X90 pipeline steel wide and thick plate and production method thereof

A production method and technology for wide and thick plates are applied in the field of low-carbon microalloyed steel, which can solve the problems of increased construction cost and increased weight of steel pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

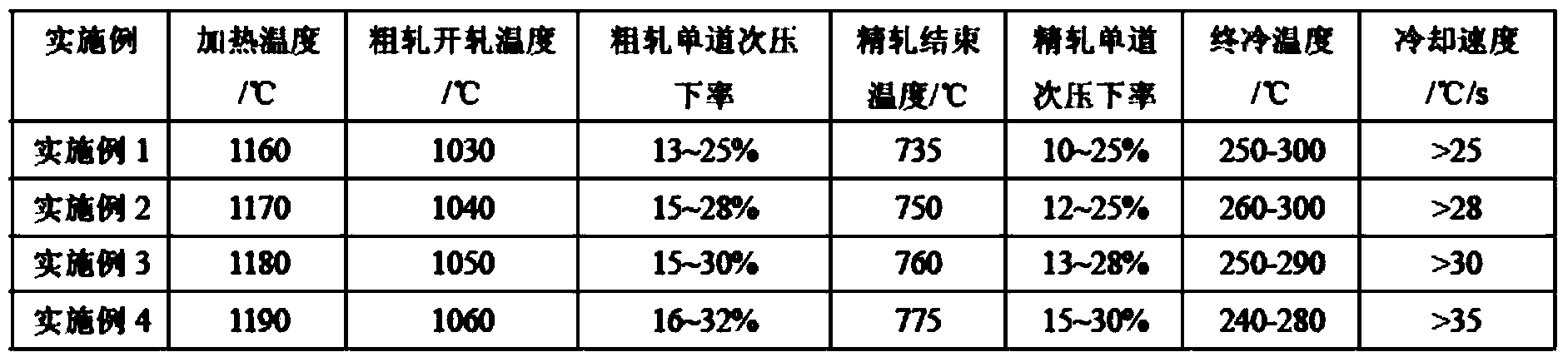

[0030] According to the economical X90 pipeline steel wide and thick plate and its manufacturing method of the present invention, it is smelted on a 100-ton converter, cast into a continuous casting slab of 300mm×2400mm×2700mm, and rolled on a 4300mm wide and thick plate production line. The chemical composition is shown in Table 1, the process system is shown in Table 2, and the mechanical properties of the steel plate are shown in Table 3.

[0031] Table 1 Chemical composition wt% of steel plate

[0032] Example

O

Si

mn

P

S

Al

Nb

Ni

Ti

Cr

Cu

Mo

N

H

Example 1

0.045

0.25

1.80

0.011

0.0013

0.034

0.078

0.175

0.014

0.21

0.20

0.15

0.004

0.0001

Example 2

0.056

0.24

1.79

0.010

0.0008

0.036

0.063

0.175

0.014

0.19

0.21

0.12

0.003

0.0001

Example 3

0.060

0.22

1.75

0.009

0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com