Patents

Literature

38results about How to "Avoid readsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for ultrasonic cleaning of polished sapphire substrate wafer

ActiveCN103537453AImprove oxidation capacityAvoid readsorptionCleaning using liquidsElectrolysisMetal impurities

The invention relates to a method for ultrasonic cleaning of a polished sapphire substrate wafer and provides a method for conducting cleaning through ultrasound and a solution to remove particles and metal ions and then conducting cleaning through ultrasound and oxidation liquid to remove organic matters. According to removal of the particles and the metal ions, an FA / O type chelating agent and two kinds of non-ionic surface active agents including JFC and AEO are selected and prepared to mixed liquid in proportion and the ultrasonic action is added so that cleaning can be conducted; anodic oxidation liquid obtained through electrolysis of a diamond film (BDD) is selected to remove organic pollution, the oxidation liquid is high in oxidation function, and therefore most organic matters are resolved. According to the method, comprehensive cleaning of the particles, the organic matters and metal impurities is conducted, the number of steps is small, operation is simple, and the method can satisfy the requirement of the new-period micro-electronic cleaning technology.

Owner:江西伟嘉创展企业管理有限公司

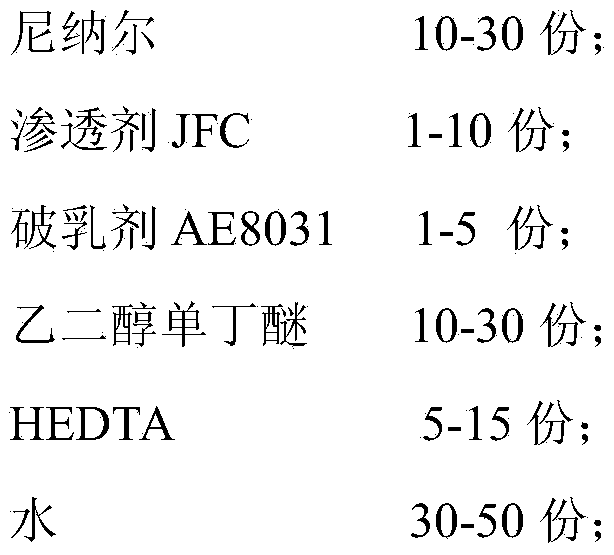

Cleaning agent for heat cleaning of wellhole and preparation method thereof

The invention relates to a cleaning agent for heat cleaning of wellhole. The cleaning agent comprises the following components, by weight: 10-30 parts of Ninol, 1-10 parts of a penetrating agent JFC, 1-5 parts of a demulsifier AE8031, 10-30 parts of ethylene glycol monobutyl ether; 5-15 parts of HEDTA and 30-50 parts of water. The preparation method comprises the steps of: (1) dissolving HEDTA in water, and stirring until complete dissolving; and (2) adding ethylene glycol monobutyl ether into the solution from the step (1), stirring evenly, successively adding Ninol, penetrating agent JFC and demulsifier AE8031, and stirring evenly to obtain a finished product. The components of Ninol, penetrating agent JFC, demulsifier AE8031 and ethylene glycol monobutyl ether in the cleaning agent are all surfactants; HEDTA has descaling and scale inhibition function, so that the cleaning agent provided by the invention has the functions of surface activity, descaling and scale inhibition, and is suitable for cleaning of oil tubes in heavy oil heavy oil fields, and also has the function of environmental protection.

Owner:CNOOC ENERGY TECH & SERVICES +1

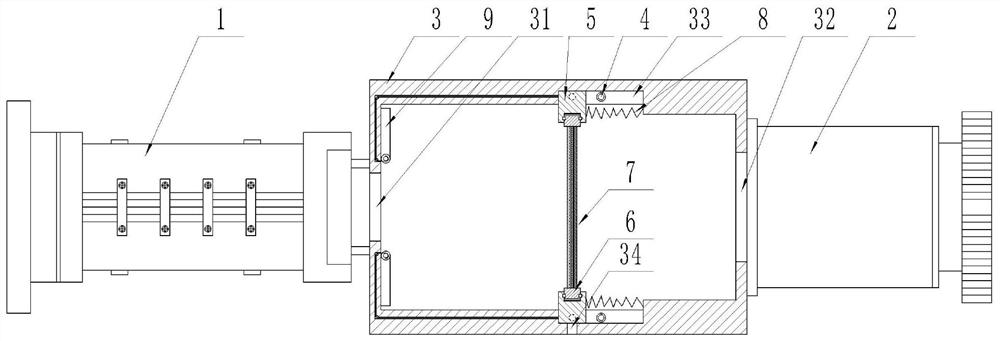

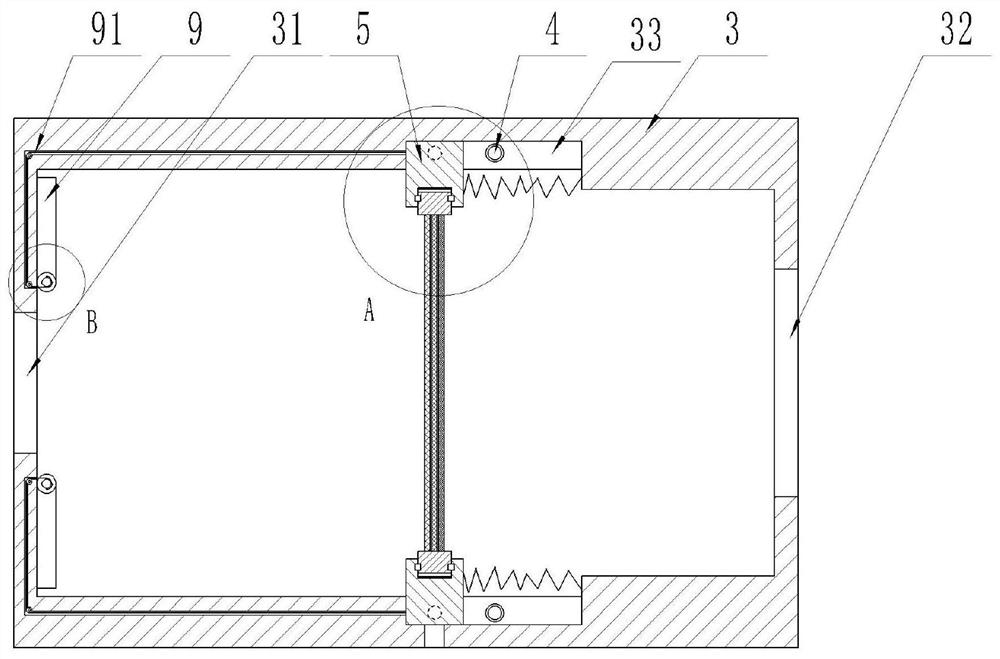

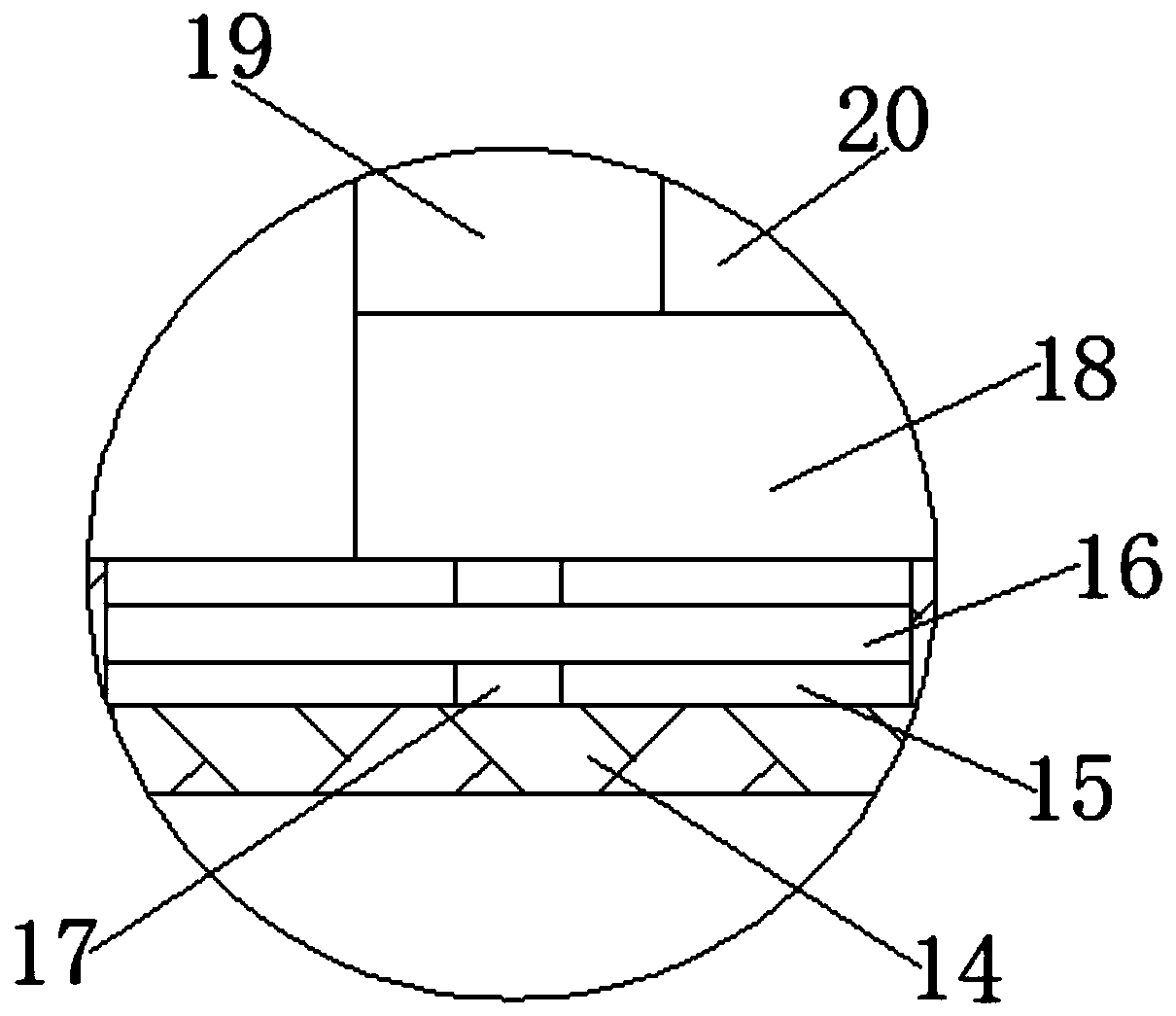

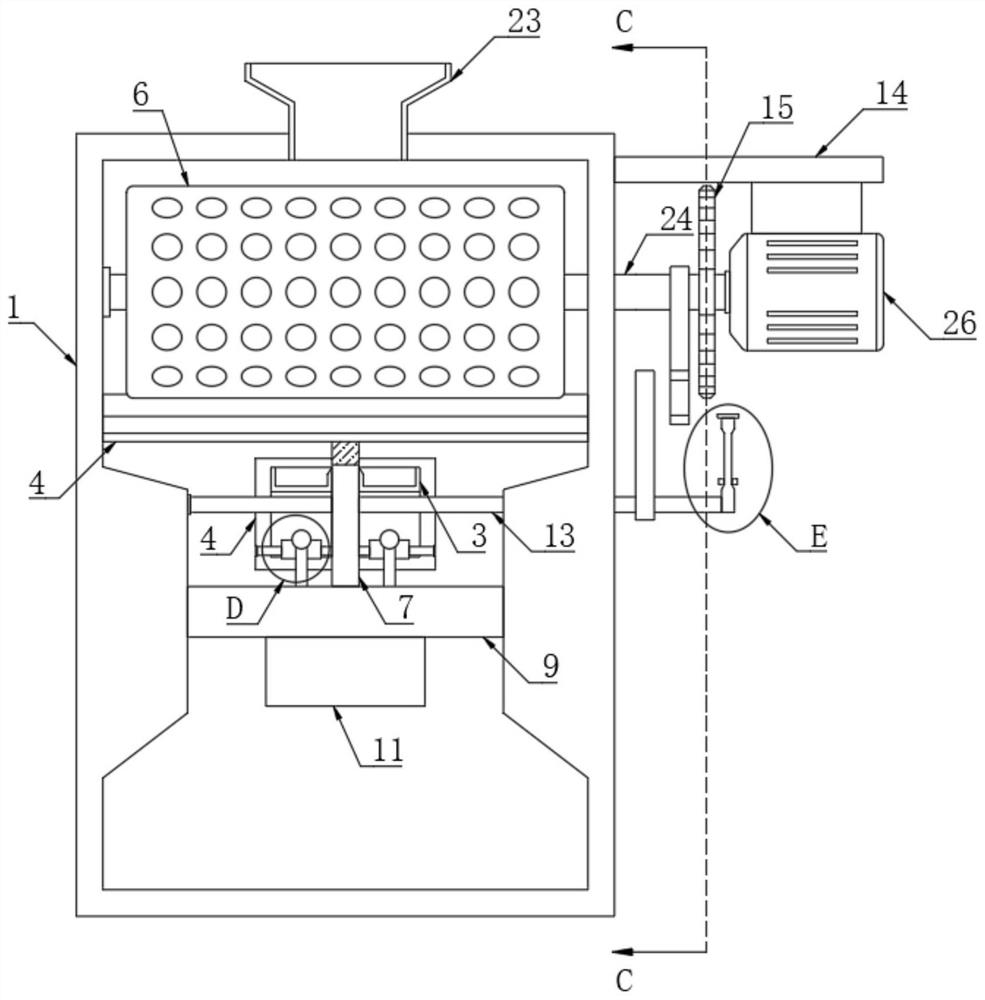

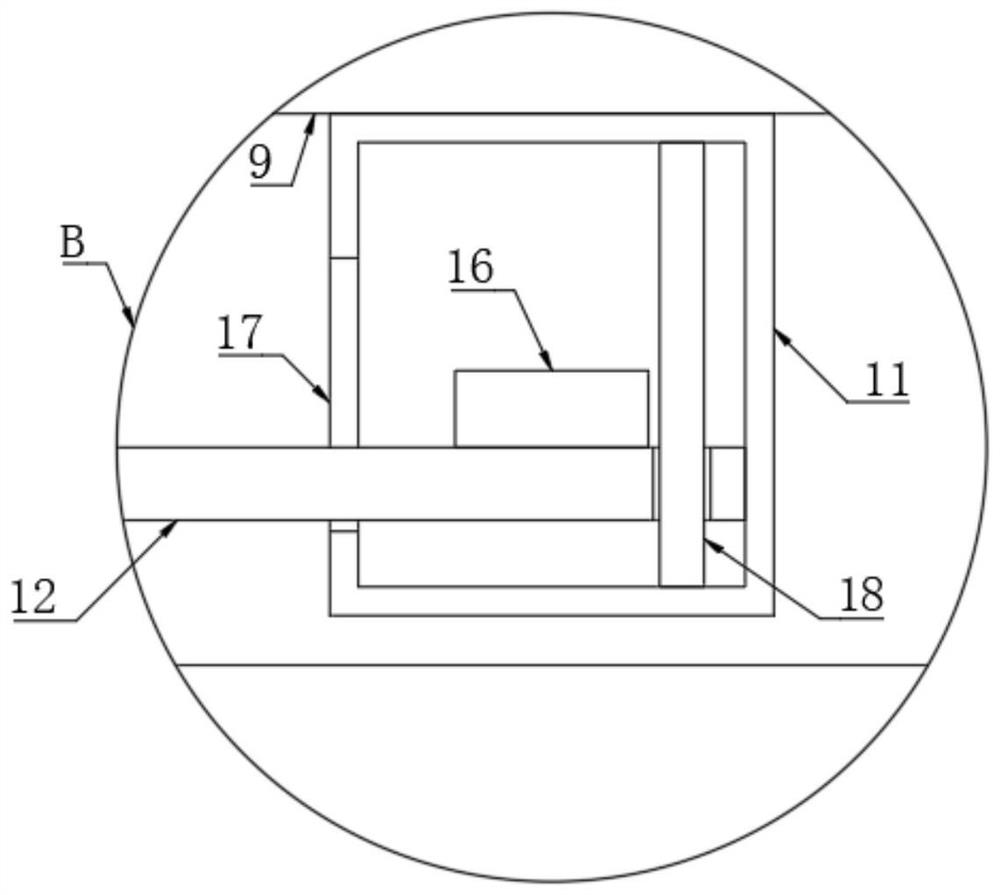

Automatic blockage-clearing waste gas filtering device and method

PendingCN112337217AAvoid emission non-complianceImprove filtration efficiencyDispersed particle filtrationTransportation and packagingProcess engineeringHigh frequency vibration

The invention discloses an automatic blockage-clearing waste gas filtering device and relates to the technical field of waste gas clearing equipment. The device comprises a cleaning and filtering mechanism; the cleaning and filtering mechanism comprises a sliding chute, a vibration head, a sliding block, a negative pressure port, a connecting ring, a filtering unit and a sealing plate; the filtering unit accumulating a large number of particles slides rightwards after bearing enough waste gas pressure; firstly, a sliding block on the side of the filtering unit is in butt joint with a vibrationblock, so that the filtering unit is affected by high-frequency vibration, and the particles on the filtering unit are rapidly shaken off; and secondly, after the sliding block moves, the negative pressure port is opened to suck and clean the shaken-off particles, so that secondary adsorption is avoided; and thirdly, after the sliding block moves, the sealing plate can be pulled to seal an air inlet, so that waste gas accumulates pressure in the air inlet, and when the pressure is enough, the sealing plate is pushed away, the sliding block is reset, and waste gas continues to be filtered. Automatic cleaning of the filtering unit after the filtering unit accumulates the particles is facilitated, manual intervention is not needed, and the waste gas filtering efficiency is greatly improved.

Owner:江苏旭龙环境科技有限公司

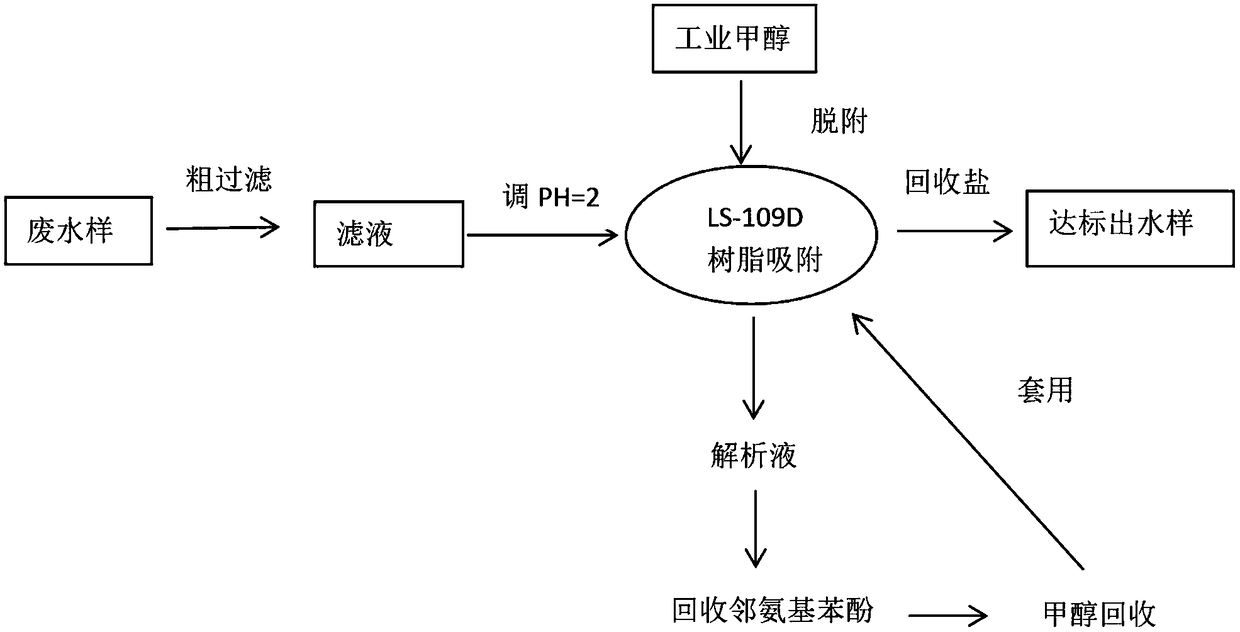

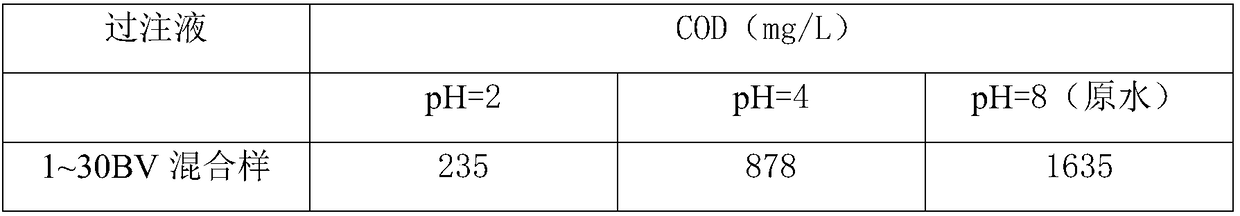

Method for recovering ortho-aminophenol in concentrated brine

InactiveCN108793493AAvoid pollutionHigh recycling efficiencyOrganic compound preparationWater contaminantsHigh concentrationOrganic solvent

The invention discloses a method for recovering ortho-aminophenol in concentrated brine. The method includes adjusting the pH value of high-concentration ortho-aminophenol production wastewater in theconcentrated brine, then introducing into a macroporous styrene series adsorption resin to adsorb the ortho-aminophenol to the macroporous styrene series adsorption resin, utilizing an organic solvent to conduct elution on the saturated macroporous styrene series adsorption resin, and finally recovering the ortho-aminophenol from a solvent desorption solution. According to the method, the problemthat the enterprise water treatment is not up to standard is effectively solved, the economic benefit is improved to the greatest extent, and unification of wastewater treatment and resource recycling is achieved.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD

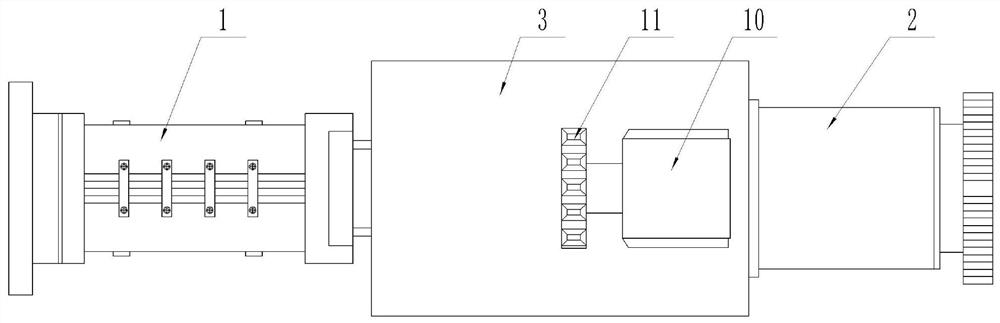

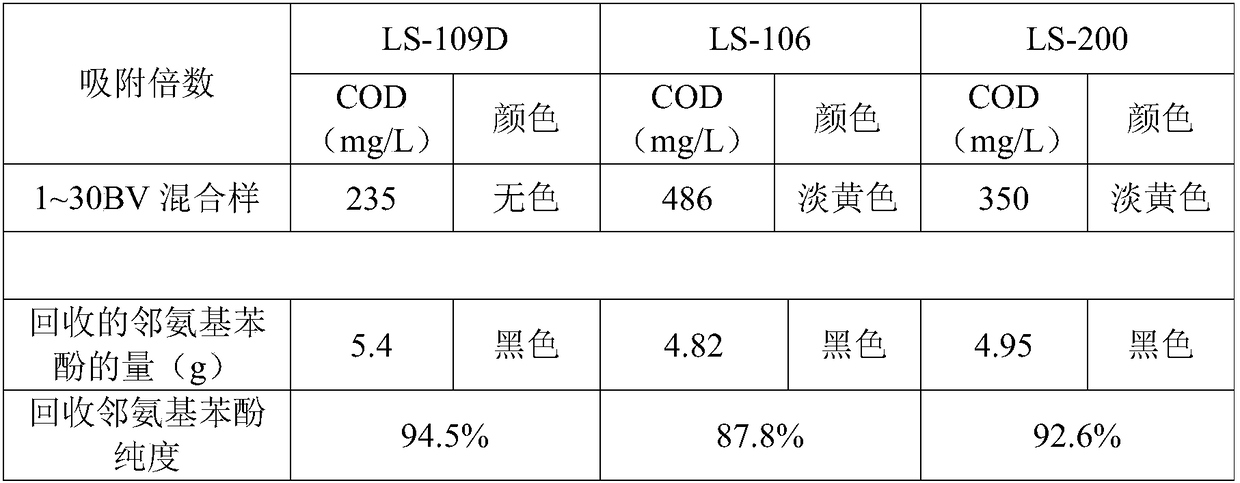

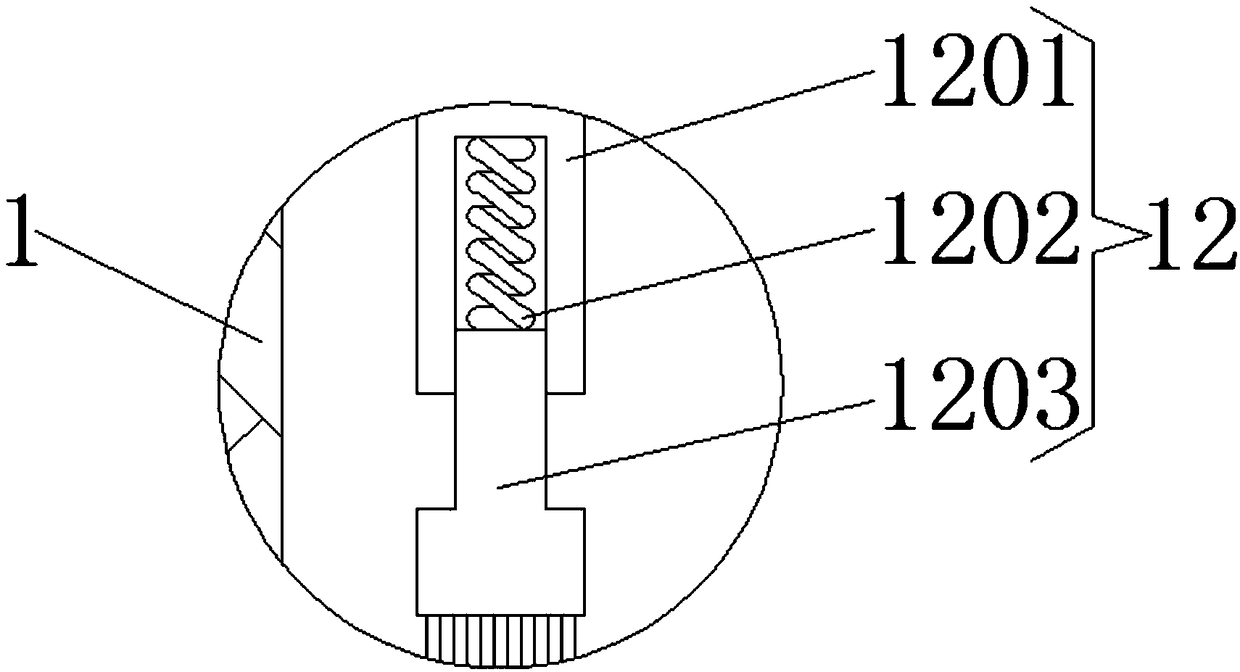

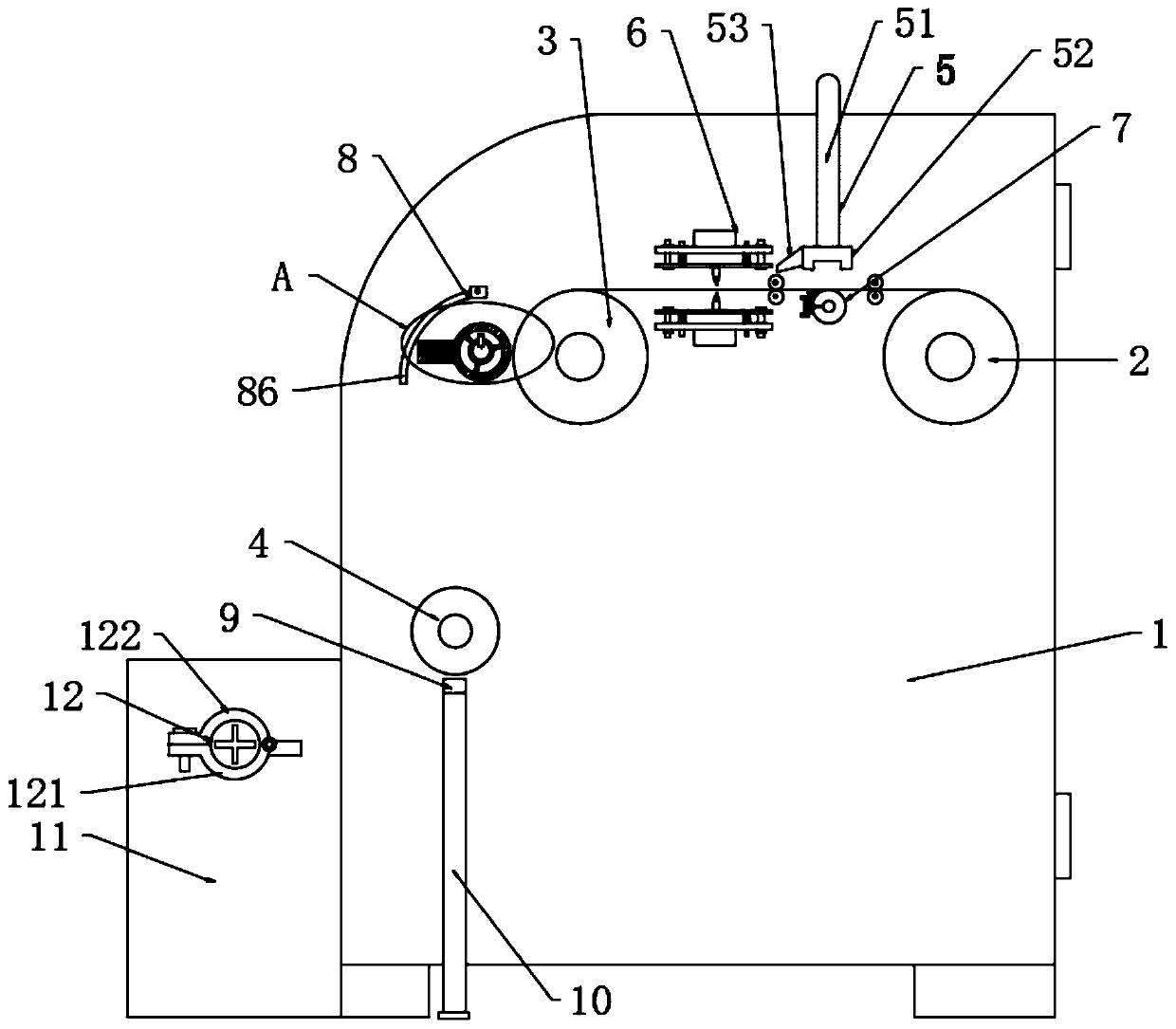

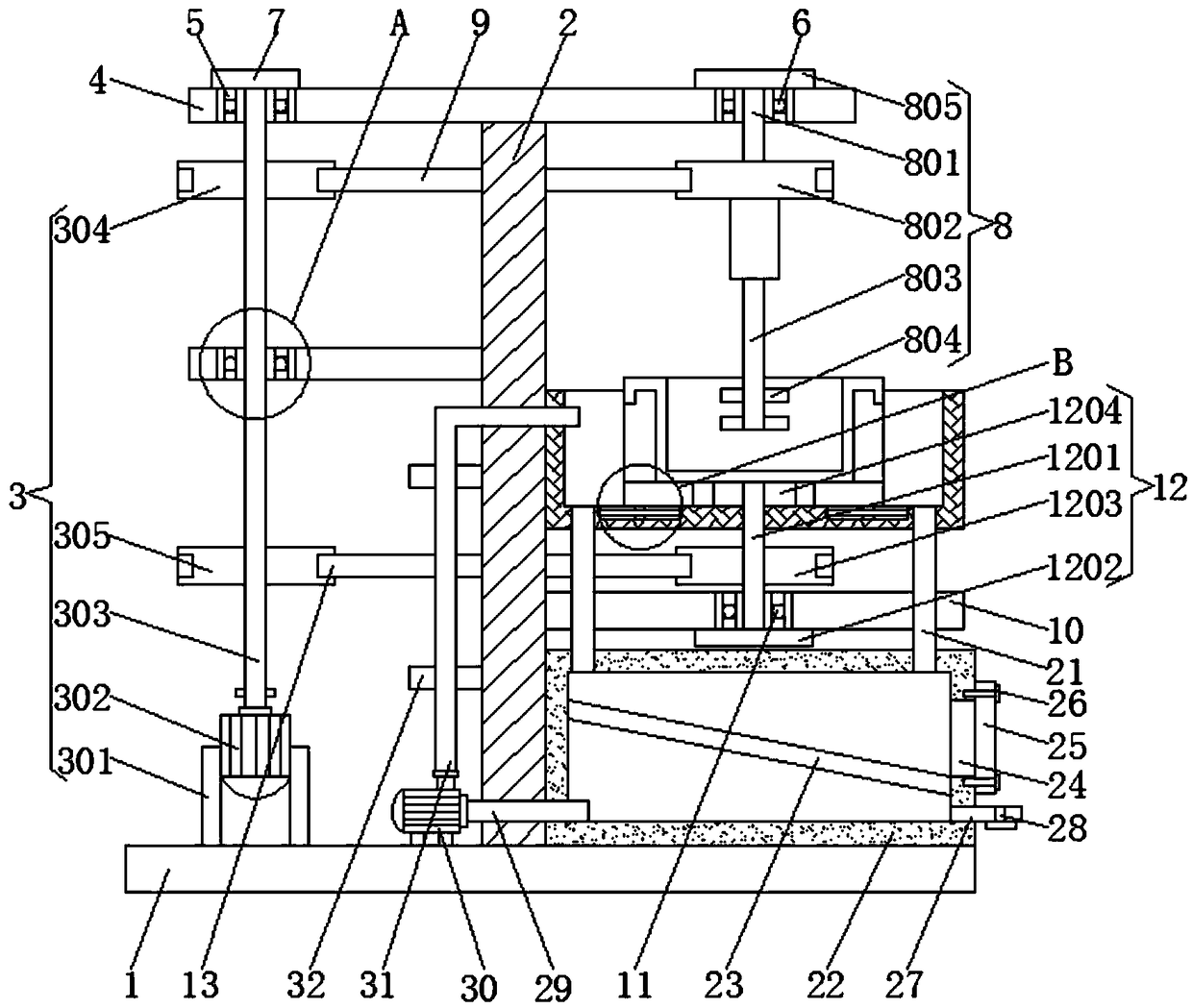

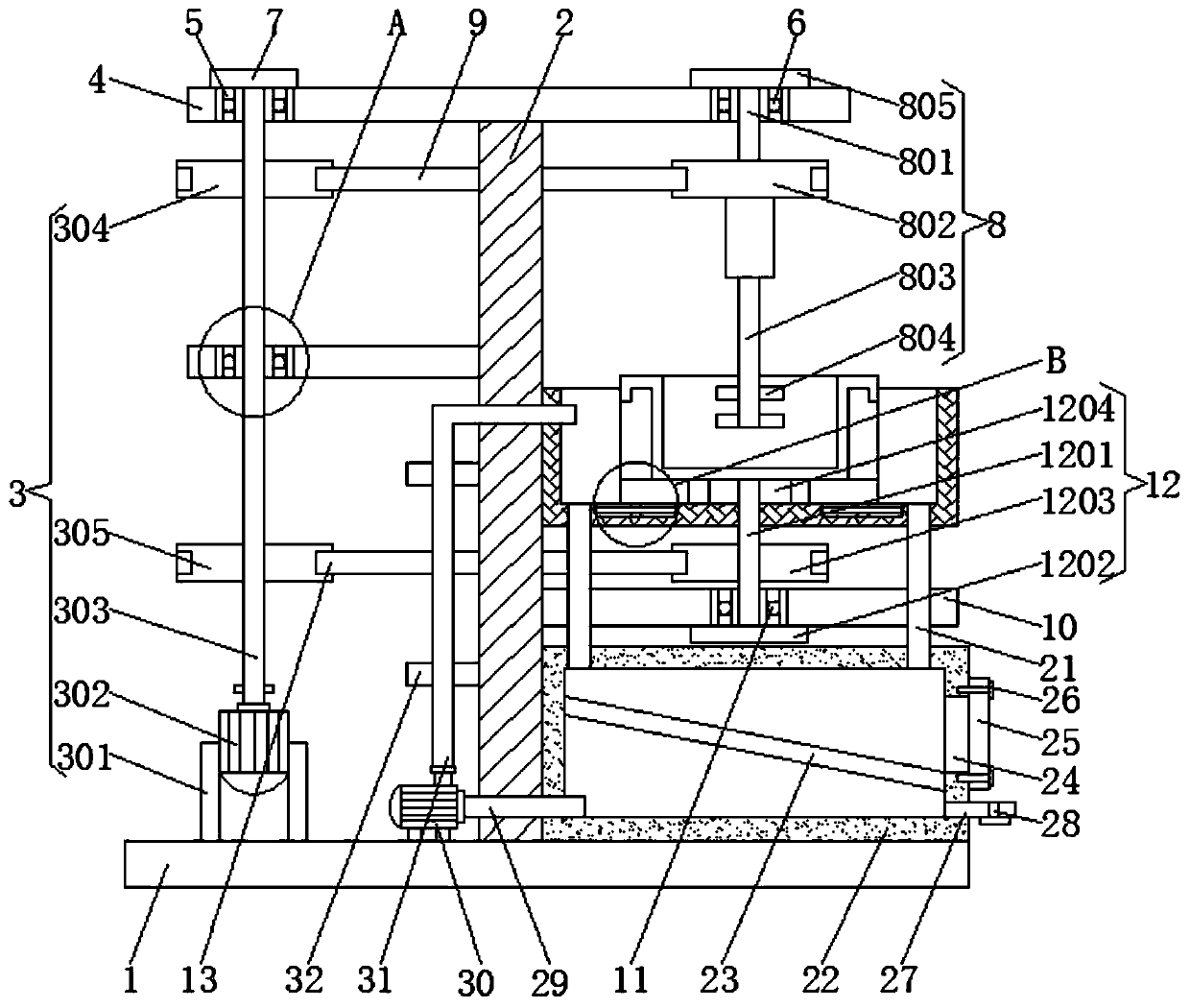

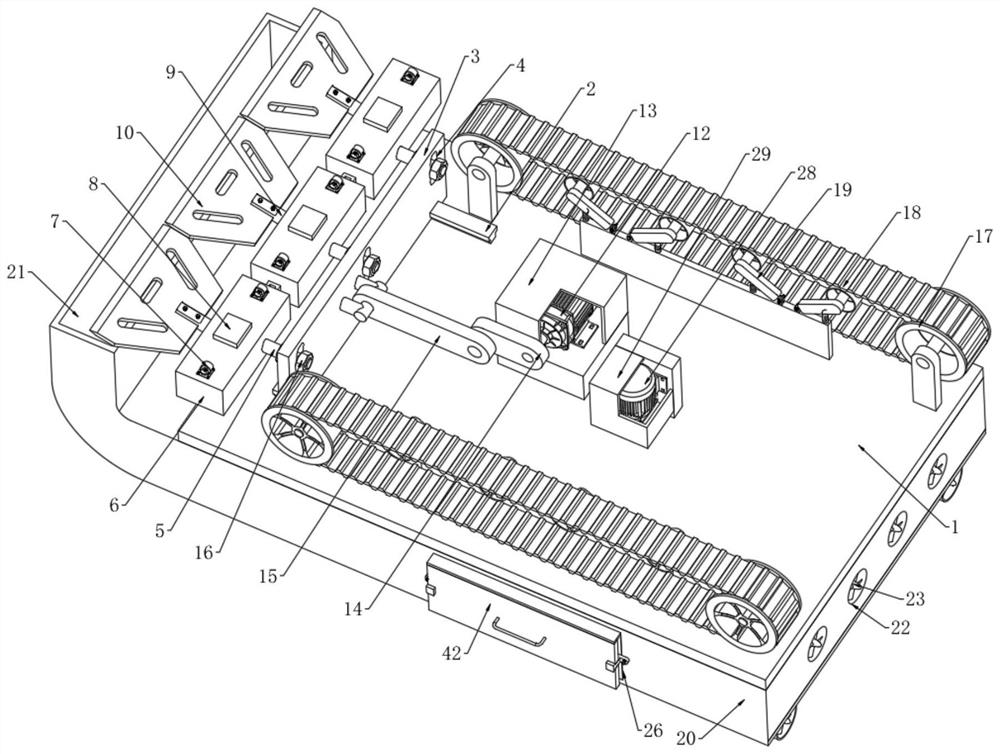

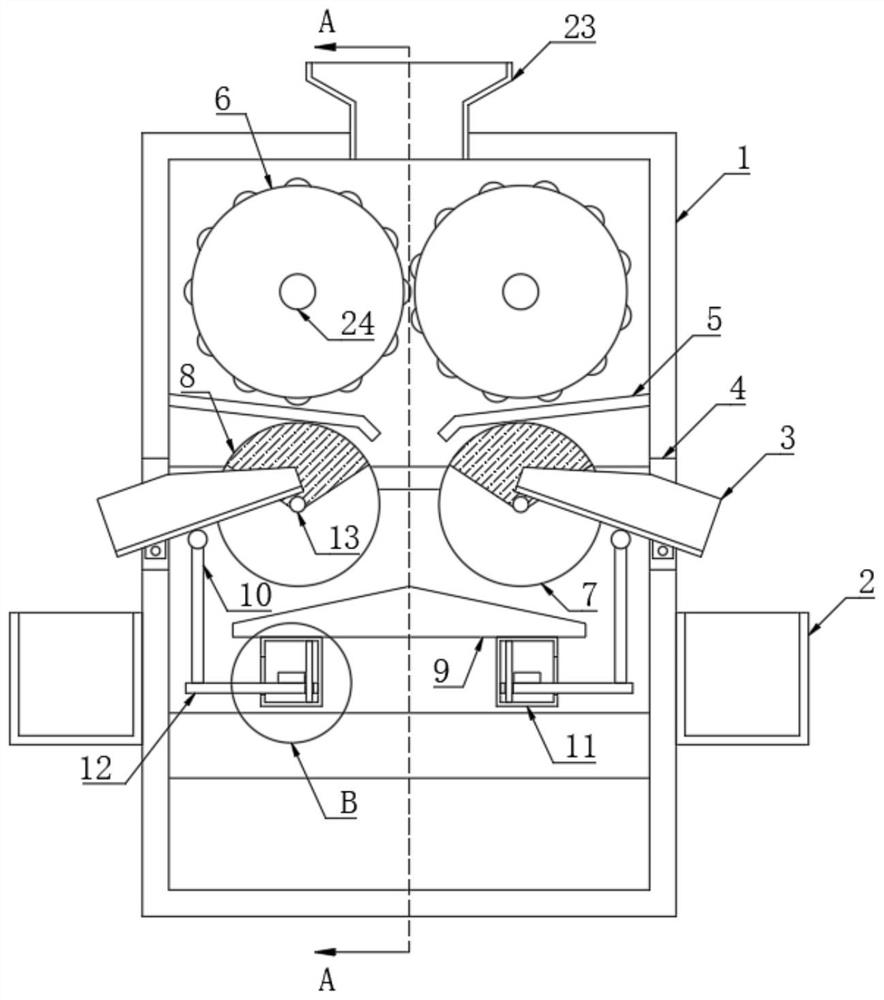

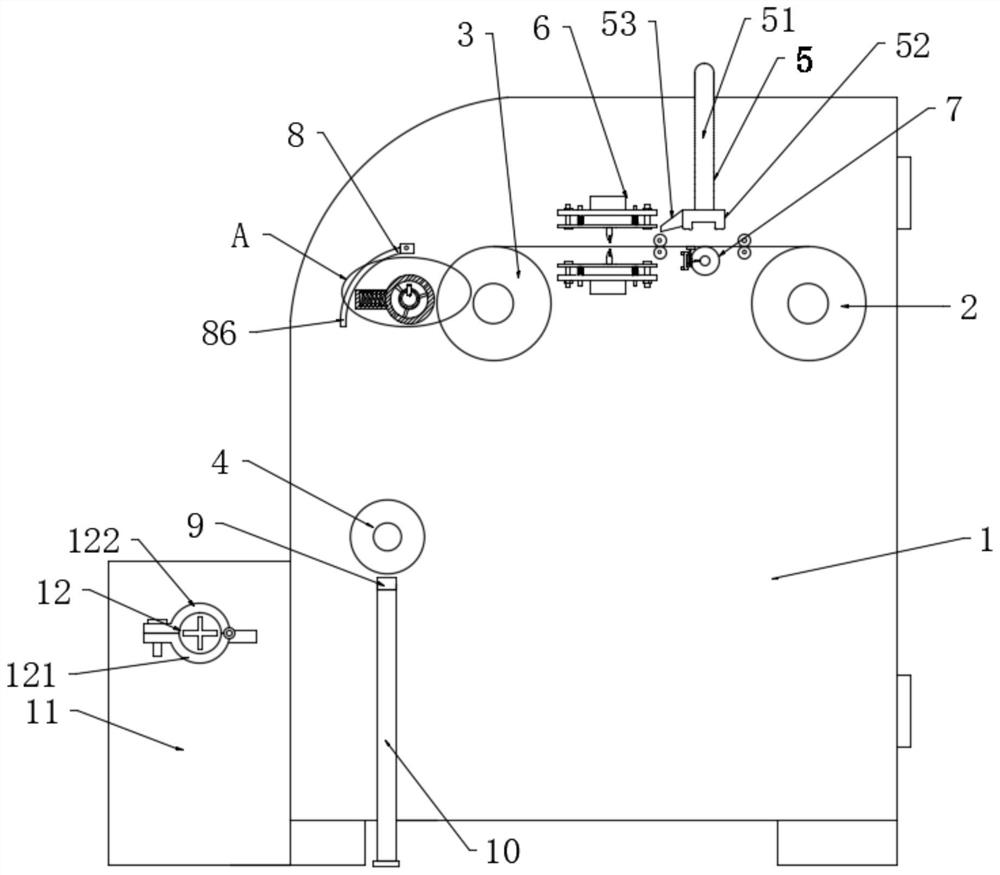

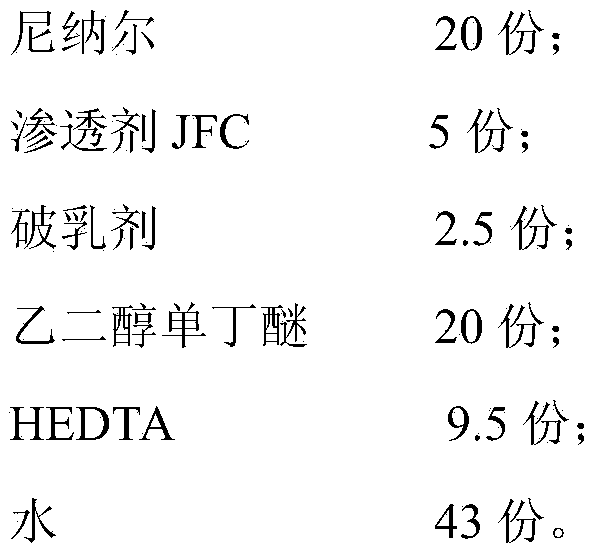

Steel ball impurity removal and classification system

ActiveCN105562351AAchieve grindingAchieve separationCleaning processes and apparatusGradingEngineeringSteel ball

The invention provides a steel ball impurity removal and classification system. The steel ball impurity removal and classification system comprises a machine box, a plurality of first impurity removal mechanisms, a second impurity removal mechanism, a ball classification mechanism and a control mechanism. A ball inlet is formed in the top of the machine box. A ball blocking door, a first driving device, a ball storage barrel and a plurality of ball storage boxes are installed on the machine box. Each first impurity removal mechanism comprises a filter plate, an impurity guiding plate and a vibration motor. The second impurity removal mechanism comprises an impurity removal box, a screw rod and a second driving device. A ball inlet and a ball outlet are formed in the impurity removal box. The ball classification mechanism comprises a plurality of dust isolation plates, a ball guiding plate, a plurality of adjusting rollers and a third driving device. The control mechanism comprises a first sensing device, a second sensing device and a control device. The first driving device, the second driving device, the third driving device, the first sensing device and the second sensing device are all in communication connection with the control device. A first time value is preset to the control device. The steel ball impurity removal and classification system is capable of simultaneously completing impurity removal and classification of steel balls, good in impurity removal effect and high in work efficiency.

Owner:芜湖文达精密机械科技有限公司

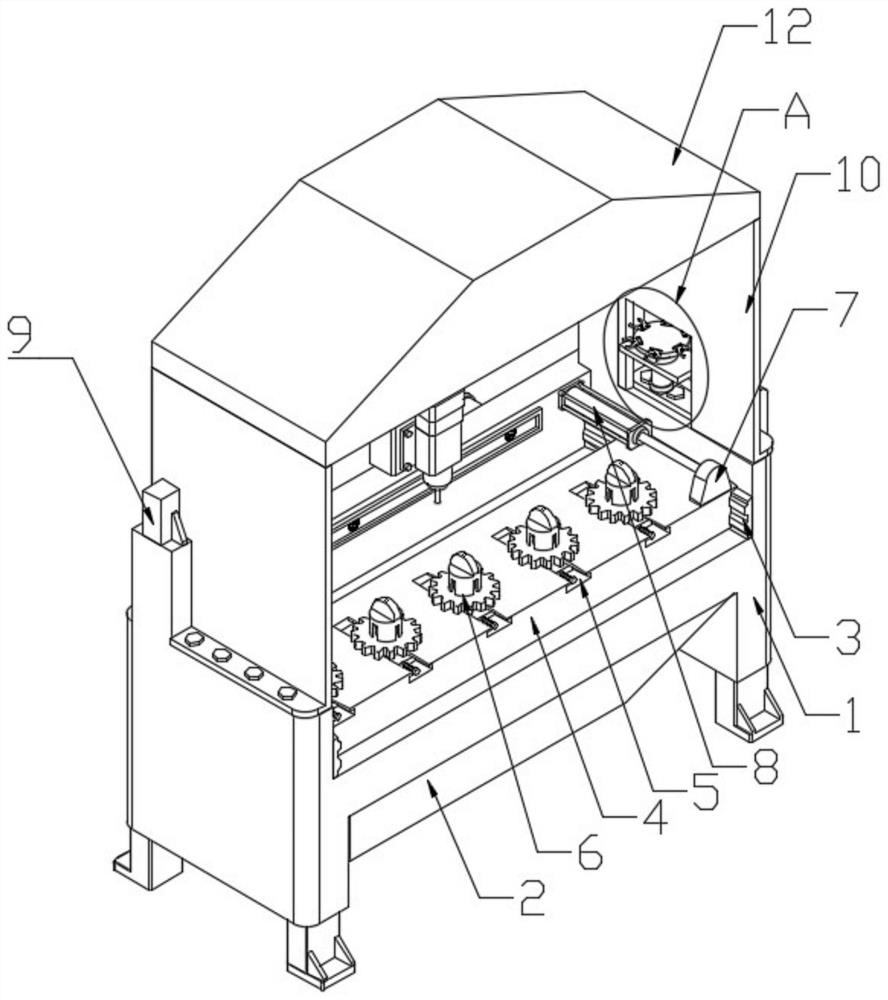

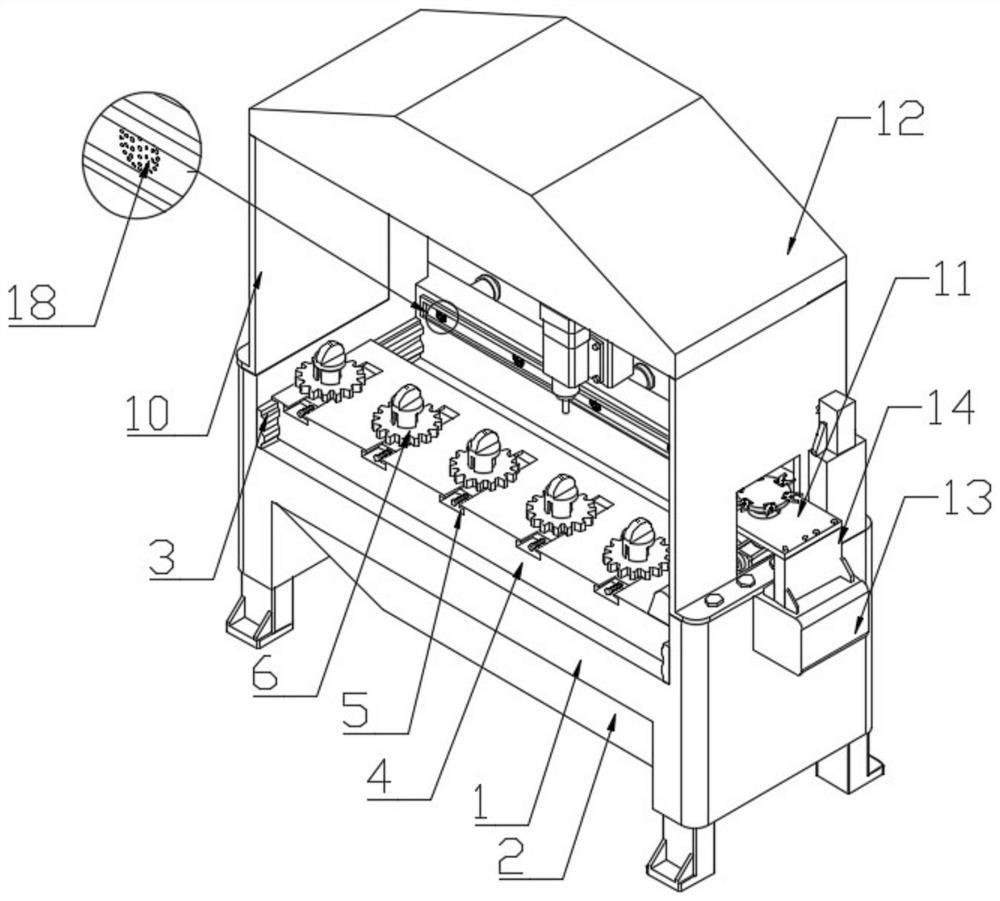

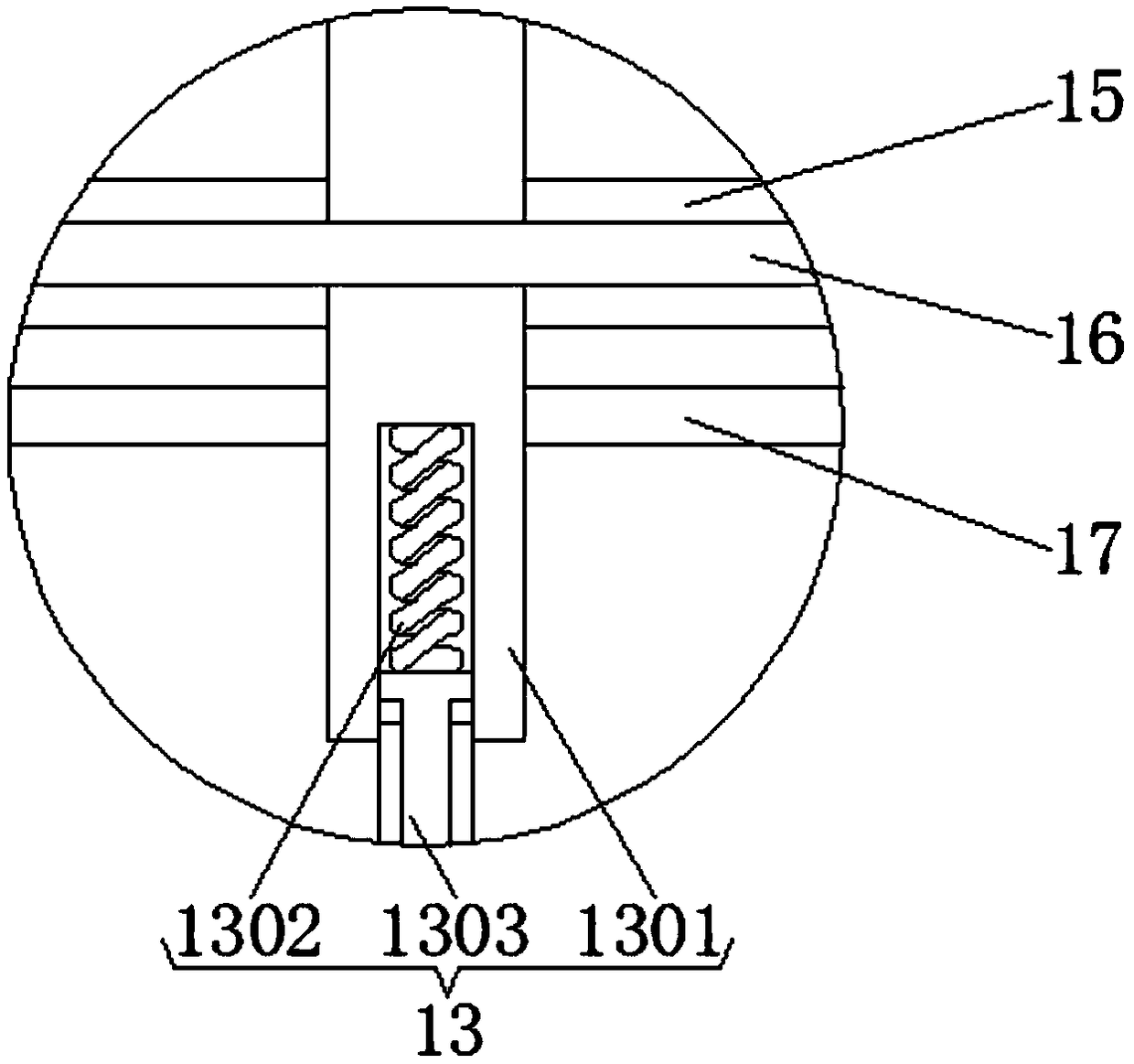

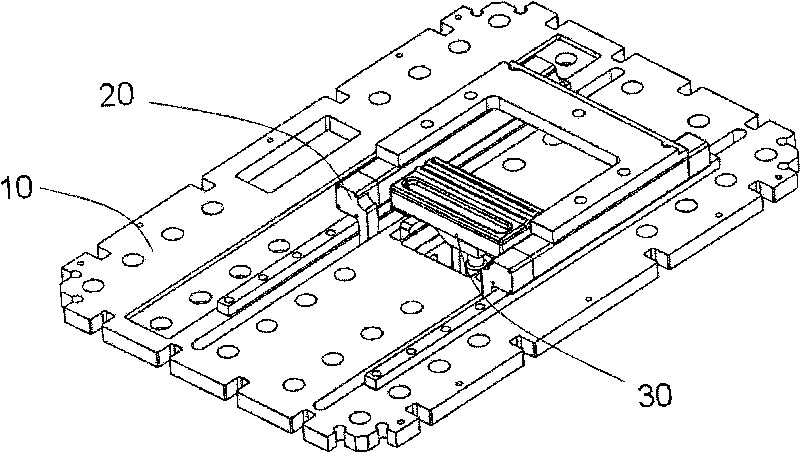

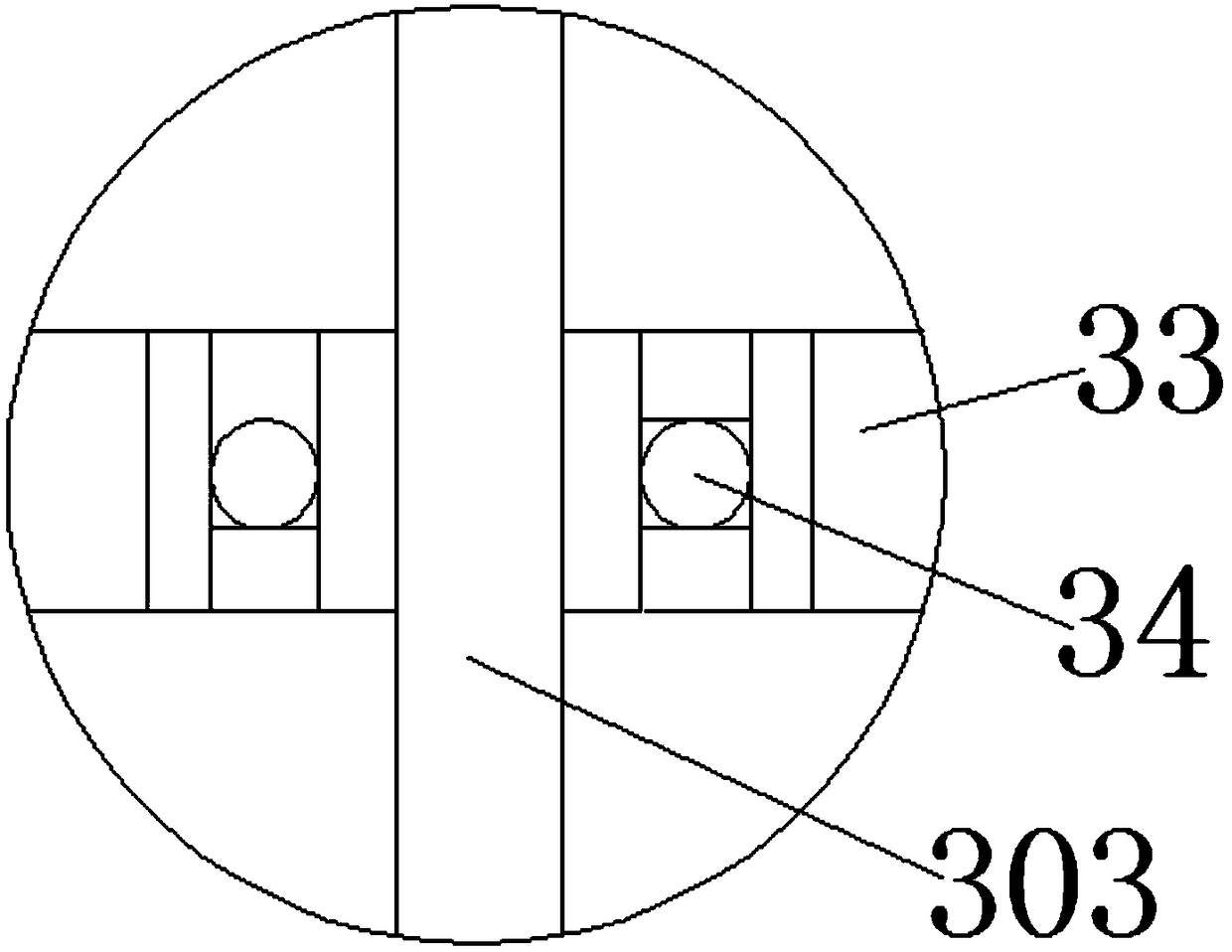

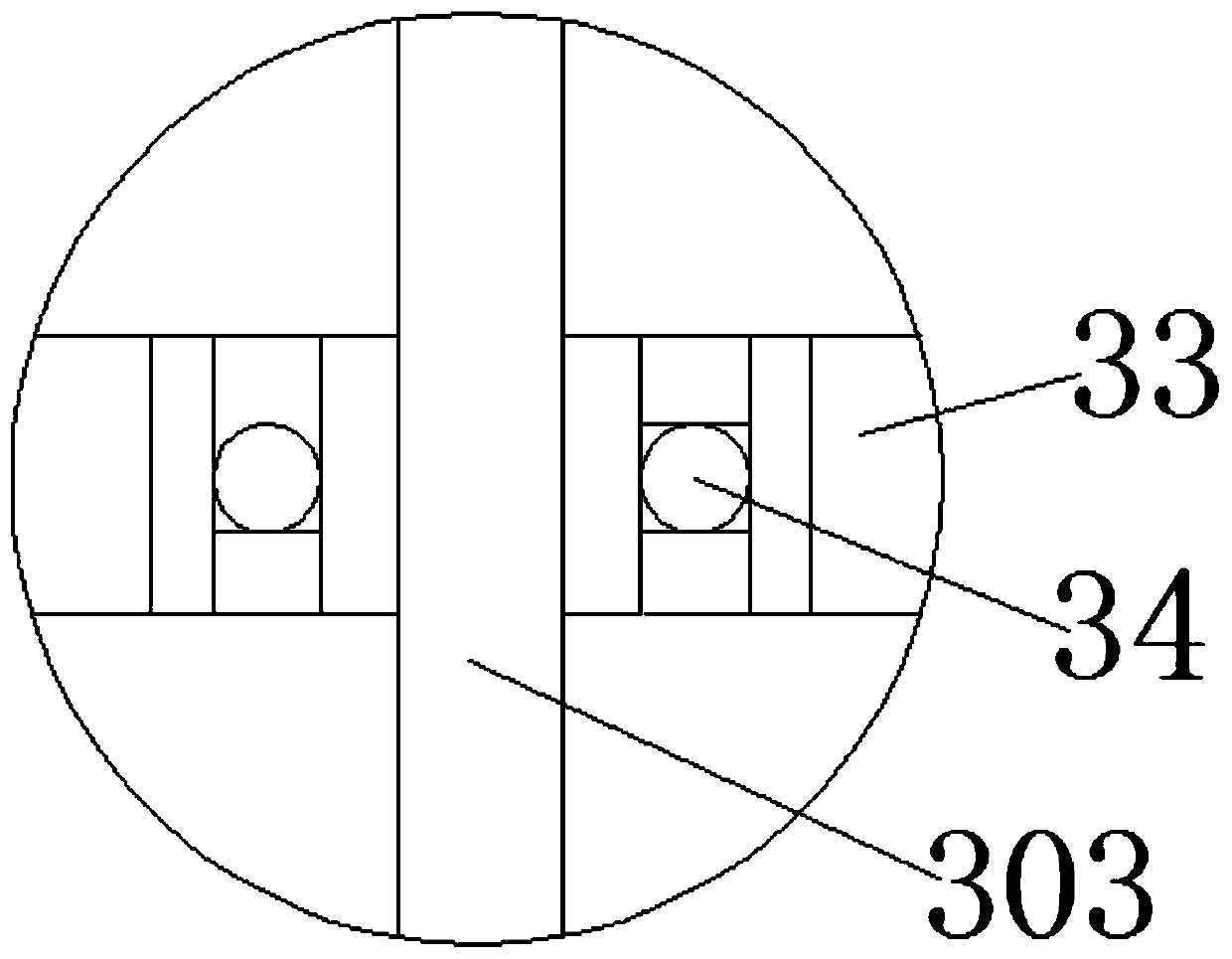

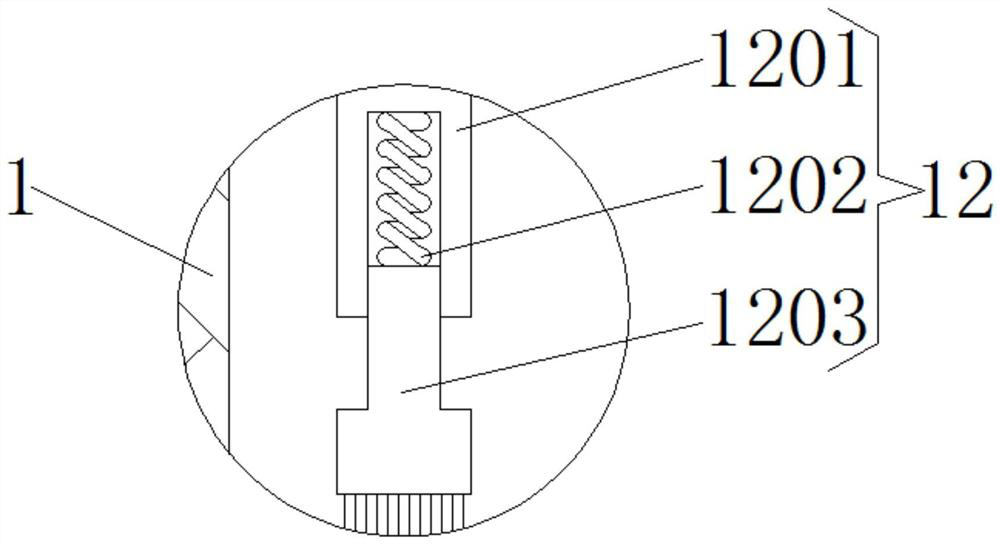

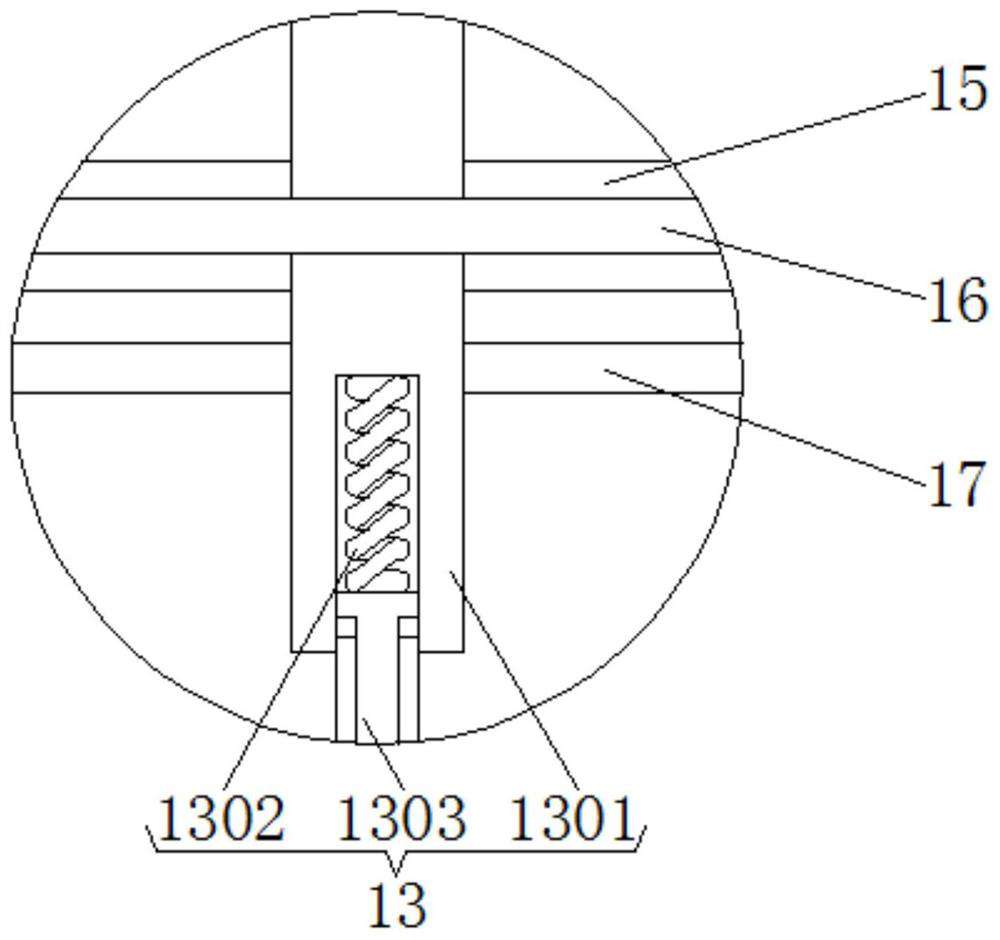

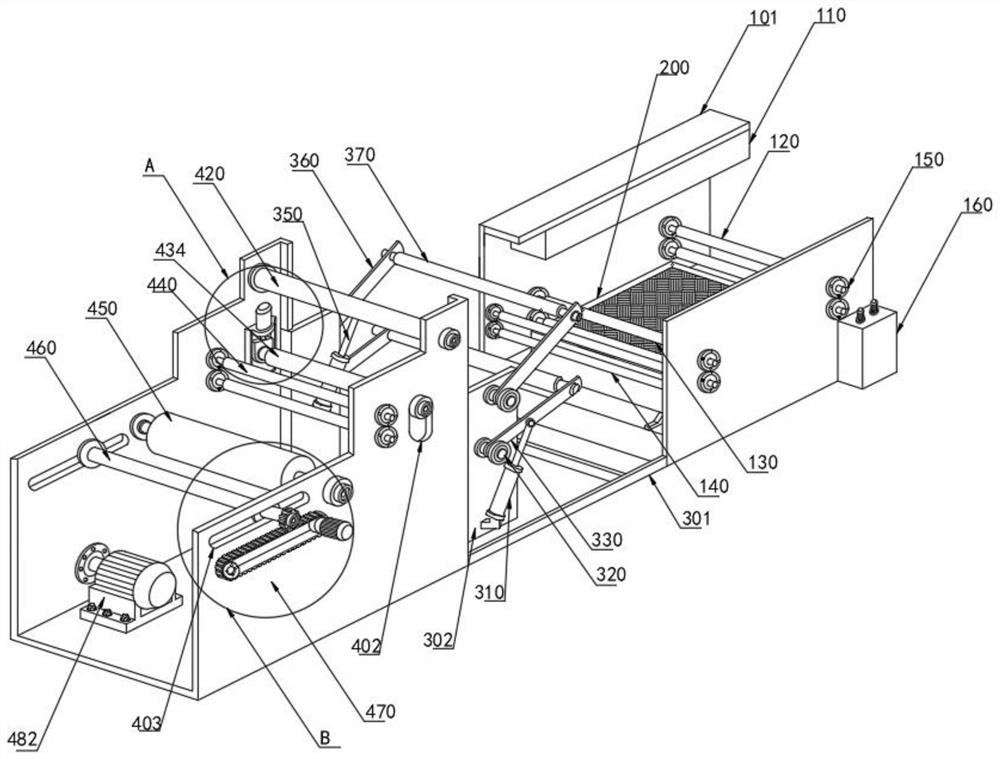

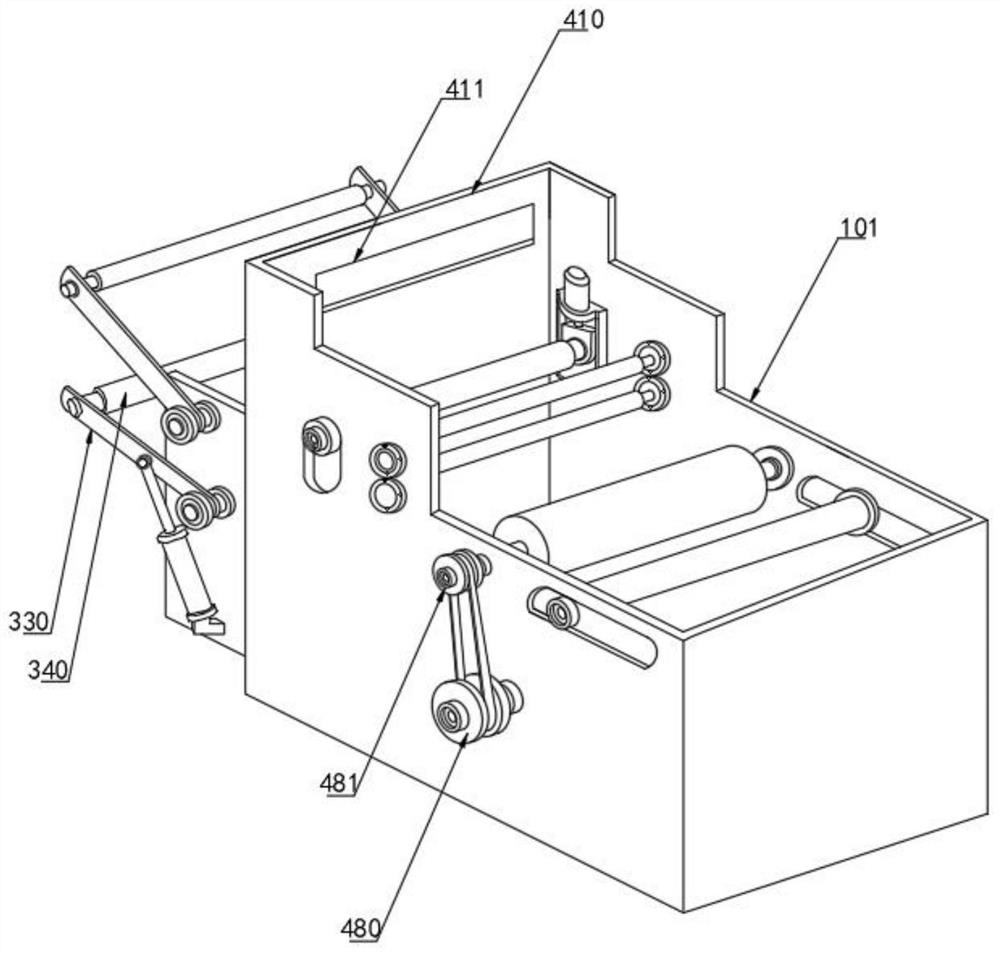

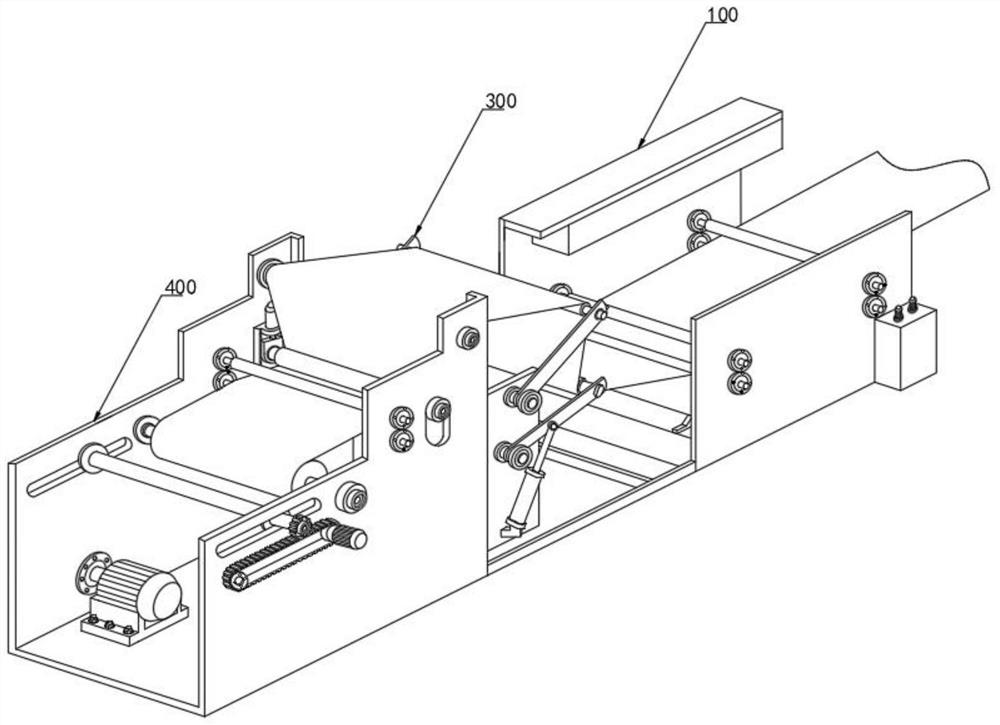

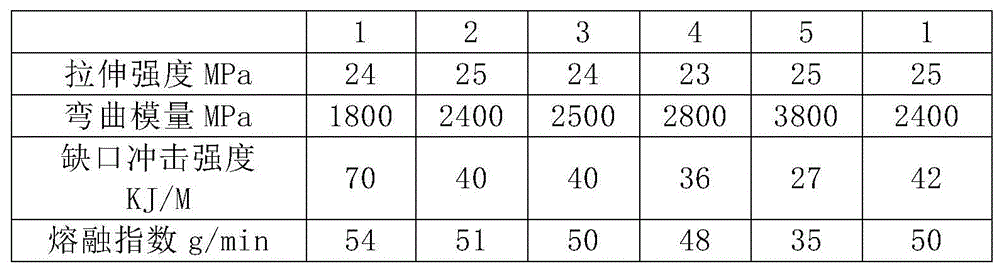

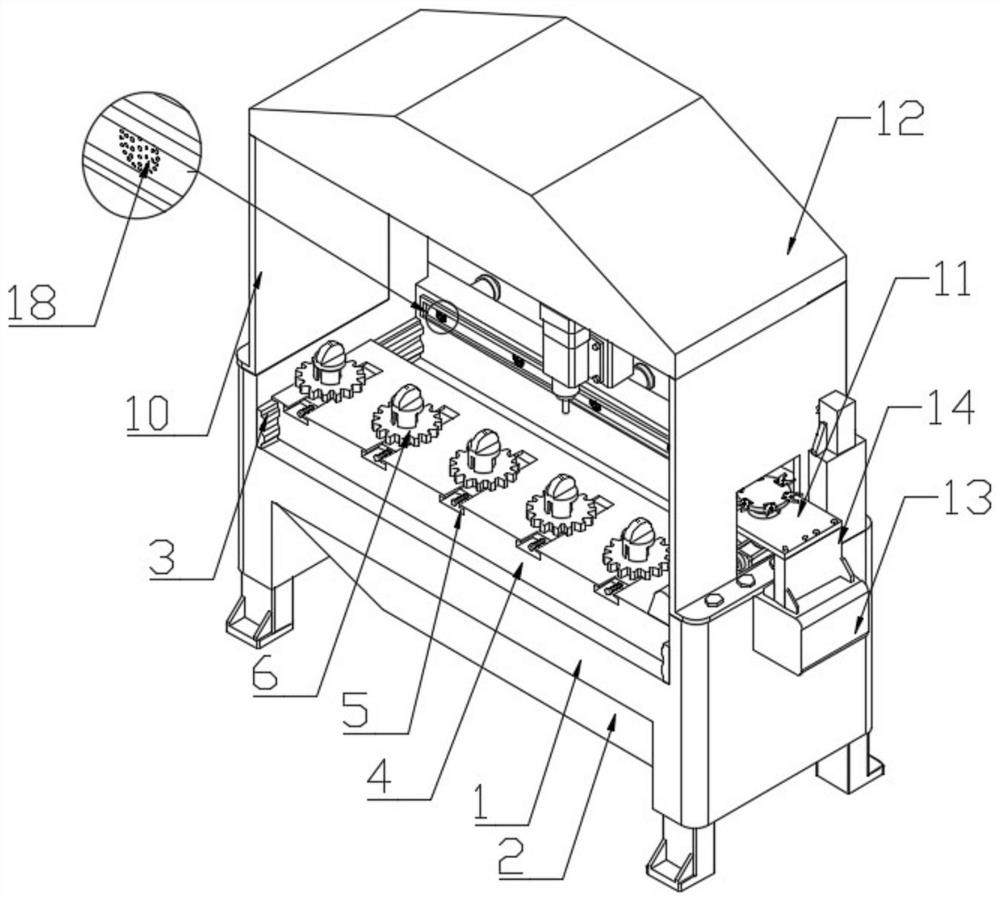

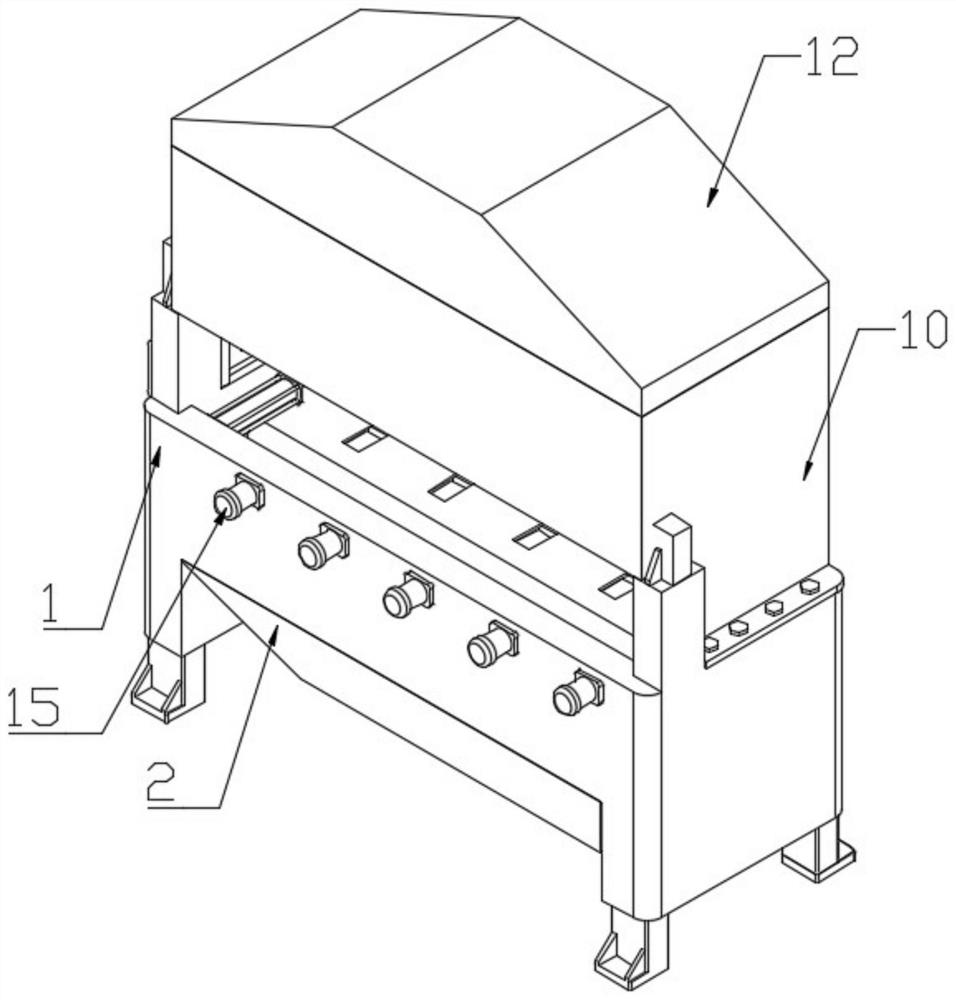

Gear machining multi-station cutting device

ActiveCN113070535AEasy to fixTake advantage ofPositioning apparatusGear-cutting machinesGear wheelMachining

The invention relates to a gear machining multi-station cutting device, relates to the technical field of gear machining. When a gear is fixed, firstly the gear sleeves a fixing cylinder, then a locking assembly penetrates through a lower pressing seat to be in threaded connection with the fixing cylinder, the locking assembly continuously penetrates into the fixing cylinder in a screwing mode, the locking assembly presses a movable supporting arm downwards, at the moment, the movable supporting arm turns over with a fixing shaft as the center and supports the gear, then the lower pressing seat is rotated clockwise, and the gear is tightly clamped between the lower pressing seat and the movable supporting arm. The structure is simple, fixing is convenient, gears of different thicknesses and diameters can be clamped, the application range is wide, and a large amount of clamping time is saved; and after machining is completed, the lower pressing seat is rotated anticlockwise firstly, after the lower pressing seat is not in contact with the gear, the locking assembly is rotated anticlockwise, the locking assembly moves upwards, the movable supporting arm is jacked up through a spring, and at the moment, the gear can be detached.

Owner:JIANGSU AIRSHIP GEAR

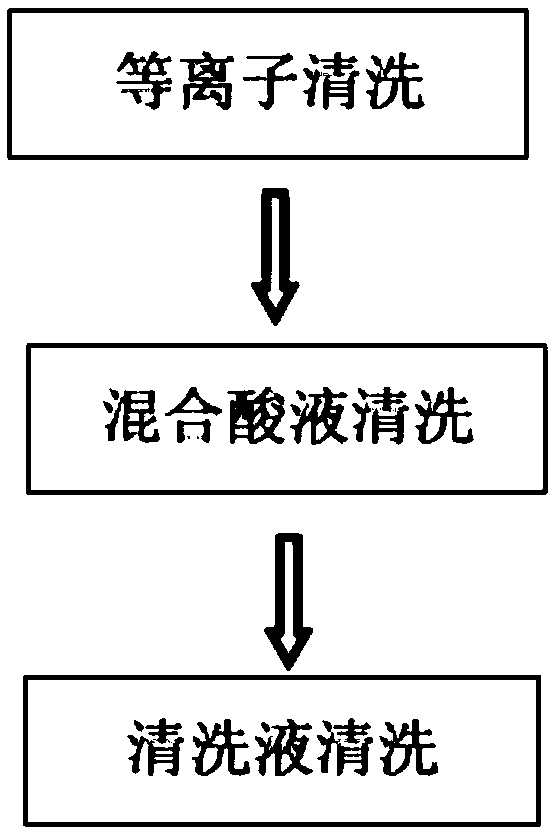

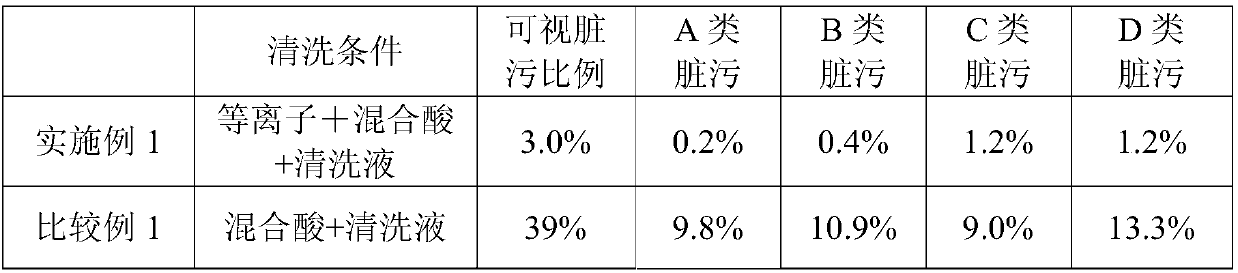

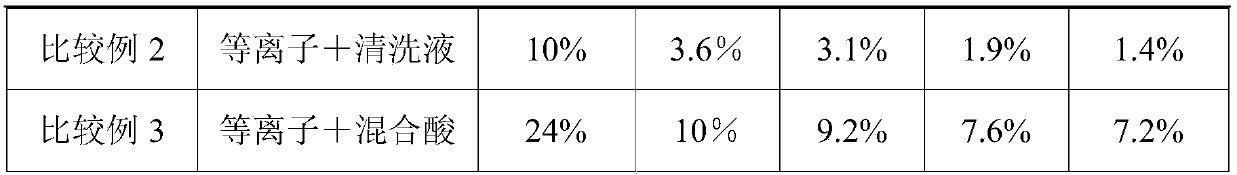

Sapphire lens cleaning method

InactiveCN110449397AReduce usageSimple processInorganic/elemental detergent compounding agentsLens cleaning compositionsSodium metasilicateStrong acids

The invention discloses a sapphire lens cleaning method. The sapphire lens cleaning method comprises the following steps of plasma cleaning, mixed acid solution cleaning and cleaning fluid cleaning. According to the sapphire lens cleaning method, the cleaning modes such as plasma cleaning is introduced to bear the cleaning task of most impurities and dirt of a sapphire lens, and the surface of sapphire is prevented from adsorbing the impurities and dirt again; then, cleaning is carried out in a mixed liquid acid solution of hydrogen peroxide and concentrated sulfuric acid, and then deionized water cleaning is carried out so as to further remove the dirty and impurities; and then cleaning and drying the sapphire lens in an ultrasonic container filled with cleaning liquid so as to thoroughlyremove the residual impurities and dirt, wherein the cleaning fluid comprises the components of a nonionic surfactant, carboxymethyl cellulose, sodium metasilicate, sodium hydroxide, a perfluoropolyether-based surfactant and deionized water. According to the cleaning method, a cleaning agent is reasonably selected, and the cleaning steps are reasonably designed, so that the use of strong acid anda strong oxidant is reduced; and the method is simple in technological process, efficient and environment-friendly, the operation method is easy to master, the production is safe, and the automationimplementation of a production line is facilitated.

Owner:LENS TECH

Peach cleaning fuzz removing device based on elastic squeezing and water recycling

InactiveCN108814347ASolve the problem that the peaches cannot be cleanedEasy to recycleKitchen equipmentTransmission beltEngineering

The invention discloses a peach cleaning fuzz removing device based on elastic squeezing and water recycling, and relates to the technical field of fruit cleaning. The peach cleaning fuzz removing device based on elastic squeezing and water recycling comprises a water collecting device, a supporting block is fixedly connected to the bottom of the left side of the water collecting device, a water pump is fixedly connected to the upper surface of the supporting block, a first pipeline is fixedly communicated with the water inlet end of the water pump, and the surface of the first pipeline is fixedly communicated with the left side of the water collecting device. According to the peach cleaning fuzz removing device based on elastic squeezing and water recycling, a rotating device is rotated to make peaches rotate, a first threaded rod rotates through a rotating disc and a transmission belt, a telescopic device moves left and right under the effect of the first threaded rod, and peaches are subjected to fuzz removing through a fuzz removing device; when cleaning peaches, a user does not need to touch the peaches by hand, and thus the problem that people allergic to peaches cannot cleanpeaches is effectively solved.

Owner:陈山

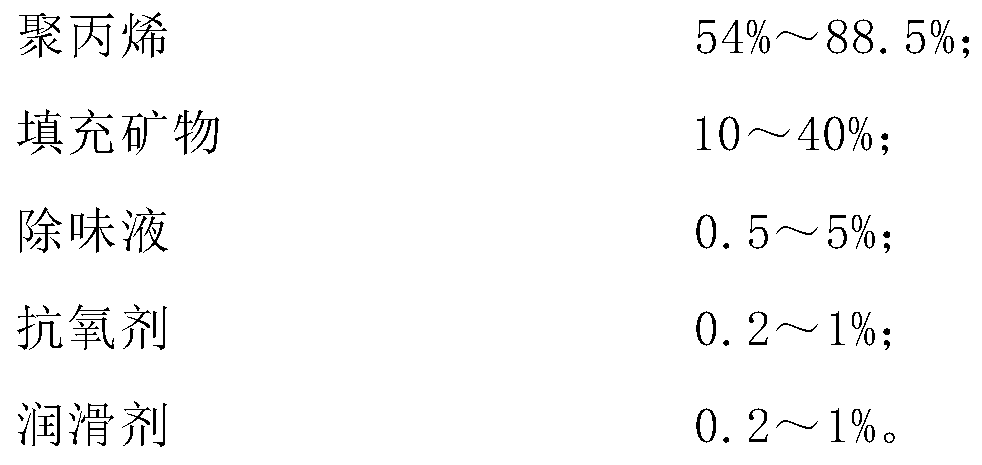

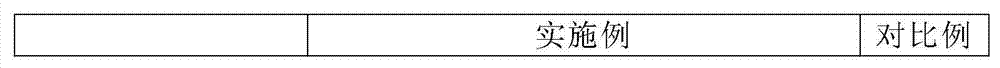

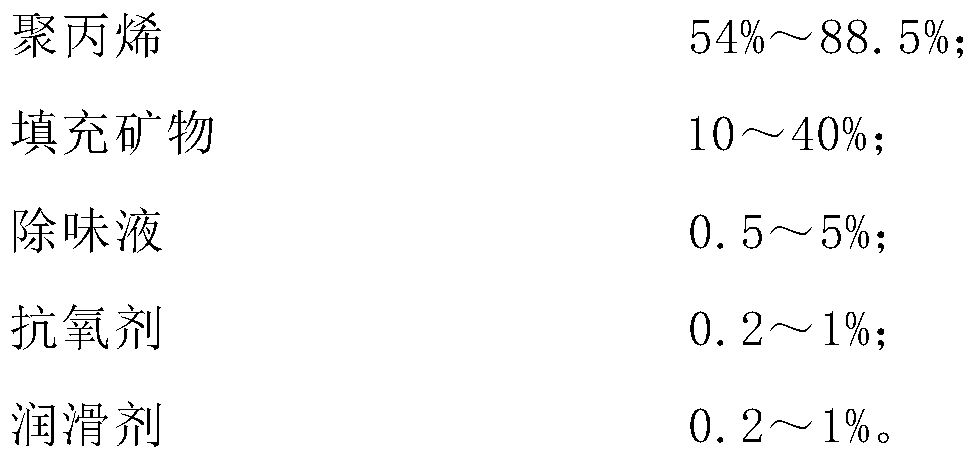

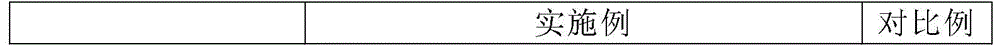

Low-odor mineral reinforced polypropylene composite material and preparation method thereof

The invention discloses low-odor mineral reinforced polypropylene composite material and a preparation method thereof. The material is prepared from the following components in percentage by weight: 54-88.5% of polypropylene, 10-40% of filling minerals, 0.5-5% of an odor removing liquid, 0.2-1% of an antioxidant and 0.2-1% of a lubricant. The preparation method comprises the following steps: mixing the raw materials except the odor removing liquid in a high-speed mixer and discharging; putting the mixed raw materials into a main feeding opening of a twin-screw extruder; metering and inputting the odor removing liquid from a side feeding opening by virtue of a centrifugal pump; vacuumizing; carrying out melt extrusion and prilling by virtue of the twin-screw extruder to prepare the low-odor mineral reinforced polypropylene composite material. Compared with the prior art, the low-odor mineral reinforced polypropylene composite material prepared by the reparation method provided by the invention is excellent in mechanical property, low in VOC and environment-friendly and can be widely used in the fields of automobiles, household appliances, sports articles and the like.

Owner:上海日之升科技有限公司

Battery silicon wafer anticorrosive cleaning agent

InactiveCN104928060AExcellent decontaminationNo irritating smellInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIonSodium carboxymethylcellulose

The invention discloses a battery silicon wafer anticorrosive cleaning agent composed of the raw materials of, by weight, 0.5-2.5% of potassium hydroxide, 4-8% of fatty alcohol polyoxyethylene (7) ether, 0.4-0.8% of ethylene glycol butyl ether, 0.4-0.8% of perfluoroalkyl polysorbate alcohol, 0.2-1% of a complex, 2-4% of tetramethyl ammonium hydroxide, 0.1-0.3% of sodium carboxymethylcellulose, and balance of deionized water. The battery silicon wafer anticorrosive cleaning agent provided by the invention has good decontamination and cleaning performances, and has no irritating odor. With the cleaning agent, silicon carbide and the like can be effectively prevented from being adsorbed on the surface of silicon wafers again, and secondary pollution is reduced. The cleaning agent causes low corrosion to the silicon wafer, and is suitable for photovoltaic and semiconductor silicon wafer cleaning. The cleaning agent is especially suitable for solar wafer cleaning.

Owner:宁波高新区卓尔化工科技有限公司

Cloth surface debris treatment roller for textile machine

ActiveCN111041805AAchieve clearingAdjustable depth of contactMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a cloth surface debris treatment roller for a textile machine. The cloth surface debris treatment roller comprises a side plate, wherein a cloth feeding roller, a traction roller and a guide roller are rotationally mounted on the side plate; a recycling mechanism is fixedly mounted on the side plate; a scraping mechanism is fixedly mounted on the side plate; an ironing mechanism is mounted on the side plate; a grounding rod is fixedly mounted on the side plate; a conductive sheet is fixedly connected to the grounding rod; a pedestal is fixedly mounted on the side plate;a collecting mechanism is connected to the pedestal; a debris scraping and recycling mechanism is arranged in the collecting mechanism; when cloth is continuously pulled for collection, a scraper isin contact with the surface of the cloth to scrape debris; the recycling mechanism is connected with a negative pressure dust suction device to recycle the debris through wind power; and the scrapingmechanism comprises an adjusting device, so that the contact depth of the scraper and the cloth is adjustable, the cloth surface debris treatment roller is suitable for cloth with different thicknesses, and the debris can be scraped to the maximum extent while the cloth is prevented from being damaged.

Owner:温州派瑞机械科技有限公司

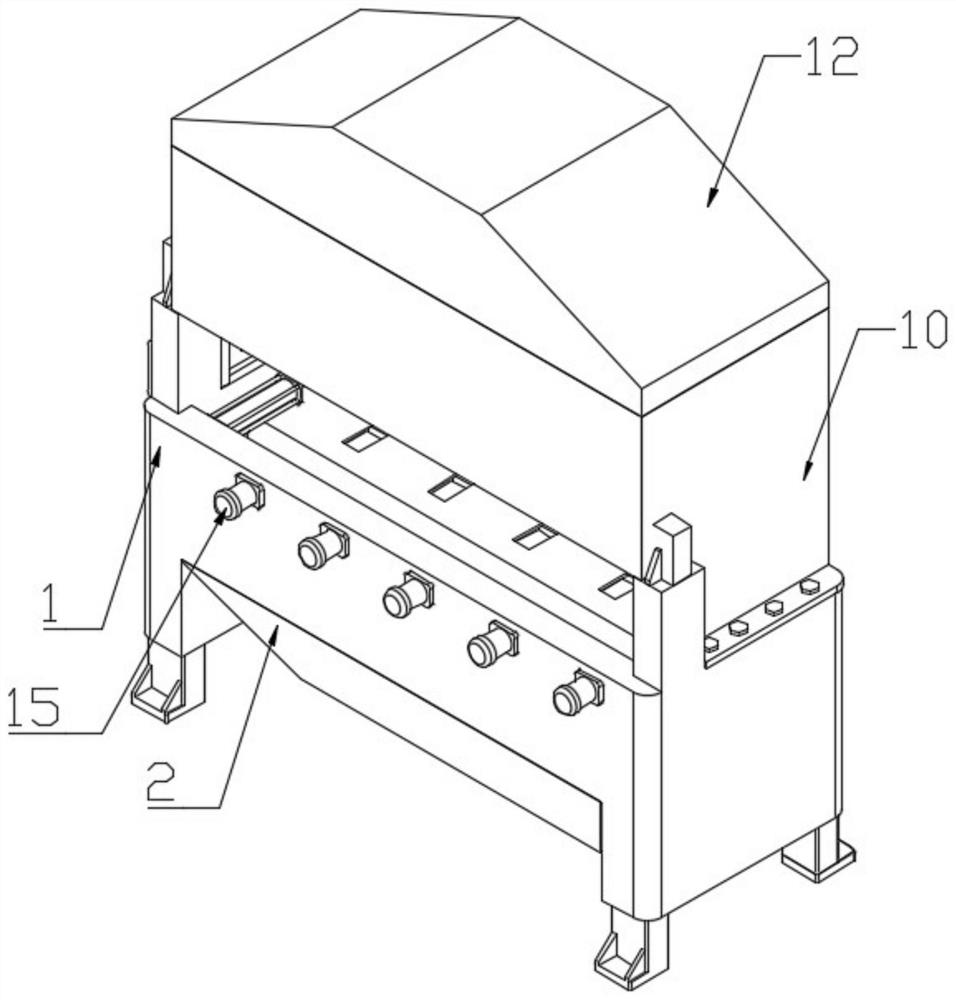

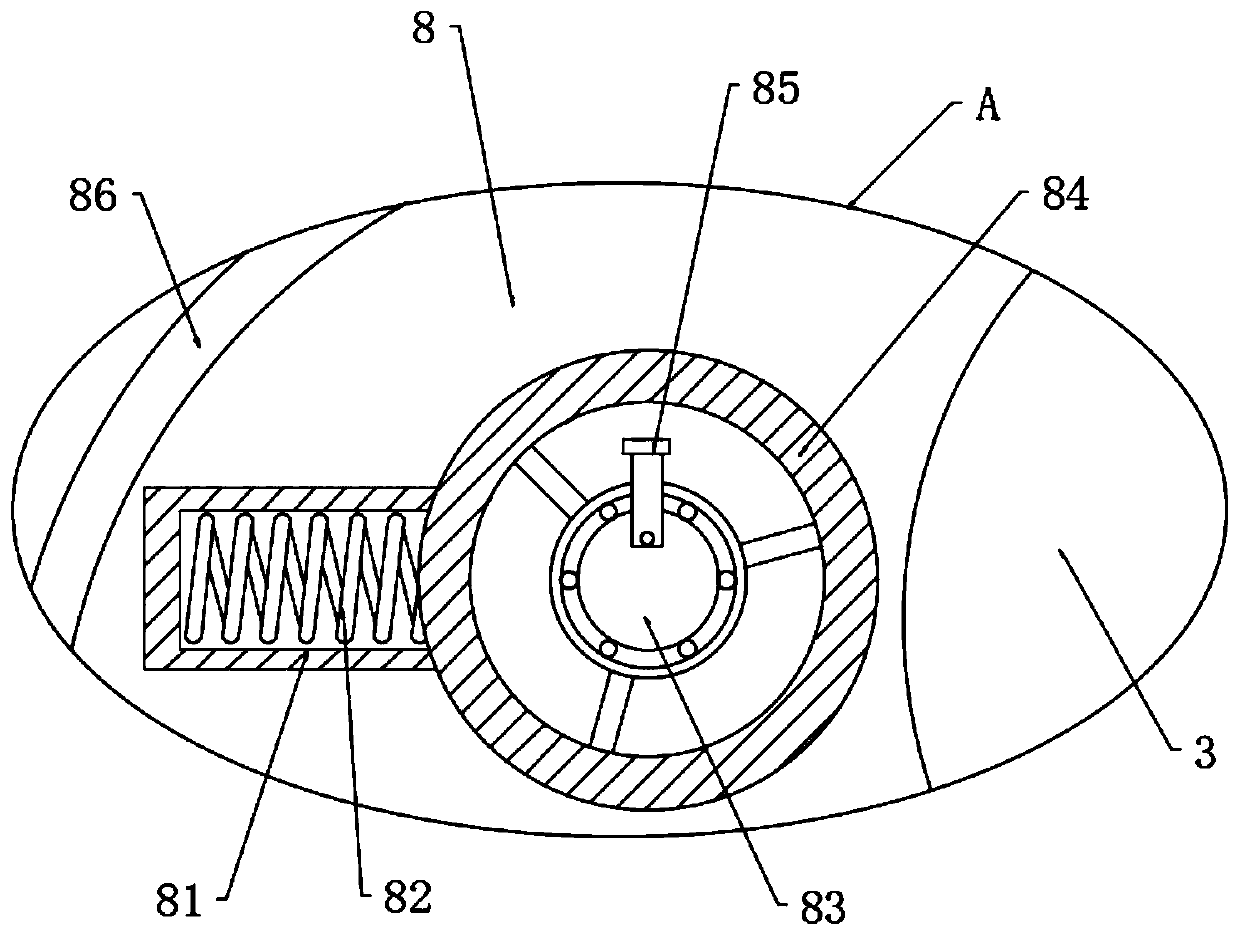

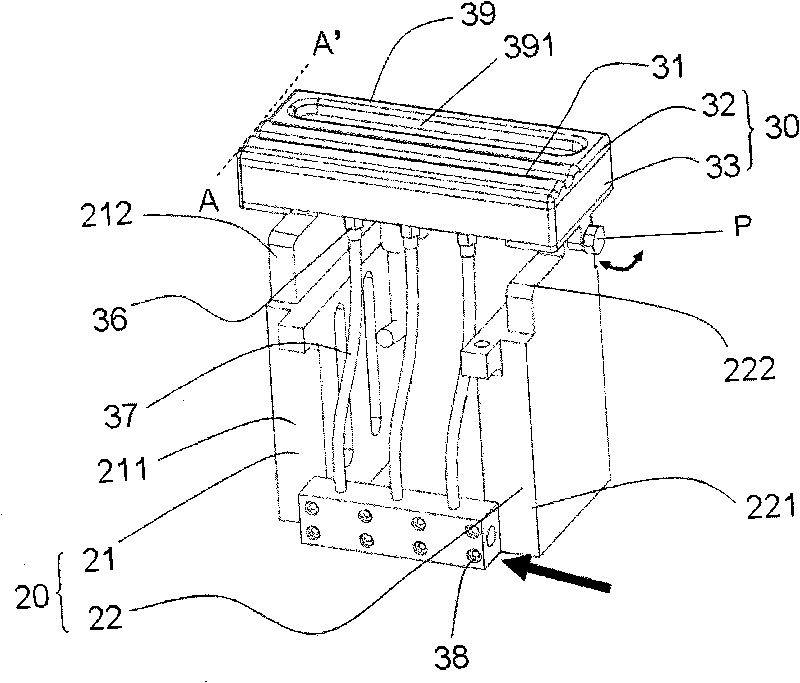

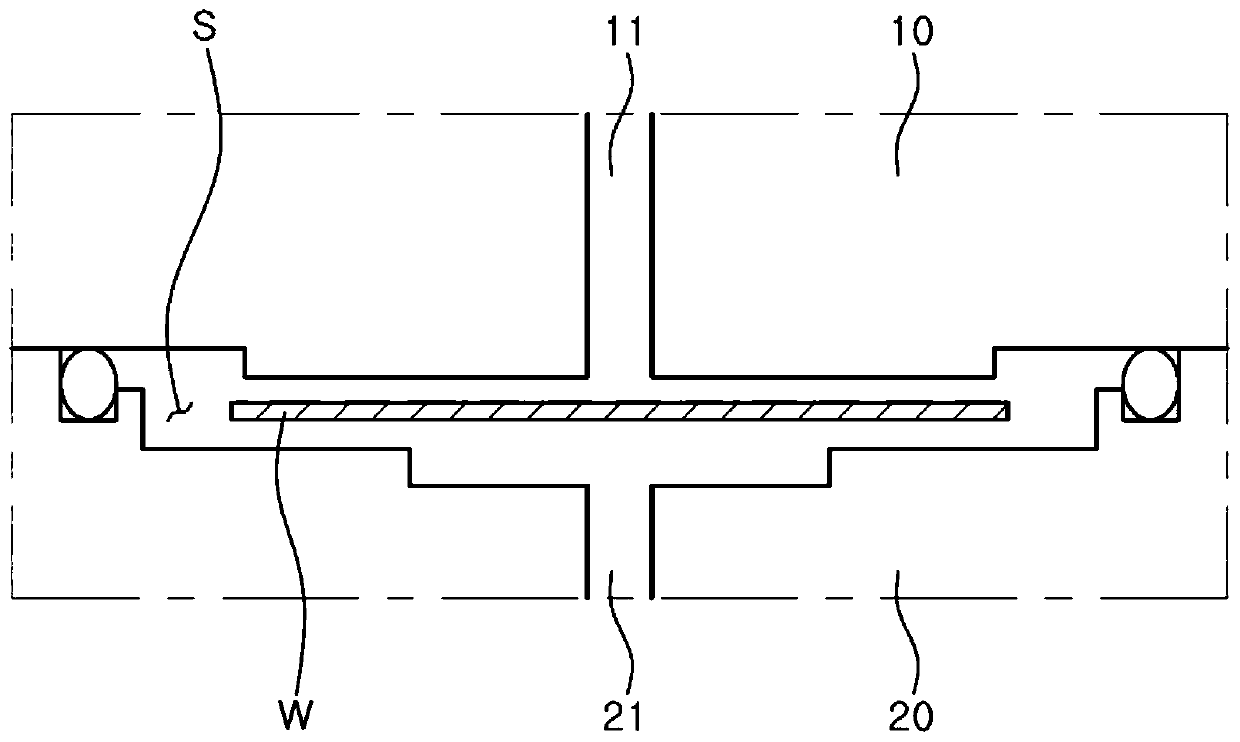

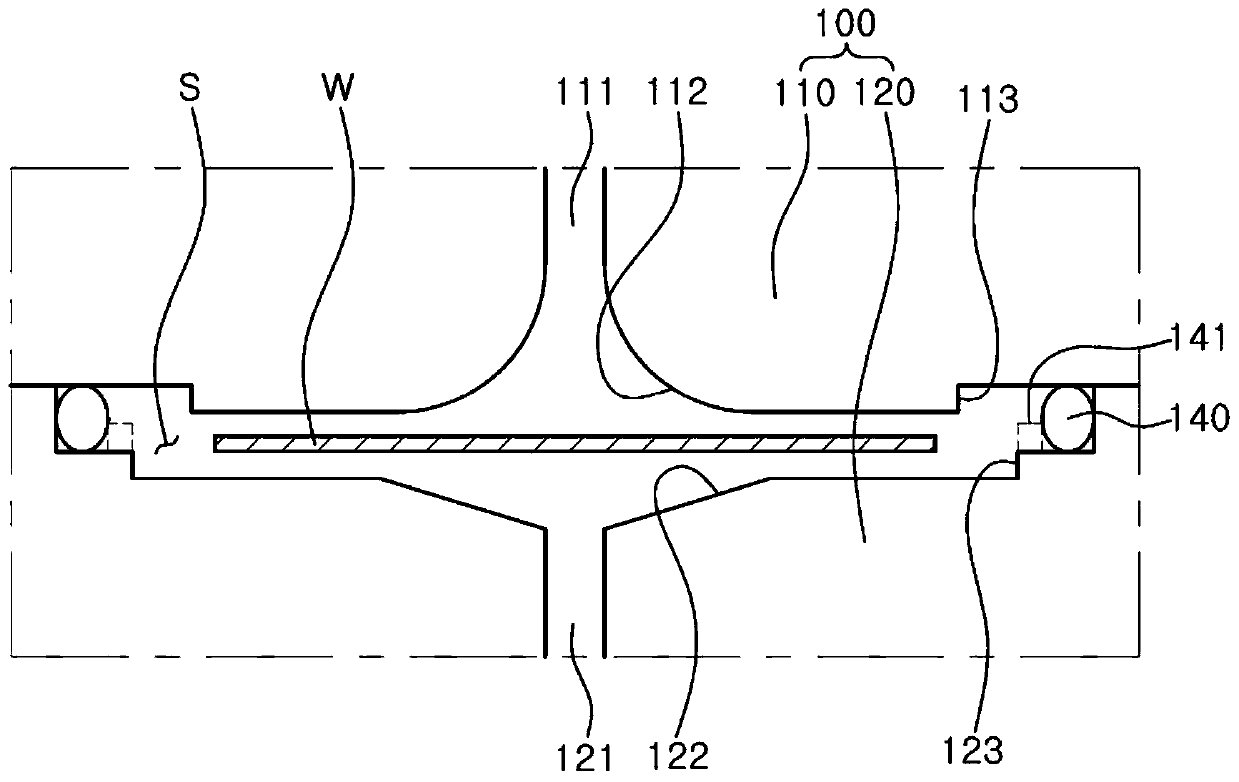

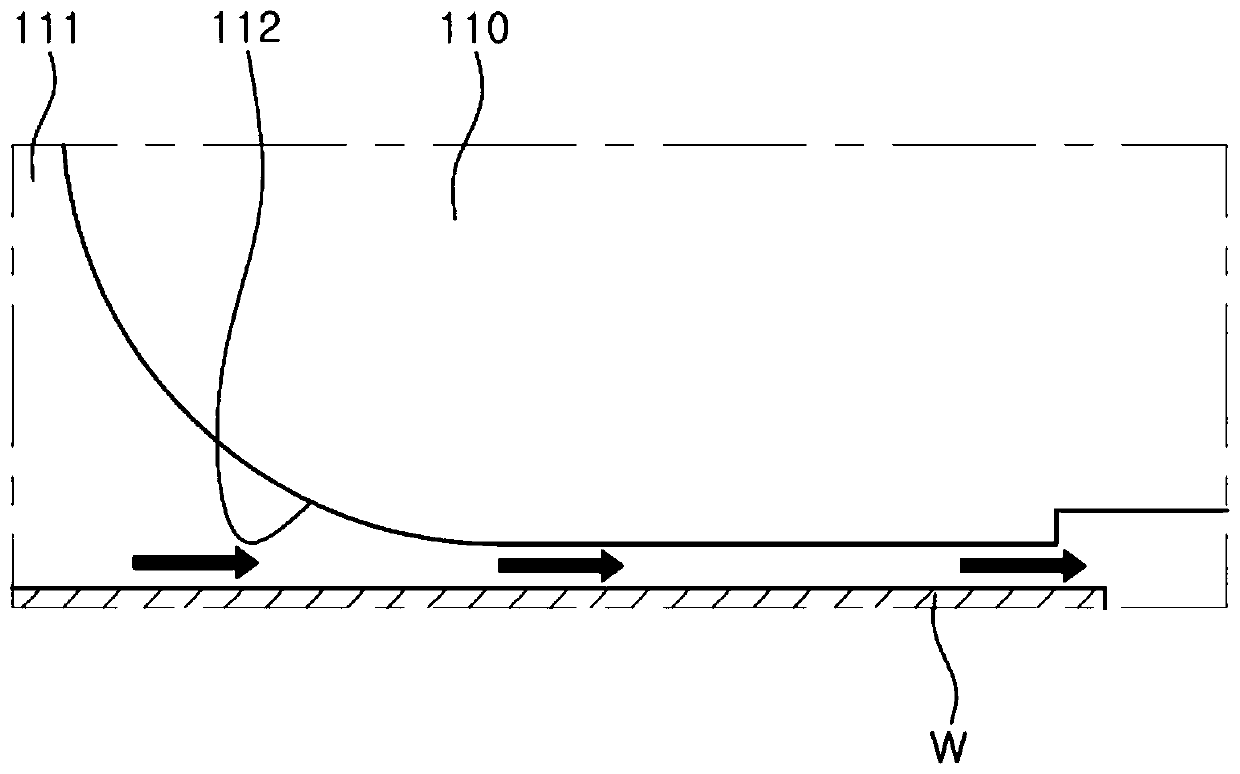

Cleaning device for semiconductor base material

ActiveCN101740325AEven and abundant sprayEfficient removalSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentElectrical conductorEngineering

The invention discloses a cleaning device for semiconductor base material, in particular to a device for removing pollutant from the semiconductor base material and the surface of a mask in the semiconductor process. The cleaning device comprises a working platform, a base and a movable cleaning unit, wherein the base comprises two parallel vertical base plates, each vertical base plate is provided with a bottom end and a top end, and the bottom end of each vertical base plate is arranged on the working platform; and the movable cleaning unit is pivoted at the tops of the two vertical base plates of the base. The movable cleaning unit is at least provided with a slender outlet which is used for delivering a fluid to the semiconductor base material or the surface of the mask.

Owner:GUDENG PRECISION IND CO LTD

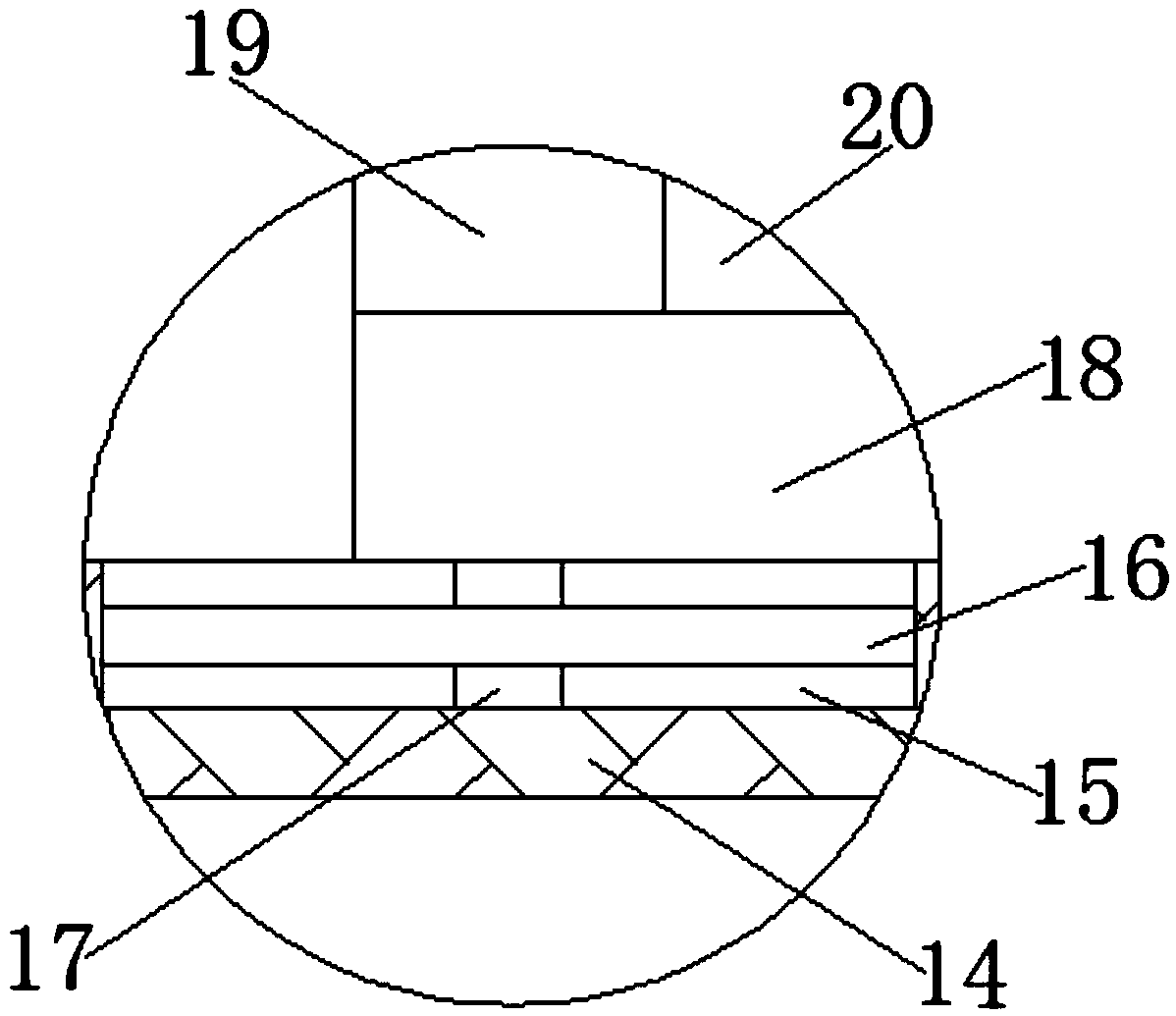

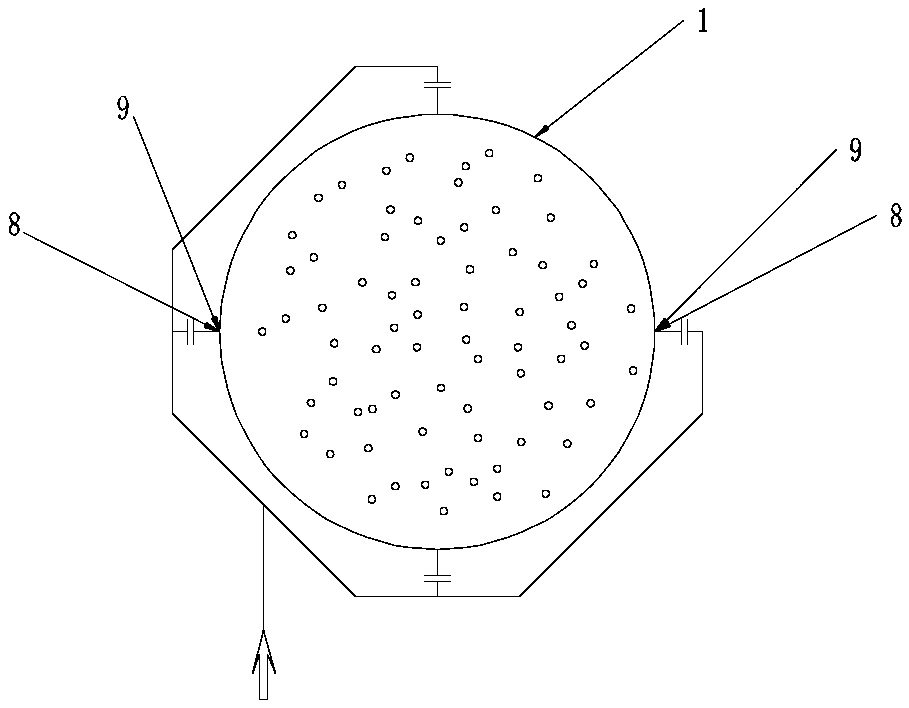

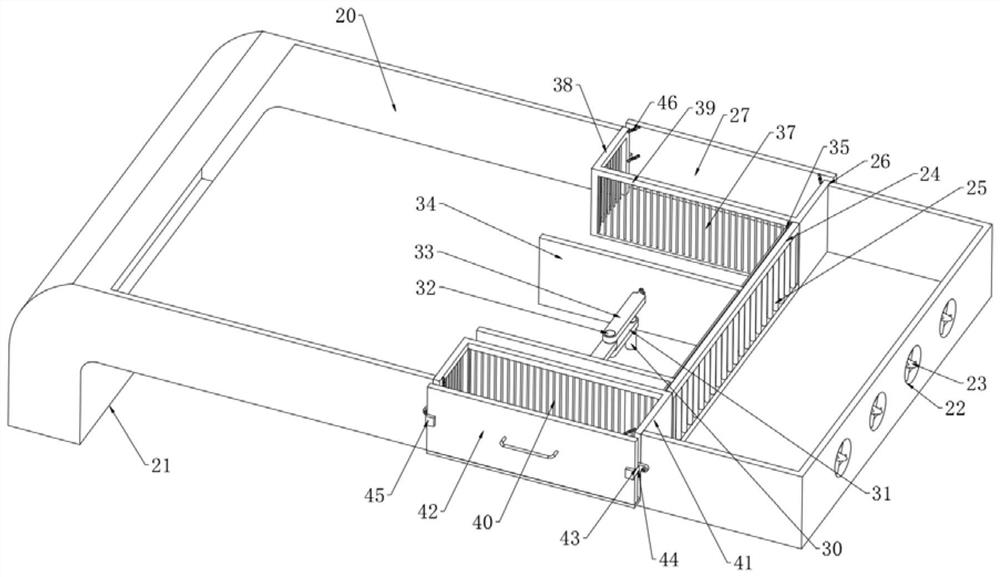

Water circulated wool cleaning device

ActiveCN108914211AImprove cleaning efficiencyAvoid readsorptionWool fibre washing/scouringWoolEngineering

The invention discloses a water circulated wool cleaning device and relates to the field of cleaning devices. The water circulated wool cleaning device comprises a base, wherein the upper surface of the base is fixedly connected with a first supporting plate, the upper surface of the base is fixedly connected with a driving device located on the left side of the first supporting plate, the upper surface of the first supporting plate is fixedly connected with a second supporting plate, and the inner wall of the second supporting plate is fixedly connected with a first ball bearing and a secondball bearing. In the water circulated wool cleaning device, fat-containing water in a first water tank enters a second water tank through a first pipeline, fat is filtered out through a filter plate,the water entering the first water tank through a third pipeline does not contain fat, and accordingly the problem is effectively solved that the existing wool cleaning device in the market makes cleaned fat still diffused in water, the fat diffused in the water is absorbed onto wool again, and accordingly a wool cleaning effect is poor.

Owner:玉环诚豪工业设计有限公司

Supercritical processing apparatus

ActiveCN111081595AAvoid damageImprove response uniformitySemiconductor/solid-state device manufacturingCleaning using liquidsStructural engineeringMechanical engineering

Owner:SEMES CO LTD

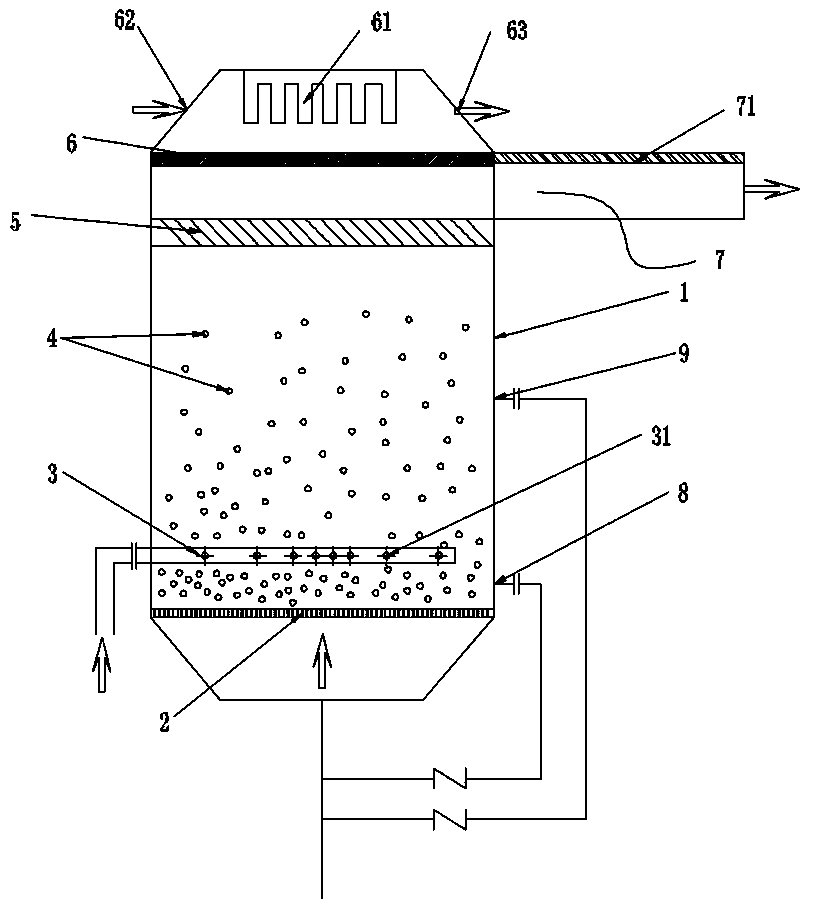

Device for drying complex solution

The invention discloses a device for drying a complex solution. The device comprises a drying bed tank body, wherein the drying bed tank body is vertically arranged, the bottom of the drying bed tankbody is provided with an air distribution plate, the air distribution plate is provided with air distribution holes, the lower portion of the drying bed tank body is horizontally provided with a material distributing pipe, the material distributing pipe is provided with spray holes, the upper portion of the drying bed tank body is provided with a carrier intercepting net, an inert carrier is placed between the carrier intercepting net and the air distribution plate, the top of the drying bed tank body is provided with a water-steam separating plate, and a material delivery pipe is arranged onthe side face of the portion, between the water-steam separating plate and the carrier intercepting net, of the tank body. The device utilizes moving collision of the inert carrier to prevent the spray holes from being blocked by formed scale, is provided with the water-steam separating plate to separate steam, and ensures a drying effect. The device is not prone to blockage, is low in fault rateduring operation, efficient, reliable, good in drying effect and easy to maintain.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

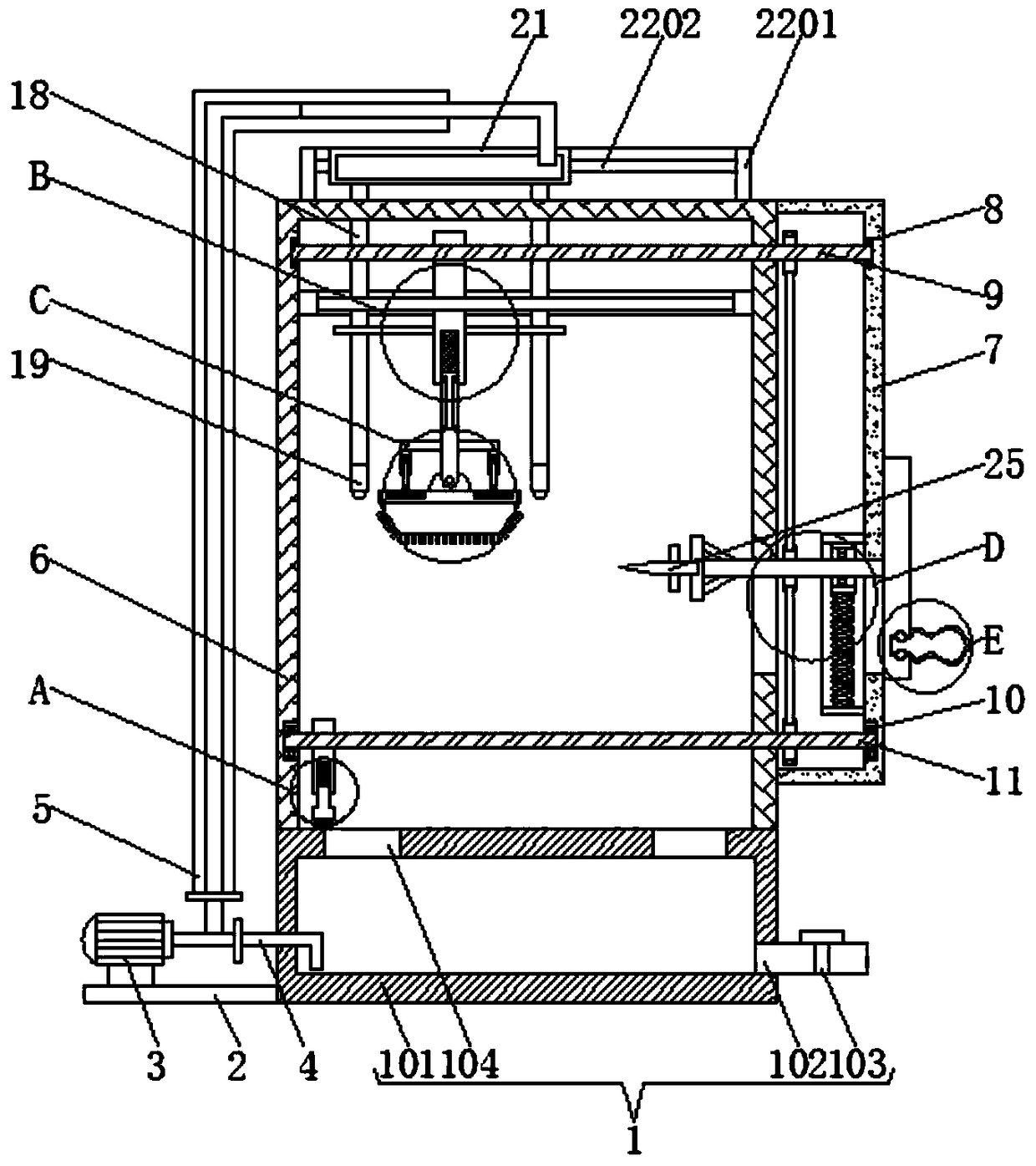

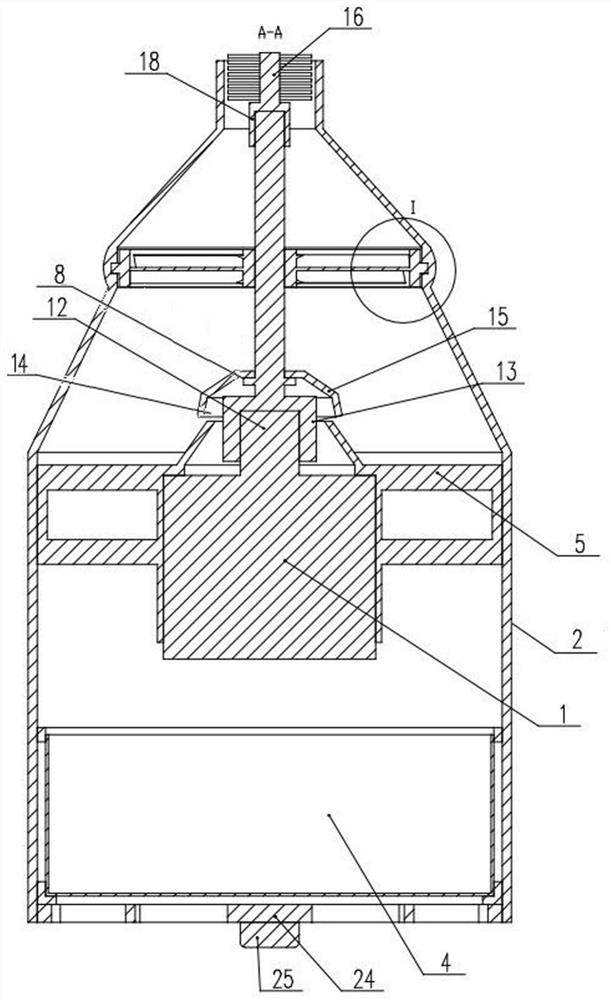

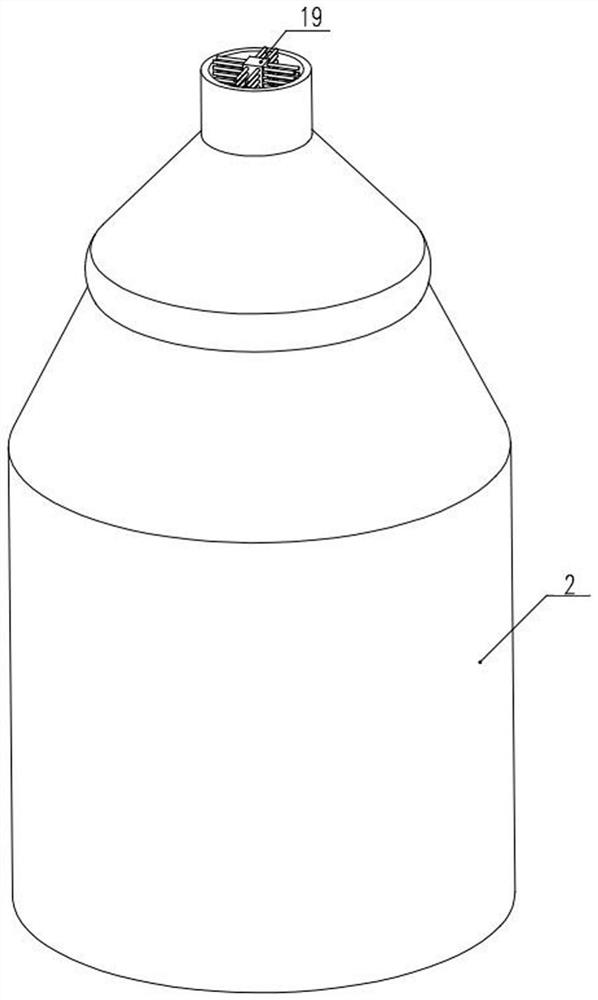

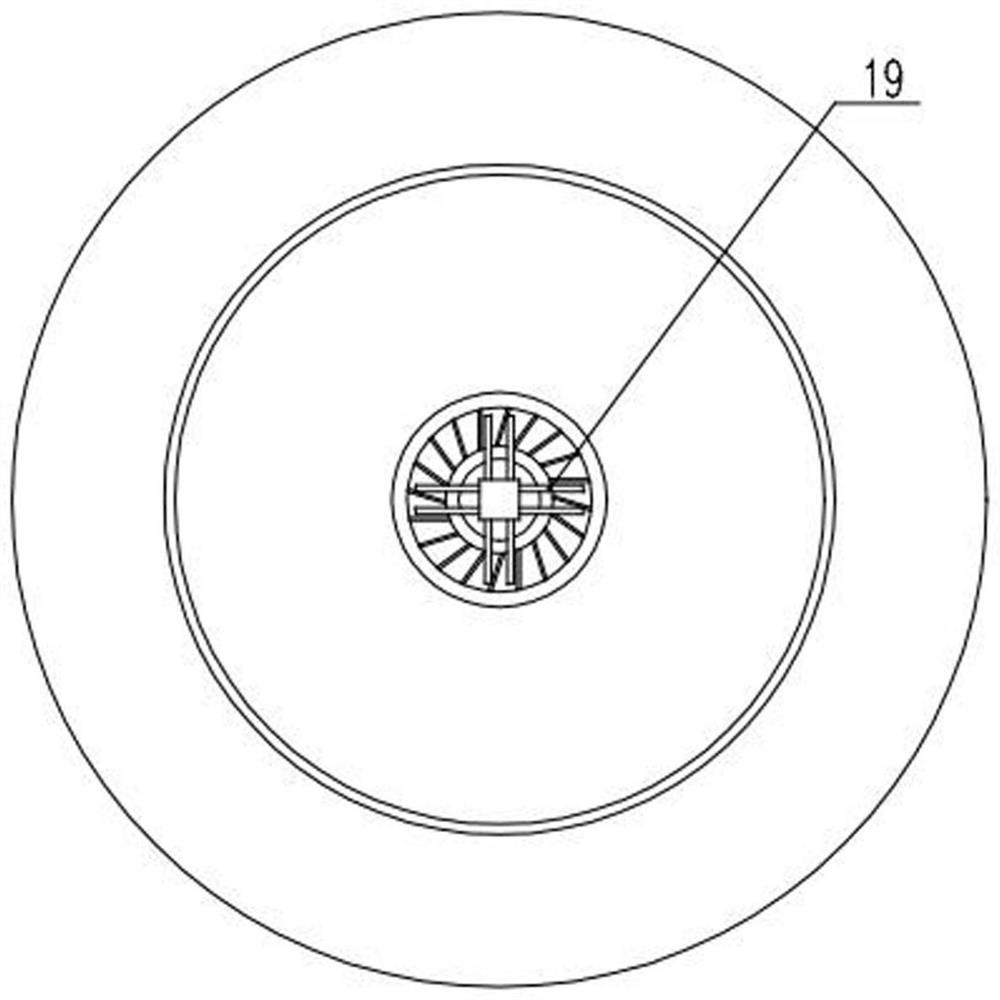

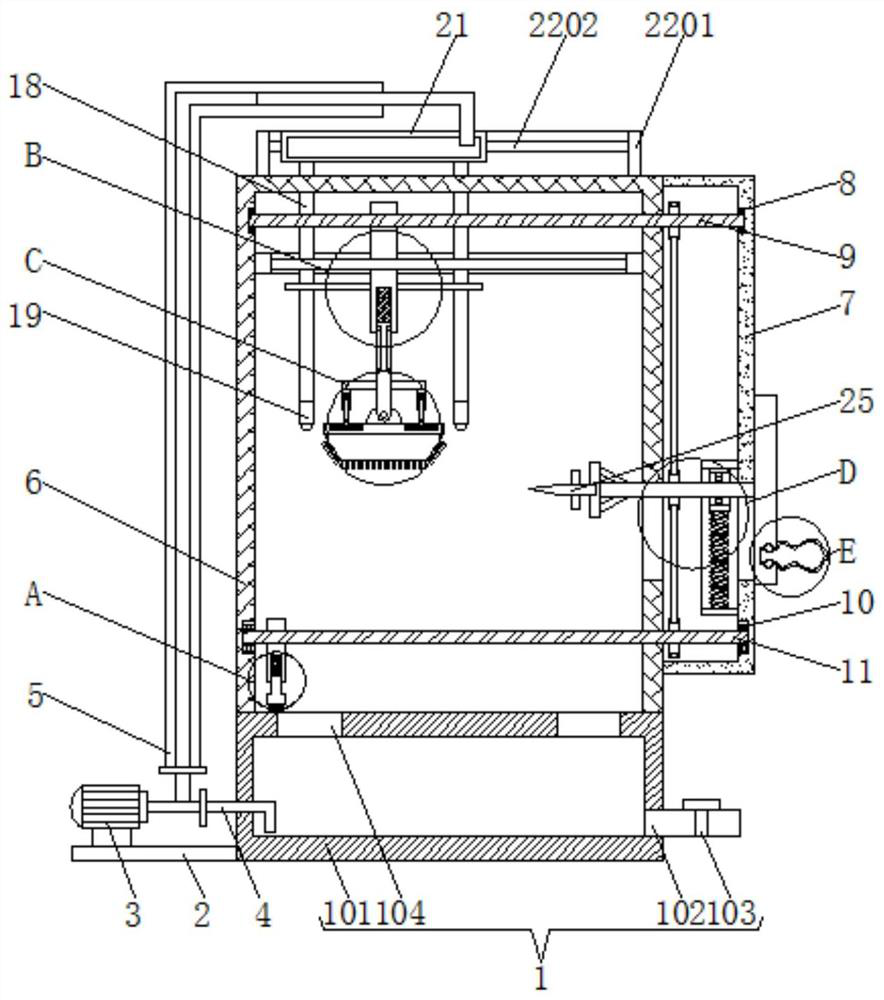

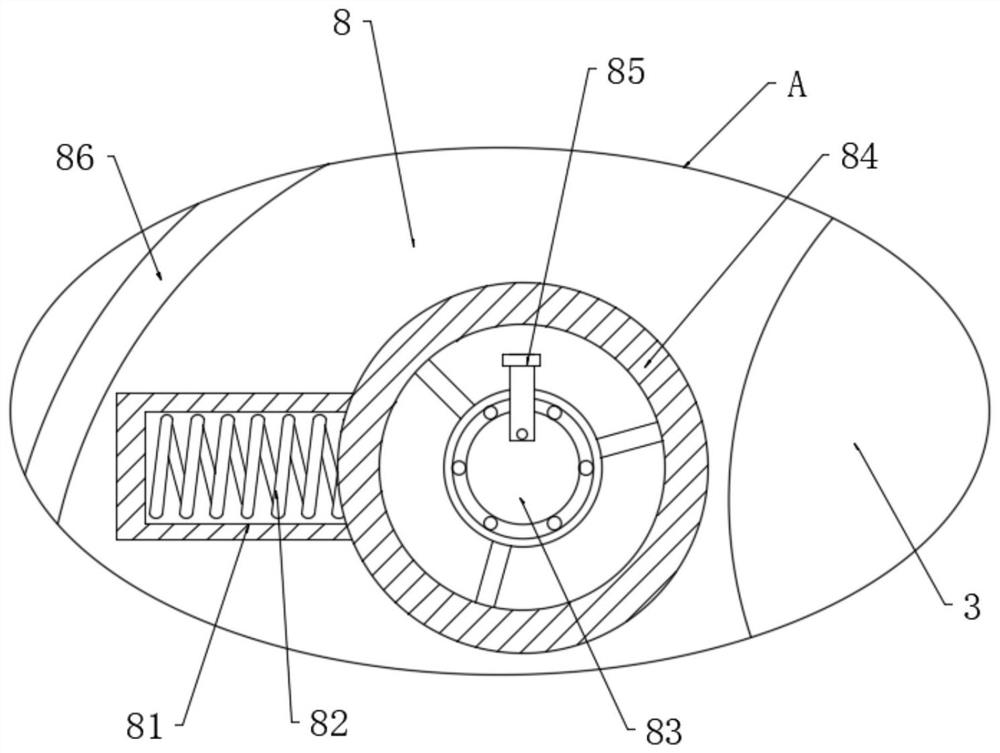

Cleaning device for interior of distribution box

PendingCN113020166AAvoid readsorptionExtended service lifeDispersed particle filtrationHollow article cleaningDrive shaftElectric machinery

The invention discloses a cleaning device for the interior of a distribution box. The cleaning device comprises a main body shell with a conical upper part and a cylindrical lower part; a rack frame is fixedly arranged at the lower part of the main body shell; a motor mounting seat is arranged at the upper part of the rack frame, and a filter frame is arranged at the lower part of the rack frame; a driving device is clamped in the rack frame, and comprises a driving motor, and an output shaft of the driving motor is fixedly connected with a main transmission shaft; the top end of the main transmission shaft is fixedly connected with a rotary cleaning brush head; the middle part of the main transmission shaft is connected with an air draft impeller, and the edge of the air draft impeller is clamped on the main body shell; and a plugging rear cover is arranged on the bottom end face of the main body shell, a motor switch is arranged on the plugging rear cover, and the motor switch is electrically connected with the driving motor. The cleaning device has the advantages of being simple in structure, convenient to use, high in safety coefficient, low in cost and good in cleaning effect.

Owner:建投邢台热电有限责任公司 +1

A water circulation type wool cleaning device

ActiveCN108914211BAvoid readsorptionImprove cleaning efficiencyWool fibre washing/scouringBall bearingWater circulation

The invention discloses a water circulated wool cleaning device and relates to the field of cleaning devices. The water circulated wool cleaning device comprises a base, wherein the upper surface of the base is fixedly connected with a first supporting plate, the upper surface of the base is fixedly connected with a driving device located on the left side of the first supporting plate, the upper surface of the first supporting plate is fixedly connected with a second supporting plate, and the inner wall of the second supporting plate is fixedly connected with a first ball bearing and a secondball bearing. In the water circulated wool cleaning device, fat-containing water in a first water tank enters a second water tank through a first pipeline, fat is filtered out through a filter plate,the water entering the first water tank through a third pipeline does not contain fat, and accordingly the problem is effectively solved that the existing wool cleaning device in the market makes cleaned fat still diffused in water, the fat diffused in the water is absorbed onto wool again, and accordingly a wool cleaning effect is poor.

Owner:TAIZHOU CHENGGUO NETWORK TECH CO LTD

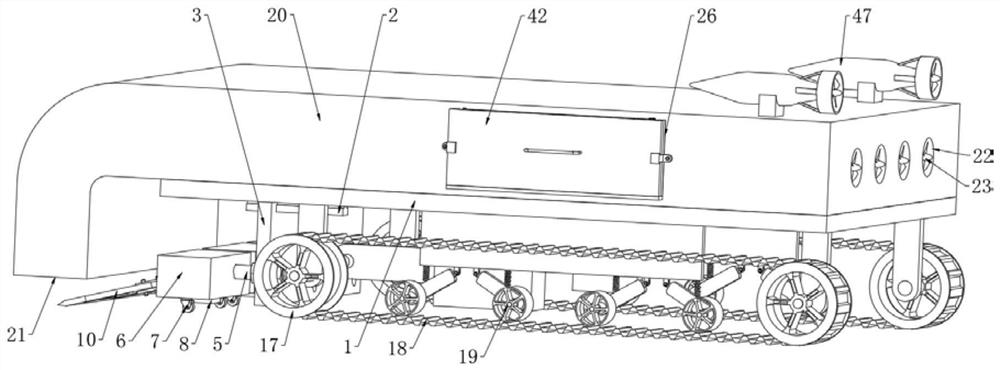

An underwater robot for cleaning the hull attachments

ActiveCN113086124BSave cleanup timeAvoid readsorptionVessel cleaningGeneral water supply conservationReciprocating motionStructural engineering

The invention provides an underwater robot for cleaning the attachments on the hull. The vertical direction of the frame is provided with several chute, one end of several push rods are respectively slidably arranged in several chute, two limit blocks are installed on the push rods, and the limit blocks are respectively located on both sides of the first push plate , and the distance between the two limit blocks is greater than the thickness of the first push plate, the front end of the first push plate is provided with several cleaning components for cleaning the hull attachments, and the several cleaning components are hinged to each other, and the push rod The other ends are respectively connected with the cleaning components, and the push rods of the cleaning components are the same in number and correspond one-to-one; the rear end of the first push plate is provided with a driving component for pushing the first push plate and the cleaning component to reciprocate. The application can clean the attachments on the surface of the ship hull underwater, which reduces the time for the ship to enter the dock for cleaning, and saves the cleaning cost.

Owner:山东金塘电子科技有限公司

Processing technology of rice good in taste and thorough in impurity removal

The invention provides a processing technology of rice good in taste and thorough in impurity removal. The processing technology comprises the following steps that dry unhusked rice is added into a gelatin composite to be evenly stirred; a mixture is cooled and fed into a rice huller for rice hull removal, and is fed into a husked rice separation machine for husked rice separation after magnetic separation; and screening grading, rice polishing, whitening, color sorting and sterilization are sequentially carried out to obtain the rice good in taste and thorough in impurity removal. The processing technology is simple, the broken rice rate is extremely low, the surface is bright and clean, impurity removal is thorough, and the taste of the rice is good.

Owner:安徽省明光市中富粮油食品贸易有限公司

Method for ultrasonic cleaning of polished sapphire substrate wafer

ActiveCN103537453BImprove oxidation capacityAvoid readsorptionCleaning using liquidsElectrolysisMetal impurities

The invention relates to a method for ultrasonic cleaning of a polished sapphire substrate wafer and provides a method for conducting cleaning through ultrasound and a solution to remove particles and metal ions and then conducting cleaning through ultrasound and oxidation liquid to remove organic matters. According to removal of the particles and the metal ions, an FA / O type chelating agent and two kinds of non-ionic surface active agents including JFC and AEO are selected and prepared to mixed liquid in proportion and the ultrasonic action is added so that cleaning can be conducted; anodic oxidation liquid obtained through electrolysis of a diamond film (BDD) is selected to remove organic pollution, the oxidation liquid is high in oxidation function, and therefore most organic matters are resolved. According to the method, comprehensive cleaning of the particles, the organic matters and metal impurities is conducted, the number of steps is small, operation is simple, and the method can satisfy the requirement of the new-period micro-electronic cleaning technology.

Owner:江西伟嘉创展企业管理有限公司

A hair removal device for cleaning peaches based on elastic extrusion and water recycling

InactiveCN108814347BSolve the problem that the peaches cannot be cleanedEasy to recycleKitchen equipmentProcess engineeringMechanical engineering

Owner:陈山

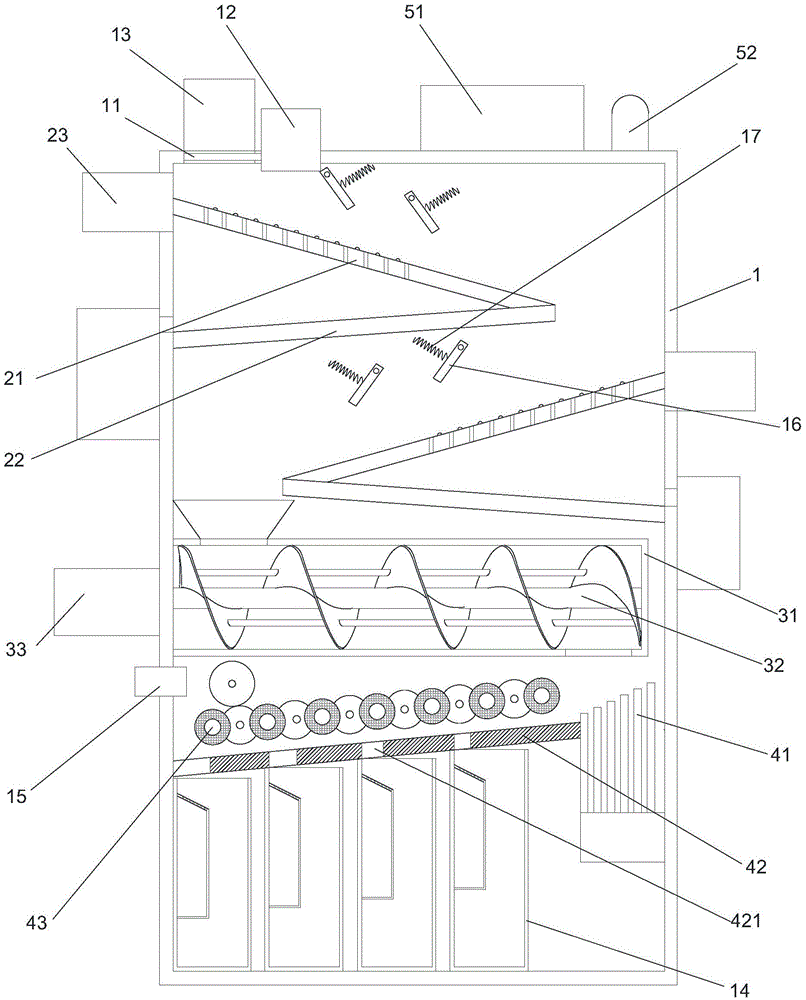

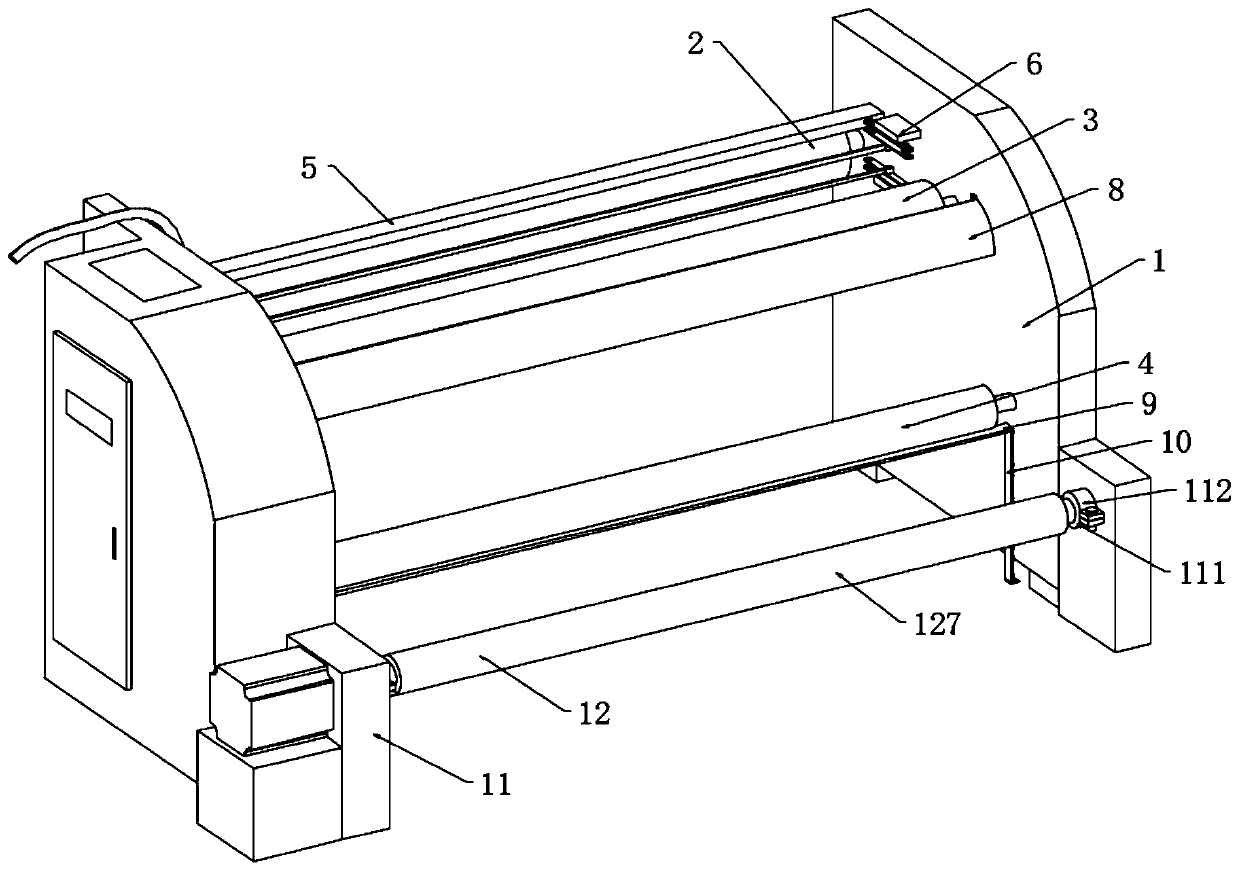

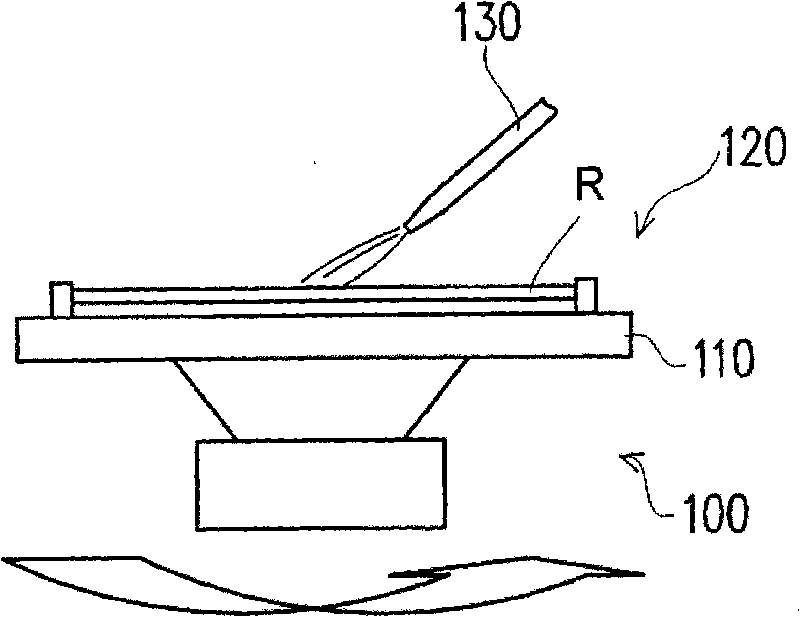

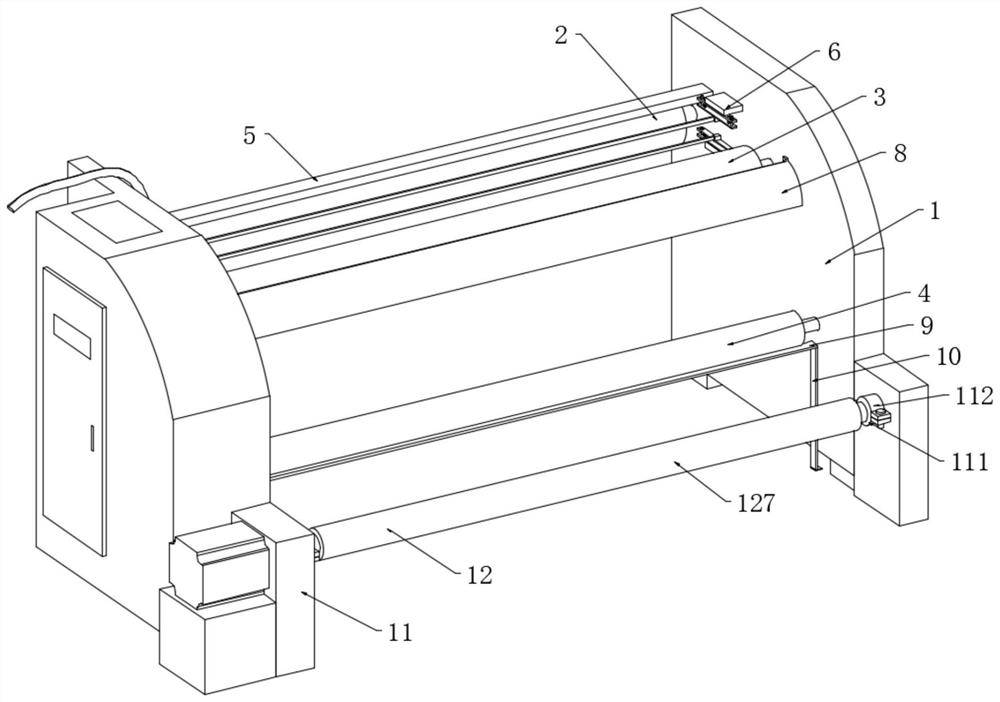

Polyimide film rolling dust removing machine

PendingCN112499327AAvoid readsorptionAvoid secondary pollutionCleaning using toolsWebs handlingDust controlEngineering

The invention discloses a polyimide film rolling dust removing machine. According to the technical scheme, the machine comprises a dust removing box, an electrostatic dust removing box, an adjusting box and a rolling box, the adjusting box is fixedly installed on the left side of the dust removing box, the rolling box is fixedly installed on the left side of the adjusting box, the rolling box comprises a third shell, a baffle is fixedly installed on one side of the third shell, a second through hole is formed in the top of the baffle, the adjusting box comprises a second outer shell, an innershell is installed on the inner wall of the second outer shell, and the left side of the inner shell is fixedly installed on the right side of the baffle. The machine has the beneficial effects that when a dust-containing polyimide film passes through the electrostatic dust removing box, the film is ionized by an electrostatic field generated by an electric field set and spray points, so that dustparticles are charged; air molecules are ionized into positive ions and electrons in a strong electric field, and the electrons encounter the dust particles when running to a positive electrode, so that the dust particles are negatively charged and adsorbed to the surface of a dust collecting grid; and surface static electricity of the polyimide film is removed through an electricity removing roller, and dust is prevented from being adsorbed again, so that the effects of removing dust and preventing secondary pollution are achieved.

Owner:JIANGYIN JUNYOU ELECTRONICS CO LTD

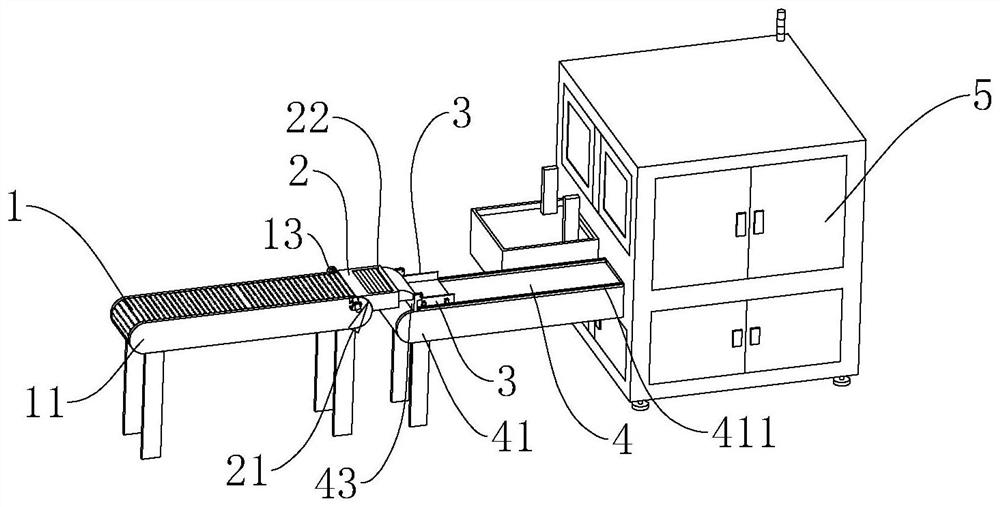

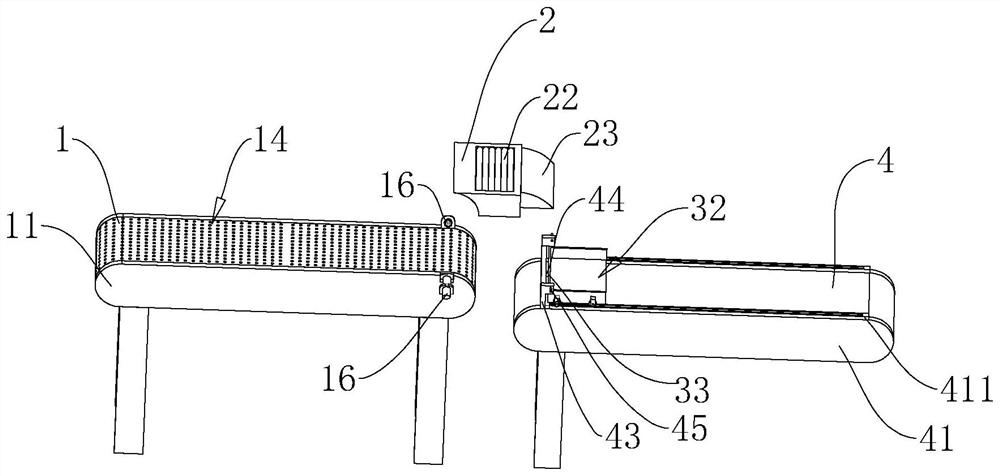

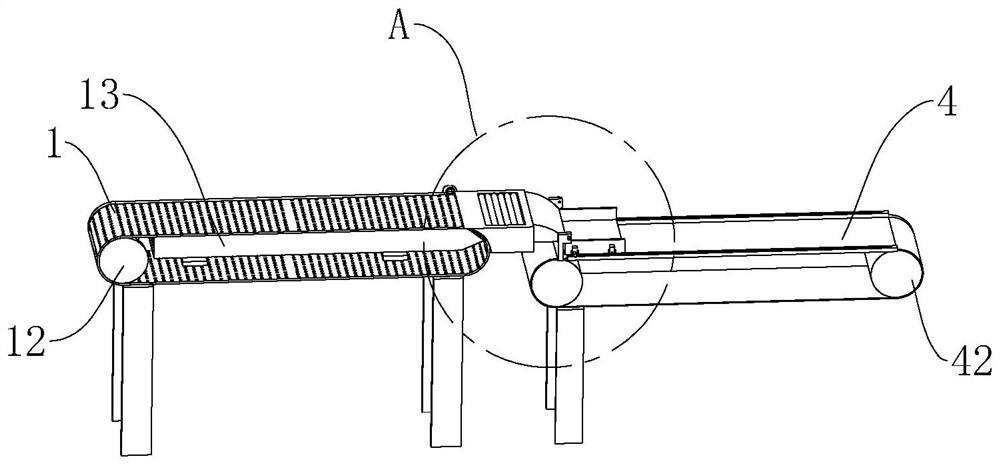

Automatic film tearing conveying mechanism and using method thereof

PendingCN114803021AAvoid readsorptionHigh degree of automationLamination ancillary operationsLaminationMechanical engineeringRelease liner

Owner:吉安嘉之宏电子有限公司

Building concrete block waste recycling device

ActiveCN114653428AImprove collection effectNo manual operationConstruction waste recoveryDirt cleaningGear wheelArchitectural engineering

The invention discloses a building concrete block waste recycling device which comprises a treatment box, a feeding hopper is arranged on the upper side wall of the treatment box in a communicating mode, a crushing mechanism is arranged in the treatment box and comprises two rotating shafts, crushing rollers are fixedly connected to the side walls of the two rotating shafts, a motor is arranged outside the treatment box, and the crushing rollers are fixedly connected to the side walls of the two rotating shafts. The two rotating shafts extend out of the treatment box and are fixedly connected with gears, and one rotating shaft is fixedly connected with an output shaft of a motor; and a collecting mechanism for collecting metal particles is arranged in the treatment box. According to the device, metal materials in the concrete blocks can be treated while the concrete blocks are crushed, manual operation is not needed, the working efficiency is improved, large metal materials can be crushed into small particles, and therefore the device can collect large blocky materials and small granular metal materials at the same time; and the collecting effect on the metal materials is better.

Owner:南通天安特种混凝土制品有限公司

Cloth surface debris treatment roller for textile machine

ActiveCN111041805BAchieve clearingAdjustable depth of contactMechanical cleaningPressure cleaningEngineeringMaterials science

The invention discloses a cloth surface debris processing roller for a textile machine, which comprises a side plate, on which a cloth feeding roller, a traction roller and a guide roller are rotatably installed, and a recovery mechanism is fixedly installed on the side plate, so that A scraping mechanism is fixedly installed on the side plate, and an ironing mechanism is installed on the side plate, a grounding rod is fixedly installed on the side plate, and a conductive sheet is fixedly connected to the grounding rod, and a pedestal, and the pedestal is connected with a collection mechanism, which is equipped with a debris scraping and recovery mechanism. When the cloth is continuously pulled for collection, the scraper is in contact with the surface of the cloth to scrape up the debris, and the recovery mechanism is in contact with the negative pressure suction. The dust device is connected, and the debris is recovered by wind force, and the scraping mechanism includes an adjustment device, so that the depth of contact between the scraper and the fabric can be adjusted, adapting to fabrics of different thicknesses, and can maximize debris removal while avoiding damage to the fabric. scrape off.

Owner:温州派瑞机械科技有限公司

Cleaning agent for heat cleaning of wellhole and preparation method thereof

InactiveCN102899009BFunctionalWith environmental protection functionDrilling compositionDemulsifierEther

The invention relates to a cleaning agent for heat cleaning of wellhole. The cleaning agent comprises the following components, by weight: 10-30 parts of Ninol, 1-10 parts of a penetrating agent JFC, 1-5 parts of a demulsifier AE8031, 10-30 parts of ethylene glycol monobutyl ether; 5-15 parts of HEDTA and 30-50 parts of water. The preparation method comprises the steps of: (1) dissolving HEDTA in water, and stirring until complete dissolving; and (2) adding ethylene glycol monobutyl ether into the solution from the step (1), stirring evenly, successively adding Ninol, penetrating agent JFC and demulsifier AE8031, and stirring evenly to obtain a finished product. The components of Ninol, penetrating agent JFC, demulsifier AE8031 and ethylene glycol monobutyl ether in the cleaning agent are all surfactants; HEDTA has descaling and scale inhibition function, so that the cleaning agent provided by the invention has the functions of surface activity, descaling and scale inhibition, and is suitable for cleaning of oil tubes in heavy oil heavy oil fields, and also has the function of environmental protection.

Owner:CNOOC ENERGY TECH & SERVICES +1

Multi-filtration standing-type honey processing method

PendingCN110679885AAvoid readsorptionHigh purityFood scienceActivated aluminaMicrocrystalline cellulose

The invention discloses a multi-filtration standing-type honey processing method. The method comprises the steps of material selection, auxiliary agent preparation, heating dispersion, multi-filtration standing, disinfection, concentration and packaging. According to the invention, a plurality of centrifugal filtration and standing modes are adopted to prevent a small amount of residual activatedaluminum oxide particles and microcrystalline cellulose particles from adsorbing fine impurities again to be enriched to form suspended particles, so that the purity of the honey is qualitatively improved through the plurality of centrifugal filtration and standing modes.

Owner:江苏润邦食品有限公司

A steel ball impurity removal classification system

ActiveCN105562351BAchieve grindingAchieve separationCleaning processes and apparatusGradingEngineeringSteel ball

The invention provides a steel ball impurity removal and classification system. The steel ball impurity removal and classification system comprises a machine box, a plurality of first impurity removal mechanisms, a second impurity removal mechanism, a ball classification mechanism and a control mechanism. A ball inlet is formed in the top of the machine box. A ball blocking door, a first driving device, a ball storage barrel and a plurality of ball storage boxes are installed on the machine box. Each first impurity removal mechanism comprises a filter plate, an impurity guiding plate and a vibration motor. The second impurity removal mechanism comprises an impurity removal box, a screw rod and a second driving device. A ball inlet and a ball outlet are formed in the impurity removal box. The ball classification mechanism comprises a plurality of dust isolation plates, a ball guiding plate, a plurality of adjusting rollers and a third driving device. The control mechanism comprises a first sensing device, a second sensing device and a control device. The first driving device, the second driving device, the third driving device, the first sensing device and the second sensing device are all in communication connection with the control device. A first time value is preset to the control device. The steel ball impurity removal and classification system is capable of simultaneously completing impurity removal and classification of steel balls, good in impurity removal effect and high in work efficiency.

Owner:芜湖文达精密机械科技有限公司

A kind of low-odor mineral reinforced polypropylene composite material and preparation method thereof

The invention discloses low-odor mineral reinforced polypropylene composite material and a preparation method thereof. The material is prepared from the following components in percentage by weight: 54-88.5% of polypropylene, 10-40% of filling minerals, 0.5-5% of an odor removing liquid, 0.2-1% of an antioxidant and 0.2-1% of a lubricant. The preparation method comprises the following steps: mixing the raw materials except the odor removing liquid in a high-speed mixer and discharging; putting the mixed raw materials into a main feeding opening of a twin-screw extruder; metering and inputting the odor removing liquid from a side feeding opening by virtue of a centrifugal pump; vacuumizing; carrying out melt extrusion and prilling by virtue of the twin-screw extruder to prepare the low-odor mineral reinforced polypropylene composite material. Compared with the prior art, the low-odor mineral reinforced polypropylene composite material prepared by the reparation method provided by the invention is excellent in mechanical property, low in VOC and environment-friendly and can be widely used in the fields of automobiles, household appliances, sports articles and the like.

Owner:上海日之升科技有限公司

Multi-station cutting device for gear processing

ActiveCN113070535BEasy to fixTake advantage ofPositioning apparatusGear-cutting machinesGear wheelMachining

The present invention relates to a multi-station cutting device for gear processing. The present invention relates to the technical field of gear processing. After the pressure seat is threaded with the fixed cylinder, as the locking assembly is continuously screwed in, the locking assembly presses down the movable support arm, at this time the movable support arm turns over around the fixed shaft and holds the gear, and then Then rotate the lower pressure seat clockwise, and clamp the gear tightly between the lower pressure seat and the movable support arm. The structure is simple and easy to fix. Gears of different thicknesses and diameters can be clamped, and the application range is wide. Save a lot of clamping time; after processing, firstly rotate the lower pressure seat counterclockwise, after the lower pressure seat is out of contact with the gear, then rotate the locking assembly counterclockwise, the locking assembly moves up, and the spring will move the movable support arm Jack up, and the gear can be removed at this time.

Owner:JIANGSU AIRSHIP GEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com