%, carbon equivalent Ceq: 0.378%.

[0031] The production method of the quenched and tempered high-strength low-temperature container steel plate of the present embodiment, the specific steps are:

[0032] (1) Smelting: The molten steel containing the above-mentioned chemical components in each weight percentage is first smelted in a converter, and then sent to an LF refining furnace for refining, fed with an Al wire of 200m, and the refining process ensures that the refining slag is white to ensure the deoxidation effect; the refining is completed Vacuum treatment in the VD furnace of the ...

Embodiment 2

[0041] The quenched and tempered steel plate for high-strength low-temperature containers in this embodiment has a thickness of 26 mm, and is formed by melting the following components by mass percentage:

[0042] C: 0.06%, Si: 0.24%, Mn: 1.60%, P: 0.008%, S: 0.003%, Alt: 0.034%, Ni: 0.33%, Mo: 0.16%, Nb: 0.025%, the balance is Fe and Trace unavoidable impurities. Crack sensitivity index Pcm: 0.163%, carbon equivalent Ceq: 0.397%.

[0043] The production method of the quenched and tempered high-strength low-temperature container steel plate of the present embodiment, the specific steps are:

[0044] (1) Smelting: The molten steel containing the above-mentioned chemical components in each weight percentage is first smelted in a converter, and then sent to an LF refining furnace for refining, fed with an Al wire of 260m, and the refining process ensures that the refining slag is white to ensure the deoxidation effect; the refining is completed Vacuum treatment in the VD furnac...

Embodiment 3

[0053] The quenched and tempered steel plate for high-strength low-temperature containers in this embodiment has a thickness of 34 mm, and is formed by melting the following components by mass percentage:

[0054] C: 0.08%, Si: 0.45%, Mn: 1.51%, P: 0.007%, S: 0.004%, Alt: 0.050%, Ni: 0.45%, Mo: 0.24%, Nb: 0.025%, the balance is Fe and Trace unavoidable impurities. Crack sensitivity index Pcm: 0.187%, carbon equivalent Ceq: 0.428%.

[0055] The production method of the quenched and tempered high-strength low-temperature container steel plate of the present embodiment, the specific steps are:

[0056] (1) Smelting: The molten steel containing the above-mentioned chemical components in each weight percentage is first smelted in a converter, and then sent to an LF refining furnace for refining, fed with an Al wire of 300m, and the refining process ensures that the refining slag is white to ensure the deoxidation effect; the refining is completed Vacuum treatment in the VD furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com