Preparation method of high-strength titanium alloy wire

A titanium alloy wire and high-strength technology, applied in the field of material science, can solve problems such as the inability to fully meet the requirements of load-carrying capacity, the difficulty of ensuring surface integrity, and the easy formation of burrs on the thread, achieving high plasticity and toughness, shortening the cycle, and simplifying the process. The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

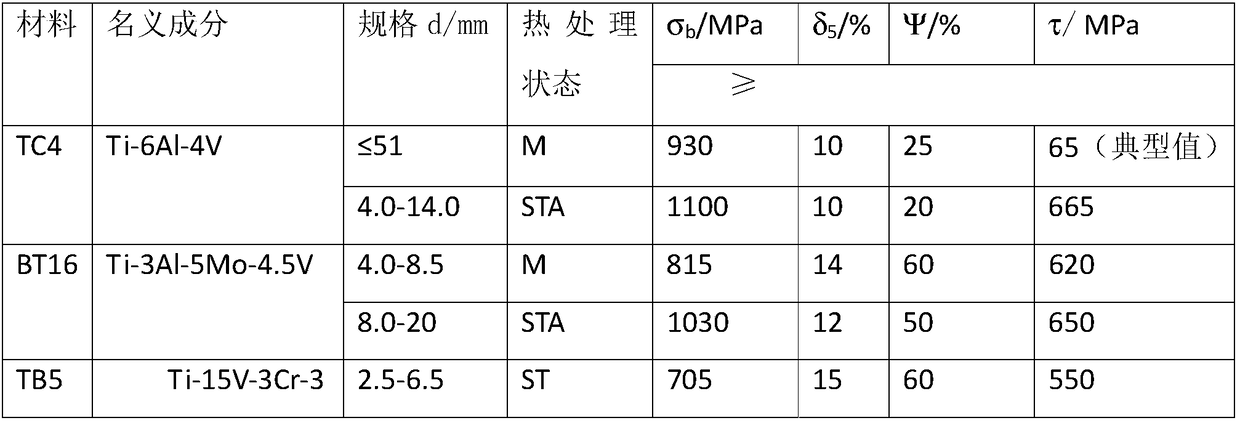

[0028] A φ230mm ingot was prepared by three vacuum consumable smelting processes. The composition of the ingot is shown in Table 2. The measured phase transition point T β It is 868°C.

[0029] Table 2 Analysis results of the upper, middle and lower chemical components of the alloy

[0030]

Al

V

Mo

Nb

Fe

C

O

N

H

superior

6.52

5.97

3.9

1.99

1.08

0.01

0.06

0.007

0.0005

middle

6.64

5.93

3.95

2.06

0.99

0.01

0.07

0.008

0.0005

Down

6.68

6.01

3.8

1.93

0.99

0.01

0.10

0.006

0.0005

[0031] The ingot was heated and kept at 1150°C, and the holding time was calculated as 140 minutes based on 0.6min / mm. The ingot was subjected to two upsetting and two drawing, and the drawing was lengthened to Φ220mm±10mm, chamfered, rounded, and air-cooled. Heat the forged bar at 1000°C and keep it warm. The holding time is calculated as 130 minutes according...

Embodiment 2

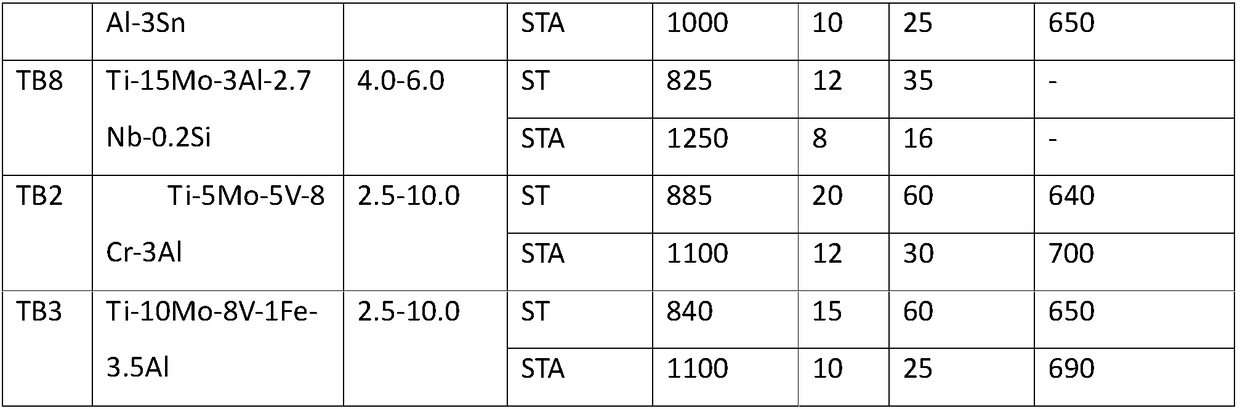

[0035] A φ360mm ingot was prepared by three vacuum consumable melting processes. The composition of the ingot is shown in Table 4. The measured phase transition point T β It is 863°C.

[0036] Table 4 Analysis results of upper, middle and lower chemical composition of the alloy

[0037]

[0038]

[0039] The ingot was heated and kept at 1150°C, and the holding time was calculated as 290 minutes according to 0.8min / mm. The ingot was subjected to two upsetting and two drawing, and the drawing was lengthened to Φ270mm±10mm, chamfered, rounded, and air-cooled. Heat the forged rod at 1000°C and keep it warm. The heat preservation time is calculated as 220 minutes according to 0.8min / mm. The forged rod is subjected to two upsetting and two drawing operations until it is drawn to Φ190mm±10mm, chamfered, rounded, and air-cooled. Peel the forged bar, remove surface forging defects, and pour R20 rounded corners. Put the peeling forging rod on the T β Heat and hold at -43°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com