Silicon wafer cleaning method for preparing high-efficiency solar cell and cleaning equipment

A technology for cleaning solar cells and silicon wafers, which is applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effect of improving surface hydrophobicity and improving hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

[0024] The purpose and effects of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

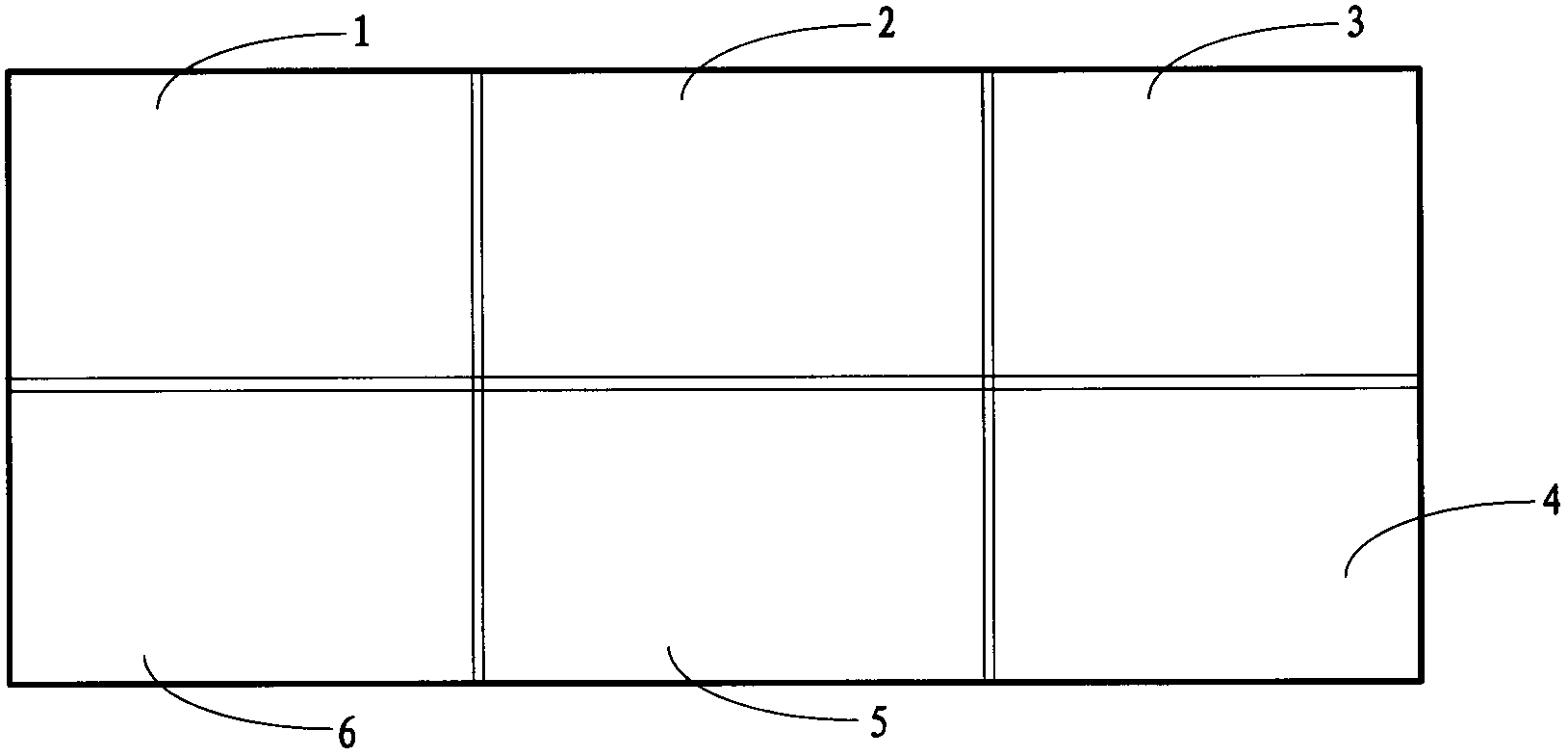

[0025] see figure 1 , the silicon wafer cleaning equipment for preparing high-efficiency solar cells of the present invention comprises a first cleaning tank 1, a first washing tank 2, a second washing tank 3, a second washing tank 4, a third washing tank 5 and a third washing tank 6. The corresponding cleaning solution is set in the corresponding cleaning tank, and the deionized water is set in the corresponding washing tank, and the silicon wafer is cleaned in the corresponding cleaning tank and water washing tank by soaking or spraying. The cleaning device can also be provided with a mechanical device that automatically transfers the silicon wafers between the slots, which is a known technology in the industry and will not be repeated here.

[0026] The cleaning solution in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com