Blind hole internal thread chipless cleaning technology and device thereof

A cleaning device and internal thread technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as unguaranteed thread accuracy, blocked threads, and inability to use, etc., to achieve a good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

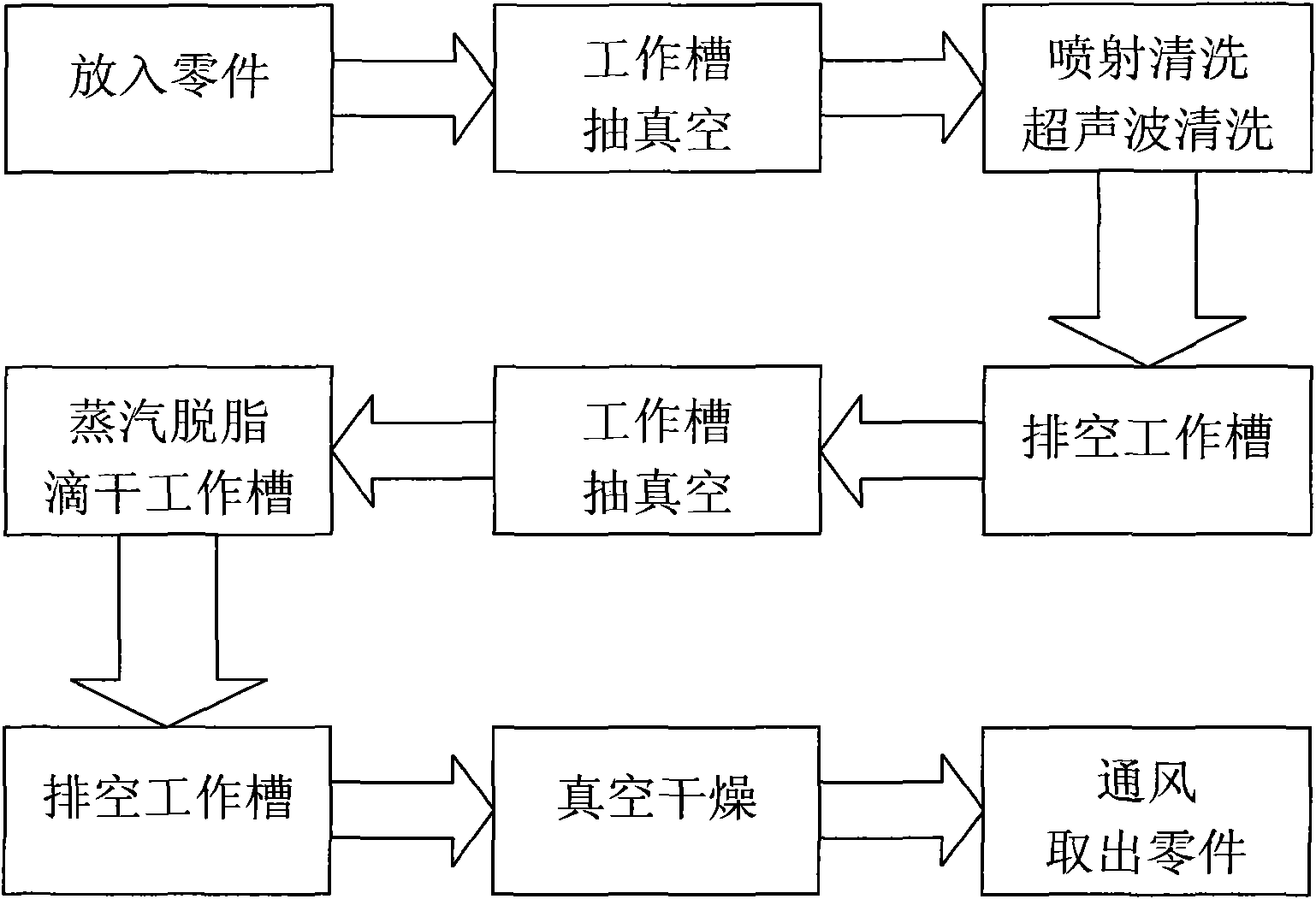

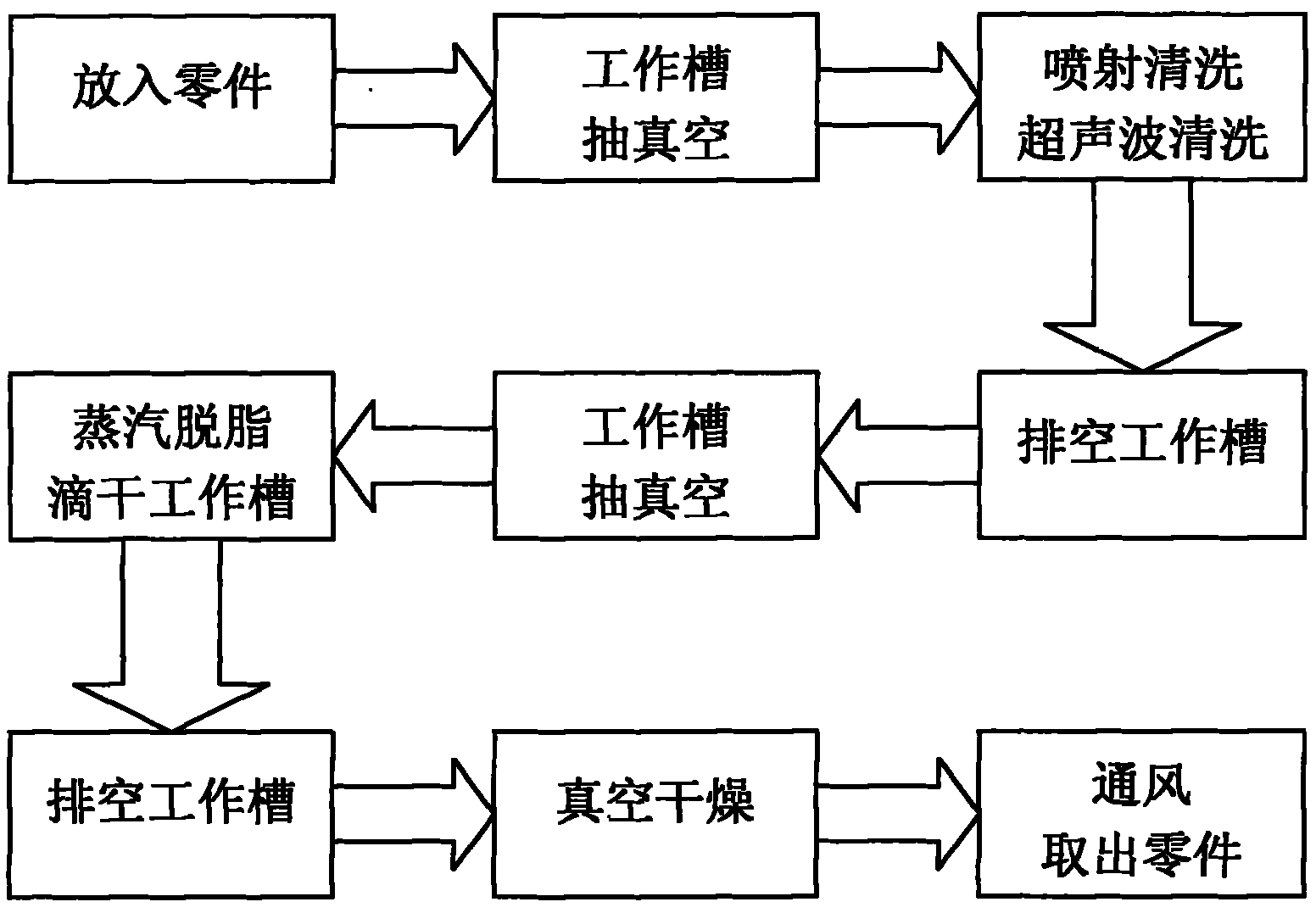

[0030] Such as figure 1 Shown is a blind hole internal thread chipless cleaning technology, the steps of the cleaning technology are:

[0031] ①Put the work basket 2 with parts into the work slot 7;

[0032] ② Vacuumize the working tank 7;

[0033] ③ Pump the liquid in the dipping tank I3 or dipping tank II14 into the working tank 7 for spray cleaning and ultrasonic cleaning at the same time;

[0034] ④ Empty the residue in the working tank 7;

[0035] ⑤ Vacuumize the working tank 7;

[0036] ⑥Steam degreasing, while dripping dry working tank 7;

[0037] ⑦Empty the residue in the working tank 7;

[0038] ⑧ Vacuum drying of parts;

[0039] ⑨ Ventilate and take out the parts.

[0040] In order to achieve green recycling and reuse, before emptying the residue in the working tank 7, the liquid in the working tank 7 should be filtered and recycled to the immersion tank I3 or the immersion tank II14. In order to be able to clean, the step (3) can be cleaned for a long time o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com