Solid lubricating high-temperature anti-wearing powder composition and preparation method of compound coating of composition

A high-temperature wear-resistant, composite coating technology, applied in the direction of coating, to achieve the effect of improving high-temperature wear-resistant and anti-friction performance, saving costs, and excellent high-temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Tungsten disulfide (WS 2 ) powder surface treatment such as pickling, alkali washing and activation, and then nickel sulfate (Ni 2 SO 4 ·6H 2 O) as the main salt, sodium hypophosphite (NaH 2 PO 2 ·H 2 O) is the reducing agent, including complexing agent, catalyst, buffering agent, etc., and the plating solution is prepared, and tungsten disulfide (WS 2 ) powder in the plating solution, using the electroless plating process, the plating temperature is 88 ℃, the plating time is 3 hours, and the plating solution is fully stirred during plating to ensure that the particles are dispersed, and the surface-coated Ni-P alloy disulfide is obtained. Tungsten, counted as WS 2 (Ni-P).

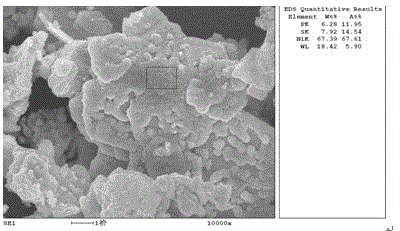

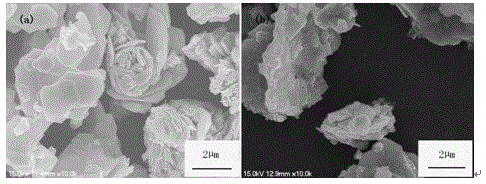

[0021] See attached figure 1 , the tungsten disulfide (WS) coated with Ni-P alloy provided by this embodiment 2 (Ni-P)) powder EDS energy spectrum; carry out energy spectrum analysis on the Ni-P cladding layer of the area taken, and measure the content of each element, by figure 1 It can b...

Embodiment 2

[0024] Adopt the chemical plating method of embodiment one to prepare WS 2 (Ni-P), according to table 1 weight percent proportioning each element, obtains NiCr-Cr with mechanical ball mill mixing method 3 C 2 / WS 2 (Comparative example, WS 2 30wt.%) and NiCr-Cr 3 C 2 / WS 2 (Ni-P) (WS 2 (Ni-P) is 30wt.%) alloy powder mixture, the powder particle size reaches 200-300 mesh.

[0025] Table 1

[0026]

[0027] (3) Use methyl cellulose as a binder, mix it with the above two powder mixtures respectively to form a paste, spread a pre-coated layer on the surface of austenitic stainless steel (0Cr18Ni9), and dry it.

[0028] (4) Irradiate the pre-coated coating with a laser with a power of 1.5 kW, and blow inert gas to the molten pool at the same time to avoid oxidation of the molten pool surface; the laser uses CO 2 Laser, the rectangular spot size is 6 mm × 3 mm, and the laser scanning speed is 4 mm / s.

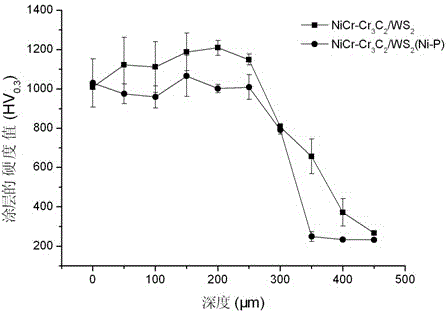

[0029] (5) According to the size of the austenitic stainless steel (...

Embodiment 3

[0044] The alloy powder mixture was obtained by the method in Example 2.

[0045] The 2123 phenolic resin material is dissolved in ethanol as an adhesive, and the 2123 phenolic resin is a solid phenolic resin formed by polycondensation of phenol and formaldehyde under the action of an acidic catalyst. The binder is blended with the powder mixture, pre-coated on the surface of austenitic stainless steel (0Cr18Ni9), and dried.

[0046] The pre-laying coating was irradiated with a laser with a power of 1.5 kW, and an inert gas was blown to the molten pool to avoid oxidation of the surface of the molten pool; the laser used CO 2 Laser, the rectangular spot size is 6 mm × 3 mm, and the laser scanning speed is 4 mm / s.

[0047] According to the size of the austenitic stainless steel (0Cr18Ni9) substrate, a continuous coating can be obtained by single-pass laser scanning or multi-pass laser scanning. The lapping rate of multiple laps is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com