Laser-induction compounded cladding method for repairing continuous casting crystallizer

A continuous casting crystallizer and laser technology, applied in metal material coating process, coating, etc., to achieve the effects of increased service life, controllable thickness, and low dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

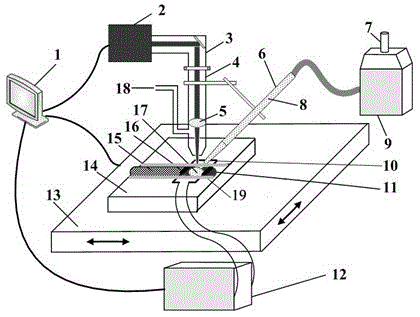

[0023] The chemical composition of the continuous casting mold is: Cr 0.5~1.5 wt.%, Zr 0.08~0.3 wt.%, and the balance is Cu. The size of the damaged part of the continuous casting mold is: 100mm×50mm×30 mm (length×width × high), the specific implementation process of laser-induction composite cladding repair is as follows: figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0024] (1) Use special copper-based alloy powder 8 for laser induction composite cladding repair treatment, its chemical composition is: Ni 8 wt.%, Sn 8.5 wt.%, Al 7 wt.%, Si 0.8 wt.%, balance Be Cu, its average particle diameter is 65 μ m, then packs in the loading hopper 7 of automatic powder feeder 9;

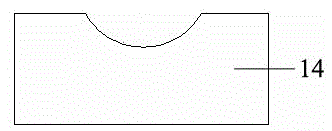

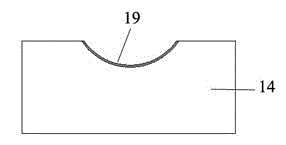

[0025] (2) The surface of the damaged part of the continuous casting crystallizer 14 is derusted, degreased and surface activated, and a layer of nickel alloy 19 with a thickness of 8 μm is electroplated on the surface by electroplating. Among them, the electroplating nickel formula i...

Embodiment 2

[0032] The chemical composition of the continuous casting mold is: Co 2.0~3.0 wt.%, Be 0.2~0.8 wt.%, Ni 0.1~0.4 wt.%, Fe 0.2~0.5 and the balance is Cu. The size of the damaged part of the continuous casting mold It is: 90mm×60mm×25 mm (length×width×height), the specific implementation process of laser-induction composite cladding repair is as follows figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0033] (1) Use special copper-based alloy powder 8 for laser induction composite cladding repair treatment, its chemical composition is: Ni 9 wt.%, Sn 8 wt.%, Al 12 wt.%, Si 1.2 wt.%, balance Be Cu, its average particle diameter is 40 μ m, then packs in the loading hopper 7 of automatic powder feeder 9;

[0034] (2) The surface of the damaged part of the continuous casting crystallizer 14 is derusted, degreased and surface activated, and a layer of nickel alloy 19 with a thickness of 12 μm is electroplated on the surface by electroplating. Among them, the ele...

Embodiment 3

[0041] The chemical composition of the continuous casting mold is: Cr 0.3~1.0 wt.%, Zr 0.1~0.5 wt.%, Fe 0.2~0.6 wt.%, Ti 0.1~0.3 wt.%, the balance is Cu, the continuous casting mold The size of the damaged part is: 100 mm × 50 mm × 30 mm (length × width × height). The specific implementation process of laser-induction composite cladding repair is as follows: figure 1 , figure 2 , image 3 and Figure 4 Shown:

[0042] (1) Use special copper-based alloy powder 8 for laser induction composite cladding repair treatment, its chemical composition is: Ni 8.7 wt.%, Sn 8 wt.%, Al 14.6 wt.%, Si 1.8 wt.%, balance Be Cu, its average particle diameter is 60 μ m, then packs in the loading hopper 7 of automatic powder feeder 9;

[0043] (2) The surface of the damaged part of the continuous casting crystallizer 14 is derusted, degreased and surface activated, and a layer of nickel alloy 19 with a thickness of 15 μm is electroplated on the surface by electroplating. Among them, the elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com