Method for performing laser cladding by using multiple lasers

A laser cladding and multi-laser technology, which is applied in the field of laser processing, can solve the problems of cracks and pores in the cladding layer, low laser cladding efficiency, and high processing costs, and achieve no cracks and pores, reduce processing costs, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

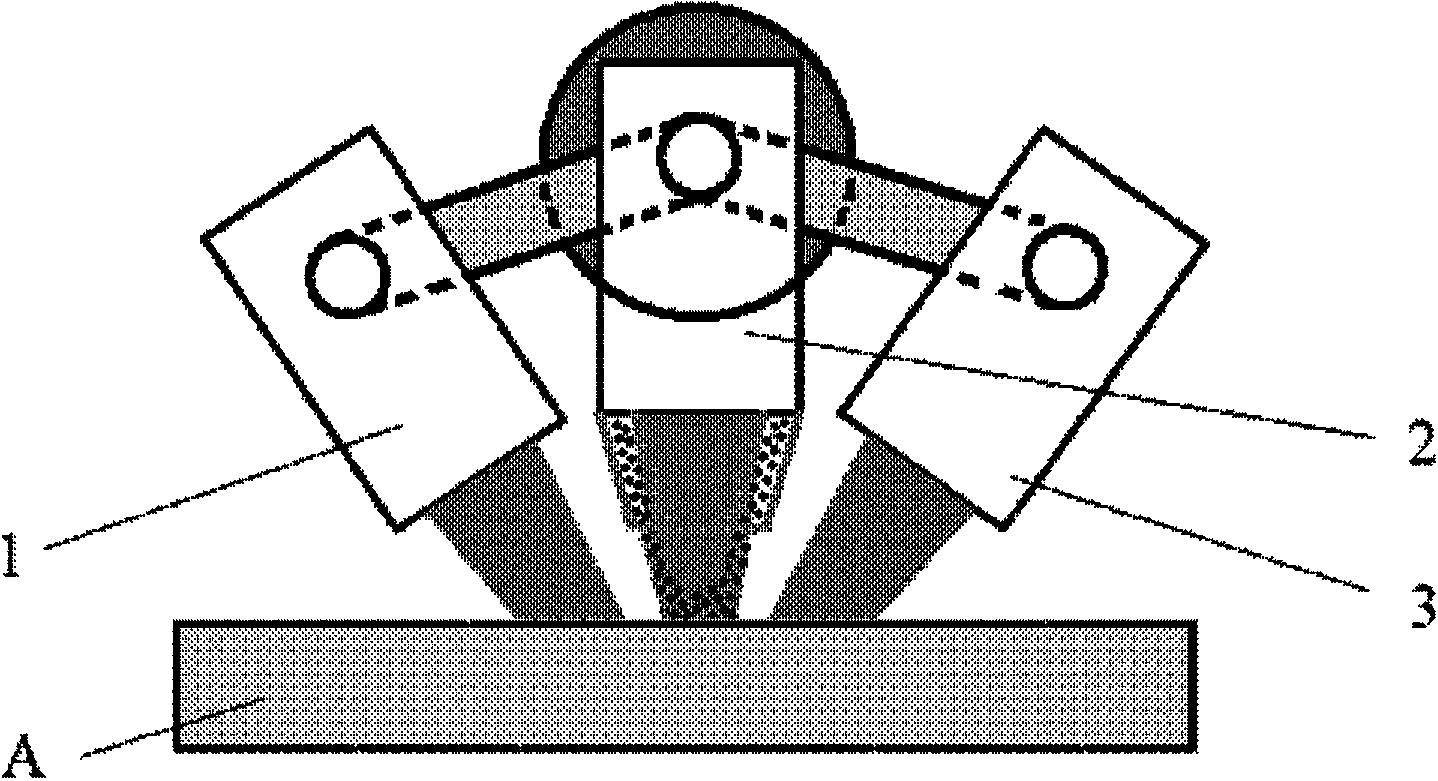

[0039] The implementation process of this embodiment is as follows figure 2 shown.

[0040] (1) Wipe off the oil stains on the surface of Q235 substrate A with acetone;

[0041] (2) The laser beam output by the first laser is focused on the surface of the Q235 substrate A through the laser head 1, and preheated to increase the absorption rate of the Q235 substrate A to the laser beam of the second laser, and reduce the laser cladding process. Thermal stress, the laser power of the first laser is 600W, so that the preheating temperature of the substrate is 400-500°C;

[0042] (3) The laser beam output by the second laser irradiates the surface of the Q235 substrate A through the laser head 2 to melt the surface of the Q235 substrate (A) to form a molten pool; the laser power of the second laser is 1.2kW;

[0043](4) The laser head 2 of the second laser is equipped with a synchronous powder feeding nozzle, and the powder feeder and the synchronous powder feeding nozzle are us...

Embodiment 2

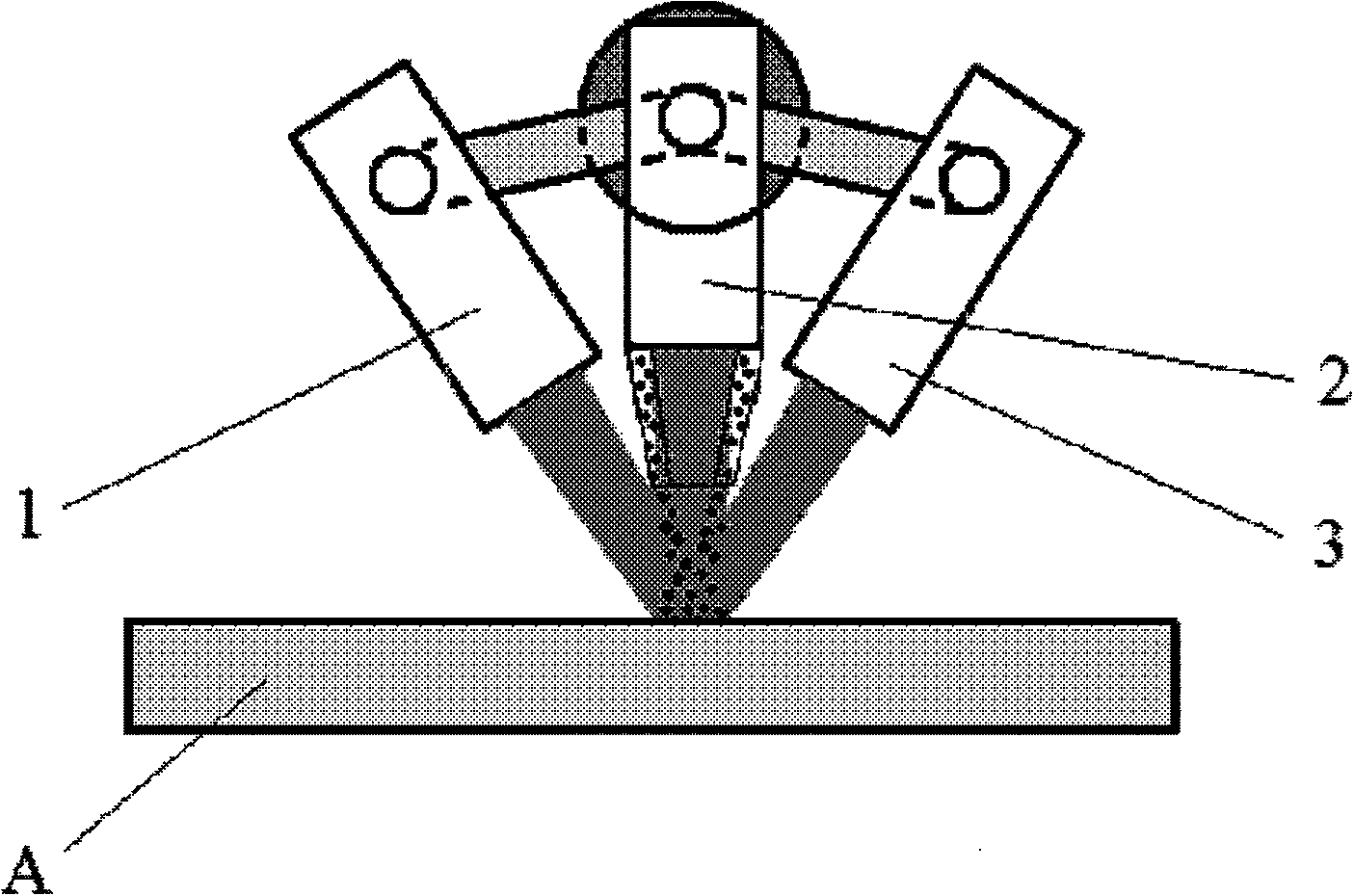

[0047] The implementation process of this embodiment is as follows image 3 shown.

[0048] (1) Wipe off the oil stains on the surface of 27SiMn hydraulic prop A with acetone;

[0049] (2) There is no preheating in the laser cladding process, and three 1KW fiber lasers are used for laser cladding directly;

[0050] (3) The laser beams generated by the three lasers are focused on the same position on the surface of the 27SiMn hydraulic prop A through the processing heads 1, 2, and 3, so that the surface of the 27SiMn hydraulic prop A is melted to form a molten pool. The spot diameters of the three laser beams of the three lasers Both are 3mm, and the center of the light spot on the surface of the substrate completely overlaps. The power of each laser is 800W, which is equivalent to a 2400W laser for laser cladding processing:

[0051] (4) The laser head 2 of the second laser is equipped with a synchronous powder feeding nozzle. Fe-based alloy powder is fed into the molten po...

Embodiment 3

[0055] The implementation process of this embodiment is as follows Figure 4 shown.

[0056] (1) Wipe off the oil stains on the surface of 304 stainless steel A with acetone;

[0057] (2) There is no preheating in the laser cladding process, and three 2KW solid-state lasers are used for laser cladding directly;

[0058] (3) The laser beams generated by the three lasers are focused on the surface of 304 stainless steel A through processing heads 1, 2, and 3. The spot diameter of the three laser beams on the surface of 304 stainless steel A is 4mm, and the three spots overlap. The second laser The laser power output by the laser head 2 of the first laser is 1200W, and the laser power output by the laser head 1 of the first laser and the laser head 3 of the third laser are both 1600W.

[0059] (4) using a powder feeder and a separately configured lateral powder feeding nozzle 4 to feed the Ni-based alloy powder into the molten pool of the base material;

[0060] (5) Natural co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com