Automatic coating device and coating method of surface coatings of medical catheter

A surface coating and coating device technology, which is applied in the direction of surface coating liquid devices, conduits, coatings, etc., can solve the problem of coating thickness distribution, etc., to increase production, increase production efficiency, and improve coating quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose of the present invention and the advantages of the technical solutions more clearly understood, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

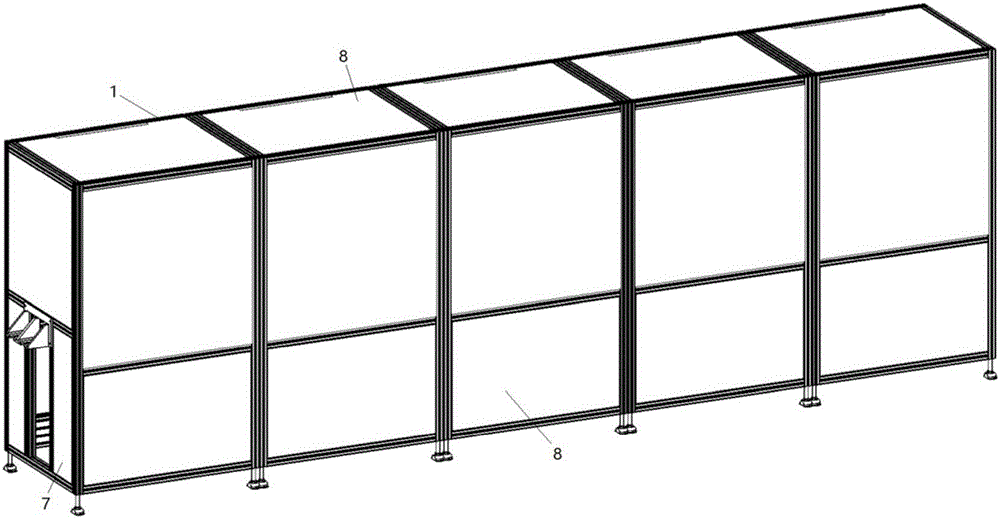

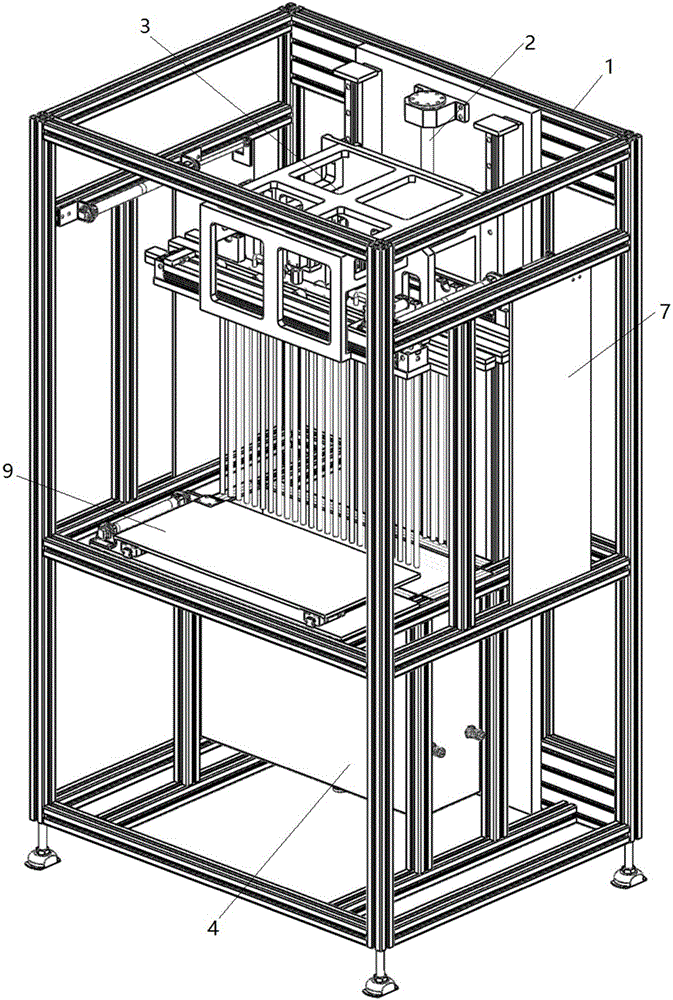

[0045] as attached Figure 1-7 The automatic coating device for the surface coating of the medical catheter shown is composed of five assemblies connected in series in sequence, and the assembly includes a frame 1 and a servo mechanism 2 and a moving platform 3 are installed inside the frame 1;

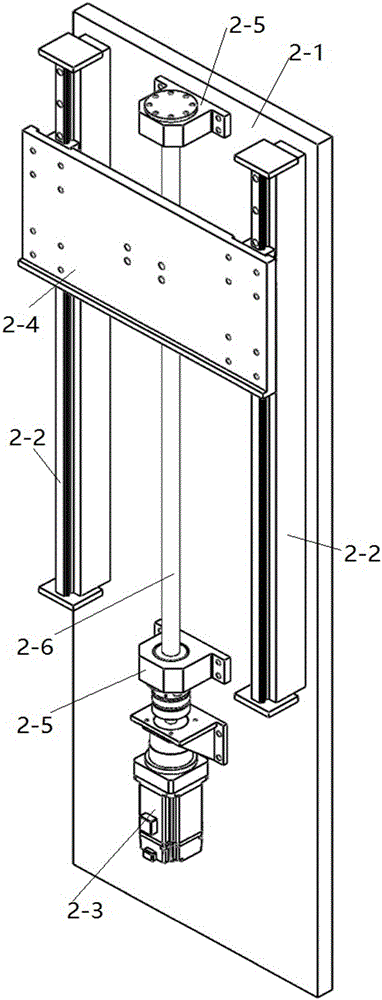

[0046] The servo structure 2 includes a base plate 2-1 vertically installed in the frame 1, a guide rail 2-2 and a motor 2-3 vertically installed on the base plate 2-1, and a sliding base plate is provided on the guide rail 2-2. 2-4. Both ends of the vertically arranged screw rod 2-6 are fixedly connected to the bottom plate 2-1 through the bearing seat 2-5. The screw rod 2-6 passes through the movable block behind the sliding bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com