Automatic additive manufacturing method and device for robot plasma arc double-cooled filler rod

A plasma arc and additive manufacturing technology, which is applied in the field of automatic additive manufacturing with ion arc double cold filling and wire feeding, can solve the problems of slow forming speed and low deposition efficiency, and achieves improved deposition speed, low cost and high efficiency, The effect of reducing the dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

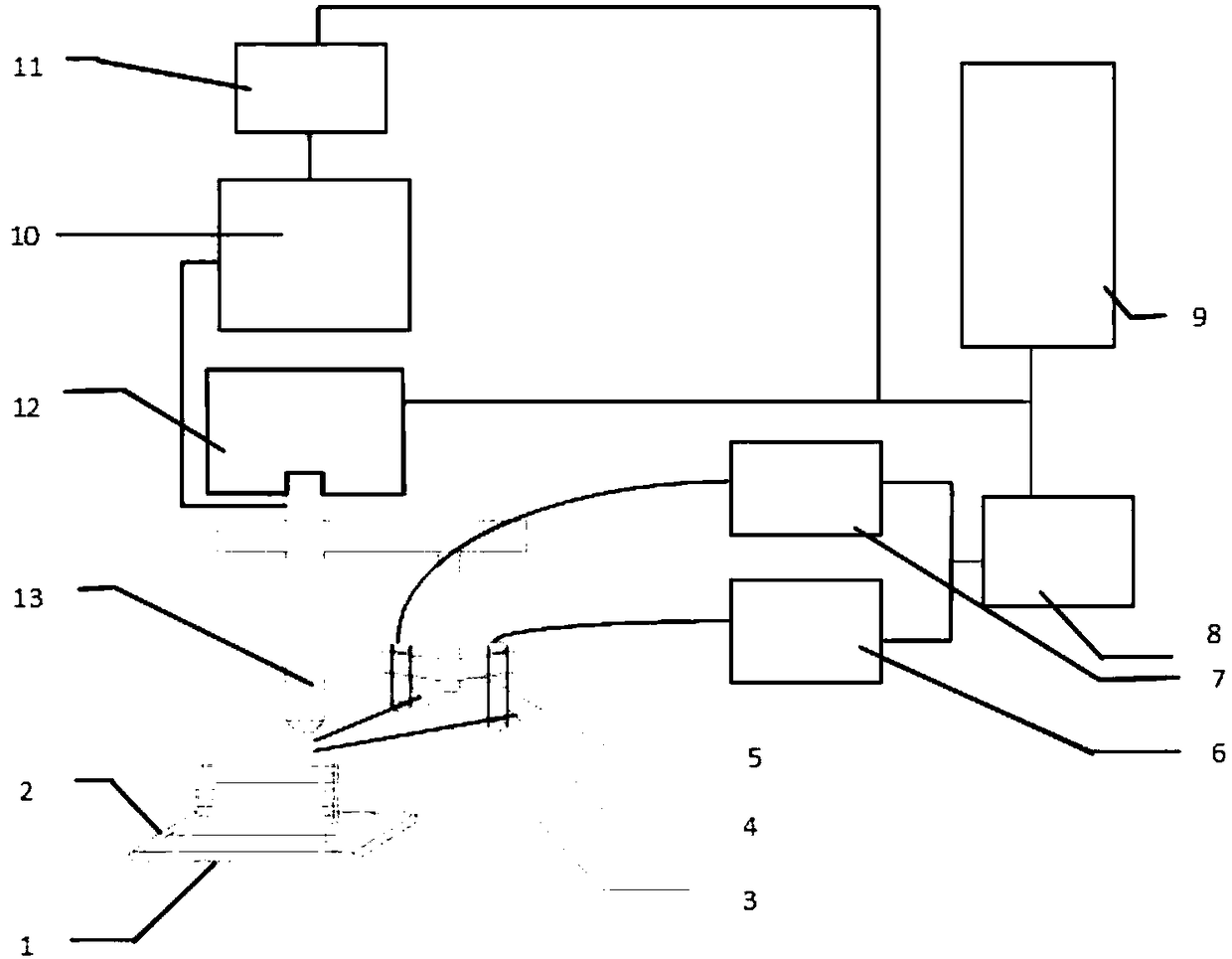

[0039] The invention provides a robotic plasma arc automatic double-feed wire additive manufacturing method, comprising the following steps:

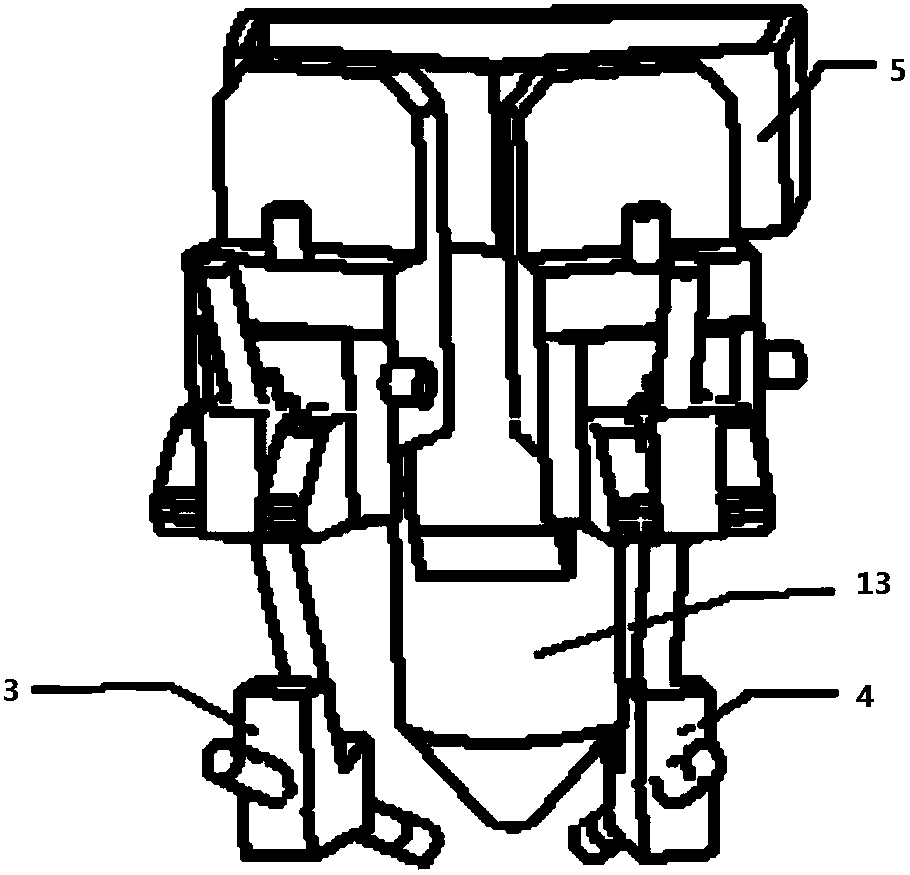

[0040] Step 1, before stacking, adjust the position of wire feed nozzle 3 and wire feed nozzle Ⅱ, so that the end of the wire delivered by the two wire feed nozzles is directly above the substrate on the working platform and 5mm directly below the plasma gun 13 Then fine-tune the knobs on wire feed nozzle 3 and wire feed nozzle Ⅱ, so that the wires sent by the two wire feed nozzles can be melted in the same molten pool;

[0041] Step 2, turn on the power, wait for the communication signal between the robot and the dual-wire coordinator 8 to be ready, and then set the wire feeding speeds of I wire feeder 6 and II wire feeder 7 respectively through the dual-wire coordinator 8, and the I wire feeder The wire feeding speed of 6 and II wire feeder 7 is 1m / min;

[0042]Step 3, the robot 12 carries the plasma torch 13 to the welding starting ...

Embodiment 2

[0049] The invention provides a robotic plasma arc automatic double cold-fill wire additive manufacturing method, comprising the following steps:

[0050] Step 1, before stacking, adjust the position of wire feed nozzle 3 and wire feed nozzle Ⅱ, so that the end of the wire delivered by the two wire feed nozzles is directly above the substrate on the working platform and 4mm directly below the plasma gun 13 Then fine-tune the knobs on wire feed nozzle 3 and wire feed nozzle Ⅱ, so that the wires sent by the two wire feed nozzles can be melted in the same molten pool;

[0051] Step 2, turn on the power, wait for the communication signal between the robot and the dual-wire coordinator 8 to be ready, and then set the wire feeding speeds of I wire feeder 6 and II wire feeder 7 respectively through the dual-wire coordinator 8, and the I wire feeder The wire feeding speed of 6 is 0.8m / min, and the wire feeding speed of II wire feeder 7 is 1.2m / min;

[0052] Step 3, the robot 12 carri...

Embodiment 3

[0059] The invention provides a robotic plasma arc automatic double cold-fill wire additive manufacturing method, comprising the following steps:

[0060] Step 1, before stacking, adjust the position of wire feed nozzle 3 and wire feed nozzle Ⅱ, so that the end of the wire delivered by the two wire feed nozzles is directly above the substrate on the working platform and 6mm directly below the plasma gun 13 Then fine-tune the knobs on wire feed nozzle 3 and wire feed nozzle Ⅱ, so that the wires sent by the two wire feed nozzles can be melted in the center of the molten pool;

[0061] Step 2, turn on the power, wait for the communication signal between the robot and the dual-wire coordinator 8 to be ready, and then set the wire feeding speeds of I wire feeder 6 and II wire feeder 7 respectively through the dual-wire coordinator 8, the preset The wire feeding speed is 0.8m / min;

[0062] Step 3, the robot 12 carries the plasma torch 13 to the starting welding position, the robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com