Self-lubricating wear-resistant composite coating for titanium alloy surface and preparation method of self-lubricating wear-resistant composite coating

A composite coating, self-lubricating technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of surface hardness and wear resistance of single titanium alloy, unfavorable application of titanium alloy, no friction reduction, etc. Excellent anti-wear effect, cost-effective, reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Correspondingly, the application provides a method for preparing a self-lubricating and wear-resistant composite coating on the surface of a titanium alloy, comprising the following steps:

[0057] The mixed alloy powder and binder are mixed and coated on the surface of the titanium alloy to form a pre-paved coating. The mixed alloy powder includes:

[0058] 59wt% ~ 62wt% nickel;

[0059] 18.5wt% to 21wt% chromium;

[0060] 5wt%-8wt% boron;

[0061] 6.5 wt% to 10 wt% silicon; and

[0062] 3wt%~7wt% hexagonal boron nitride;

[0063] A laser beam is used to irradiate the pre-laid coating to obtain a self-lubricating and wear-resistant composite coating for the surface of the titanium alloy.

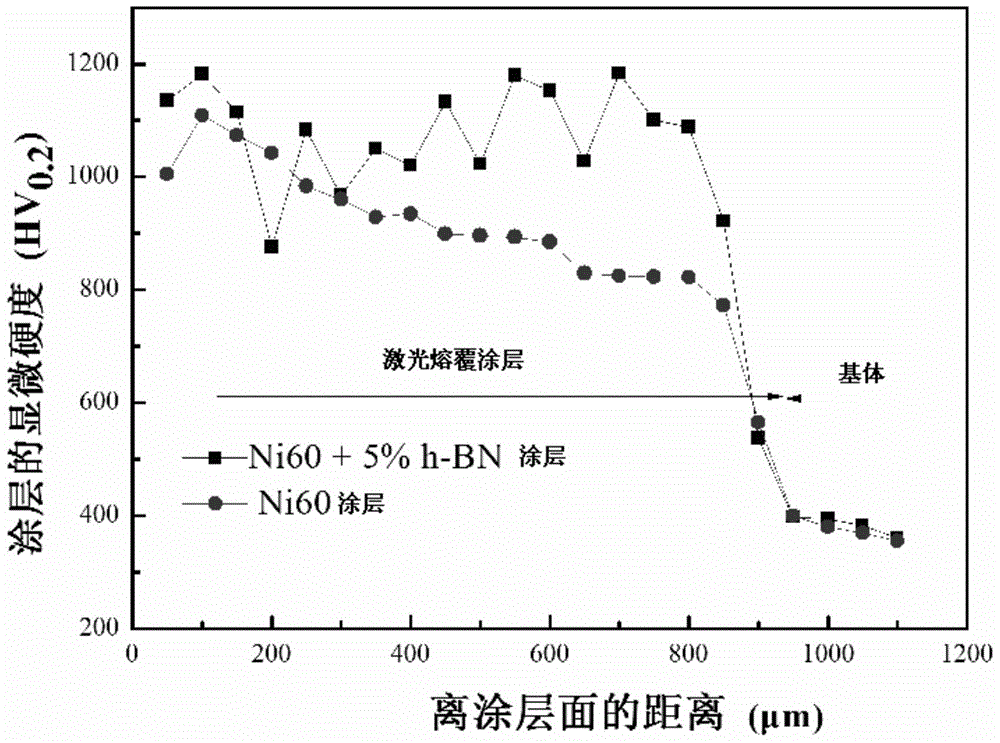

[0064] This application utilizes laser cladding technology and adds hexagonal boron nitride (h-BN) to prepare a self-lubricating and wear-resistant composite coating material with good self-lubricating properties in a wide temperature range from room temperature to 600°C. Applic...

Embodiment 1

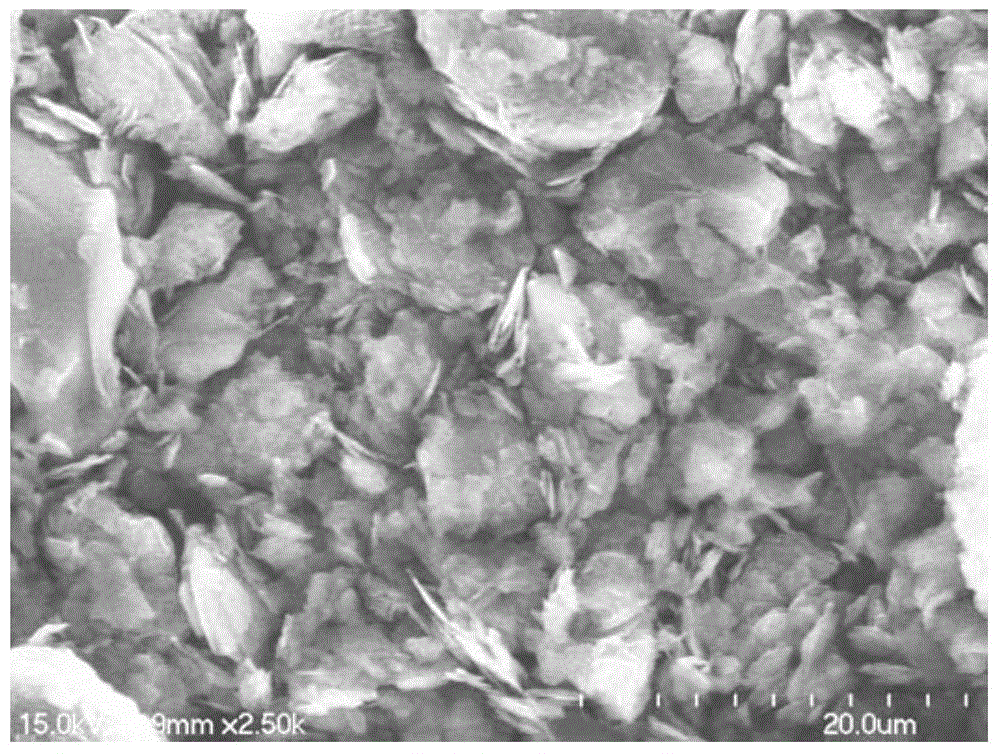

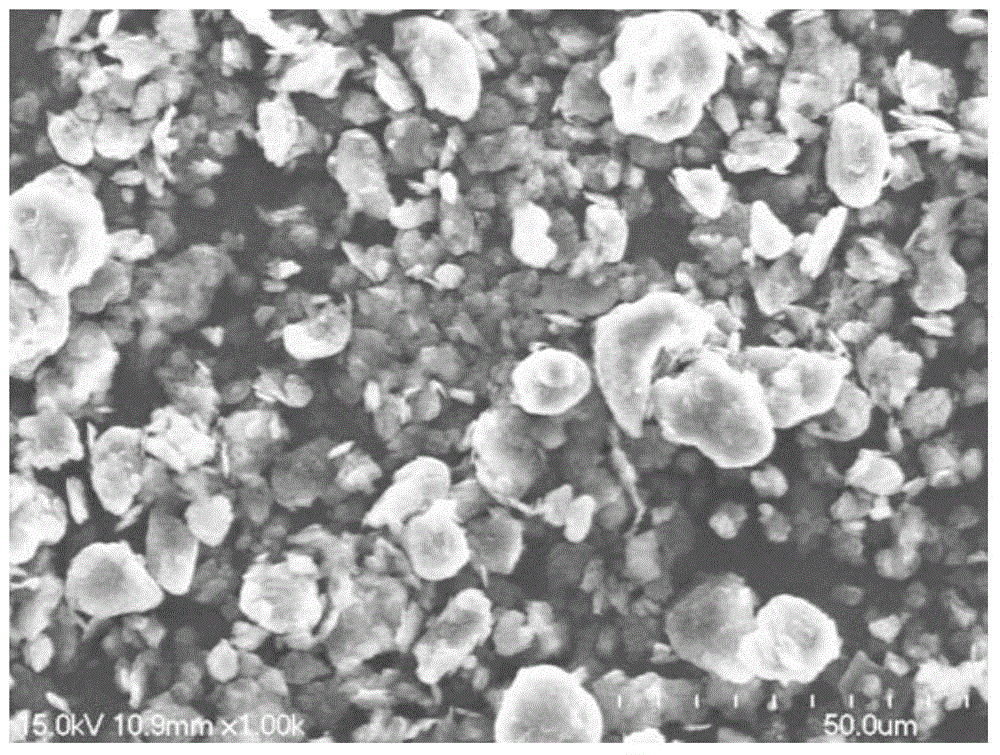

[0083] 60 wt% nickel with a particle size of 15 μm to 45 μm, 20 wt% chromium with a particle size of 15 μm to 45 μm, 6.5 wt% boron with a particle size of 15 μm to 45 μm, 8.5 wt% silicon with a particle size of 15 μm to 45 μm and 5 wt% silicon with a particle size of 0.2 μm ~1.5μm hexagonal boron nitride, mixed and dried by mechanical ball milling method to obtain mixed alloy powder;

[0084] Dissolving methyl cellulose in ether, adding the mixed alloy powder to make a paste, coating the surface of Ti6Al4V titanium alloy, and drying to obtain a pre-coat;

[0085] The laser beam with a power of 1.2kW is used to scan and irradiate the pre-coated coating to obtain a self-lubricating and wear-resistant composite coating for the surface of the titanium alloy; wherein, the size of the laser beam is 4 mm in length and 3 mm in width, and the scanning speed is is 2mm / s.

Embodiment 2

[0087] 60 wt% nickel with a particle size of 15 μm to 45 μm, 20 wt% chromium with a particle size of 15 μm to 45 μm, 6.5 wt% boron with a particle size of 15 μm to 45 μm, 8.5 wt% silicon with a particle size of 15 μm to 45 μm and 5 wt% silicon with a particle size of 0.2 μm ~1.5μm hexagonal boron nitride, mixed and dried by mechanical ball milling method to obtain mixed alloy powder;

[0088] Dissolving methyl cellulose in ether, adding the mixed alloy powder to make a paste, coating the surface of Ti6Al4V titanium alloy, and drying to obtain a pre-coat;

[0089] The laser beam with a power of 1.2kW is used to scan and irradiate the pre-coated coating to obtain a self-lubricating and wear-resistant composite coating for the surface of the titanium alloy; wherein, the size of the laser beam is 4 mm in length and 3 mm in width, and the scanning speed is It is 3mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com