High-strength martensite stainless steel plate and production method thereof

A technology of martensitic stainless steel and production method, which is applied in high-strength martensitic stainless steel plate and its production field, can solve the problems of unguaranteed plate shape, difficult production, unstable performance, etc., and achieve good appearance quality and surface quality Good, stable performance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

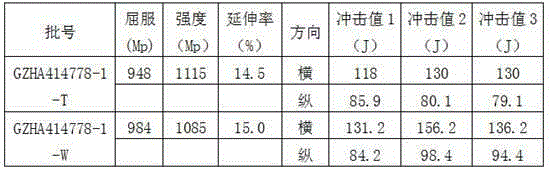

Examples

Embodiment 1

[0036] Embodiment 1: The high-strength martensitic stainless steel plate adopts the following composition ratio and production steps.

[0037] The thickness of the martensitic stainless steel plate is 43mm, and the mass percentage of chemical composition is: C0.020%, Si0.50%, Mn0.50%, P0.015%, S0.005%, Ni4.50%, Cr15 .00%, Mo0.80%, H0.00013%, N0.0260%, the balance is Fe and unavoidable impurities.

[0038] The production steps of this martensitic stainless steel plate are as follows: (1) Billet opening process: clean the surface before loading the steel, lower the furnace temperature to 280°C and load it, and then stew the steel for 5 hours; , the heating rate is 8°C / h; between 400°C and 650°C, the heating rate is 18°C / h; between 650°C and 900°C, the heating rate is 25°C / h; the maximum heating temperature is 1180°C. After 96 hours of heating, billet rolling is carried out. The thickness of the billet is 220mm. After the billet is opened, when the temperature drops to 650°C, p...

Embodiment 2

[0045] Embodiment 2: The high-strength martensitic stainless steel plate adopts the following composition ratio and production steps.

[0046] The thickness of this martensitic stainless steel plate is 44mm, and the mass percentage of chemical composition is: C0.025%, Si0.95%, Mn0.61%, P0.020%, S0.006%, Ni4.70%, Cr15 .88%, Mo0.91%, H0.00020%, N0.0350%, the balance is Fe and unavoidable impurities.

[0047] The production steps of this martensitic stainless steel plate are as follows: (1) Steel ingot billeting process: clean the surface of the steel ingot before loading the steel, lower the furnace temperature to 250°C and load it, and then stew the steel for 5.5 hours; use low-speed burning steel, 400 Below ℃, the heating rate is 9°C / h; between 400°C and 650°C, the heating rate is 19°C / h; between 650°C and 900°C, the heating rate is 25°C / h, and the maximum heating temperature is 1180°C. After 92 hours of heating, the steel ingot is rolled at a uniform temperature, and the bla...

Embodiment 3

[0054] Embodiment 3: The high-strength martensitic stainless steel plate adopts the following composition ratio and production steps.

[0055] The thickness of the martensitic stainless steel plate is 44mm, and the mass percentage of chemical composition is: C0.045%, Si0.85%, Mn0.88%, P0.019%, S0.009%, Ni5.10%, Cr15 .88%, Mo0.91%, H0.00013%, N0.0350%, the balance is Fe and unavoidable impurities.

[0056] The production steps of this martensitic stainless steel plate are as follows: (1) Steel ingot billeting process: clean the surface before loading steel, lower the furnace temperature to 260°C to assemble steel, and then stew steel for 5.0h; adopt low-speed burning steel, 400°C Below, the heating rate is 9°C / h; between 400°C and 650°C, the heating rate is 19°C / h; between 650°C and 900°C, the heating rate is 26°C / h, and the maximum heating temperature is 1180°C. After 94 hours of heating, the steel ingot is rolled at a uniform temperature, and the billet opening process adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com