Automatic cleaning system of conical spiral mixer and cleaning technology for conical spiral mixer

A spiral mixing and automatic cleaning technology, which is applied to mixers with rotating stirring devices, mixers, cleaning methods and utensils, etc., can solve the problems of easy breeding of bacteria, unsatisfactory mixing effect, time-consuming and labor-intensive manual cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

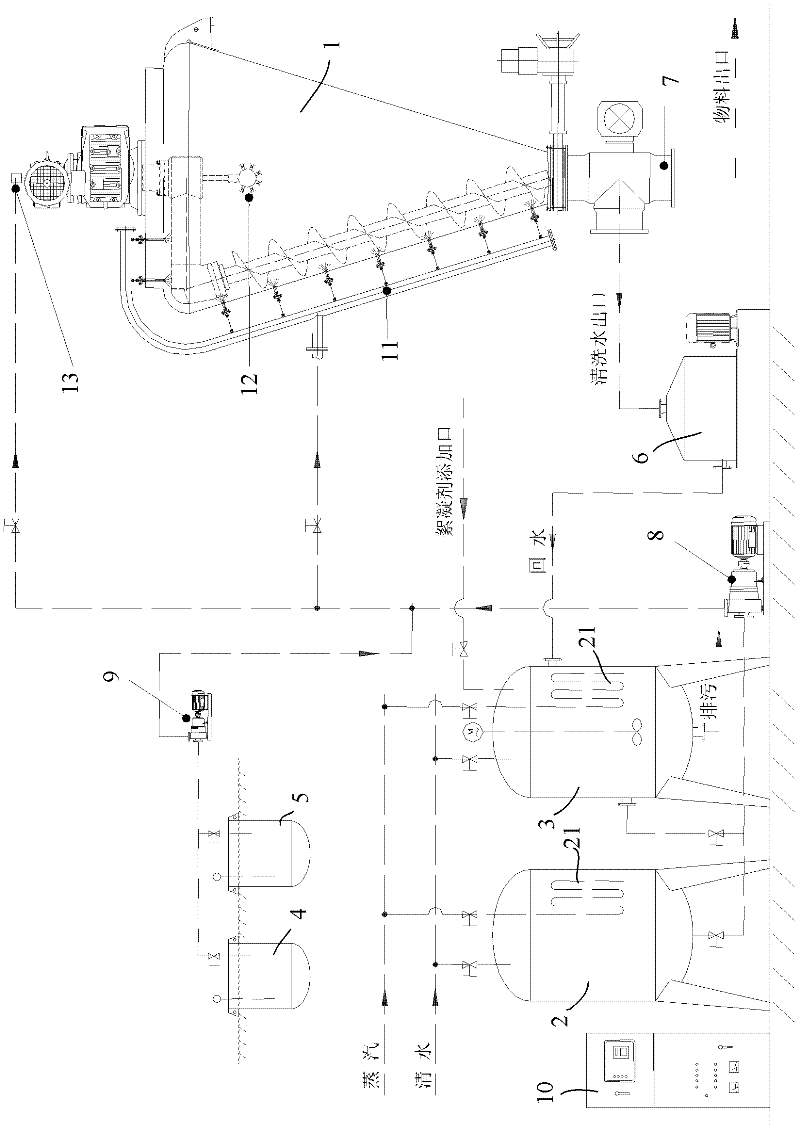

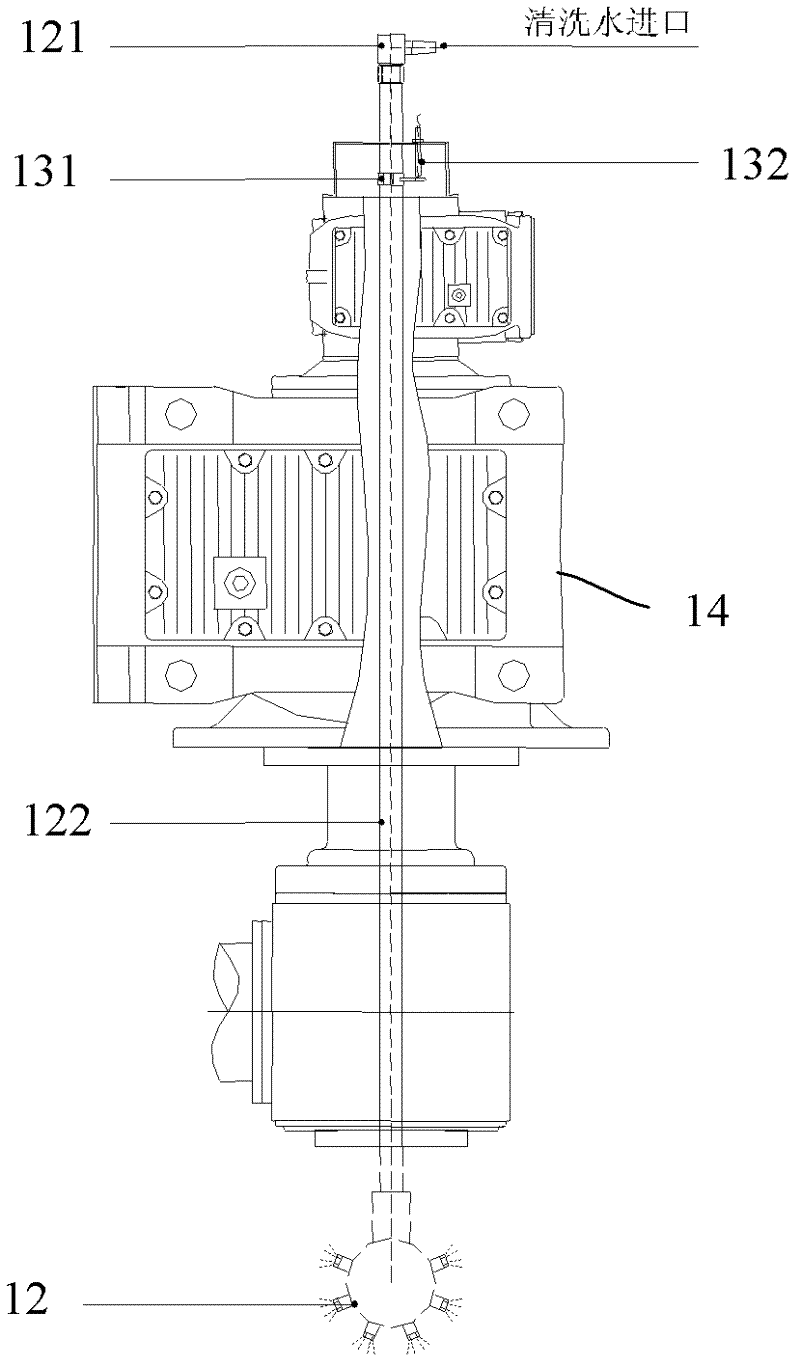

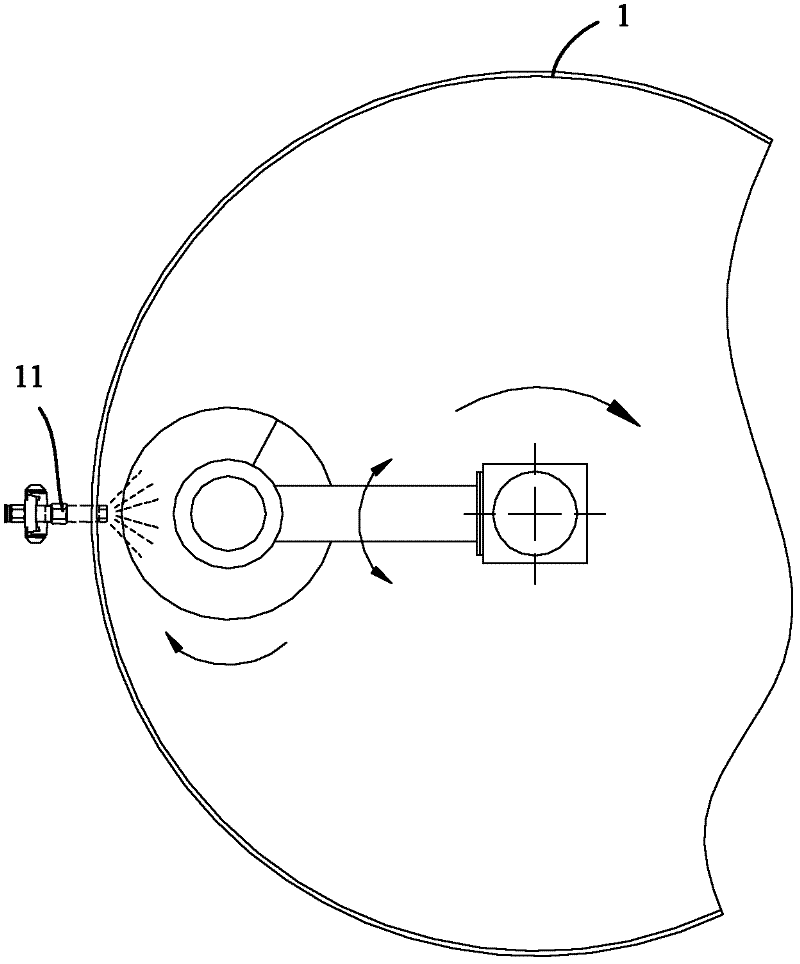

[0016] like figure 1 As shown, the automatic cleaning system of the conical screw mixer includes fixed nozzles 11 installed in groups on the inner wall of the mixer cylinder 1, and rotating cleaning nozzles 12 installed downward at the center of the mixer cylinder 1 and at the top of the driving device 14 , a sensor positioning device 13, a water treatment circulation system and a control system are installed on the top of the mixer driving device 14.

[0017] The fixed nozzle 11 is an integrated ultra-thin cleaning nozzle in a preferred embodiment of the present invention. The meaning of "ultra-thin" is based on the fact that it does not affect the stirring of materials in the mixer. It is usually a cleaning nozzle with a small and exquisite shape. Strong force, the water column is distributed in a fan shape, and is used for positioning and cleaning the stirring propeller in the cylinder body 1. In one embodiment, the nozzle 11 can be self-cleaned by adjusting the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com