Polyimide film rolling dust removing machine

A technology of polyimide film and dust remover, which is applied to winding strips, thin material processing, cleaning methods and utensils, etc. Adhesion of dust and other problems to achieve the effect of reducing the winding gap, preventing secondary pollution, and removing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

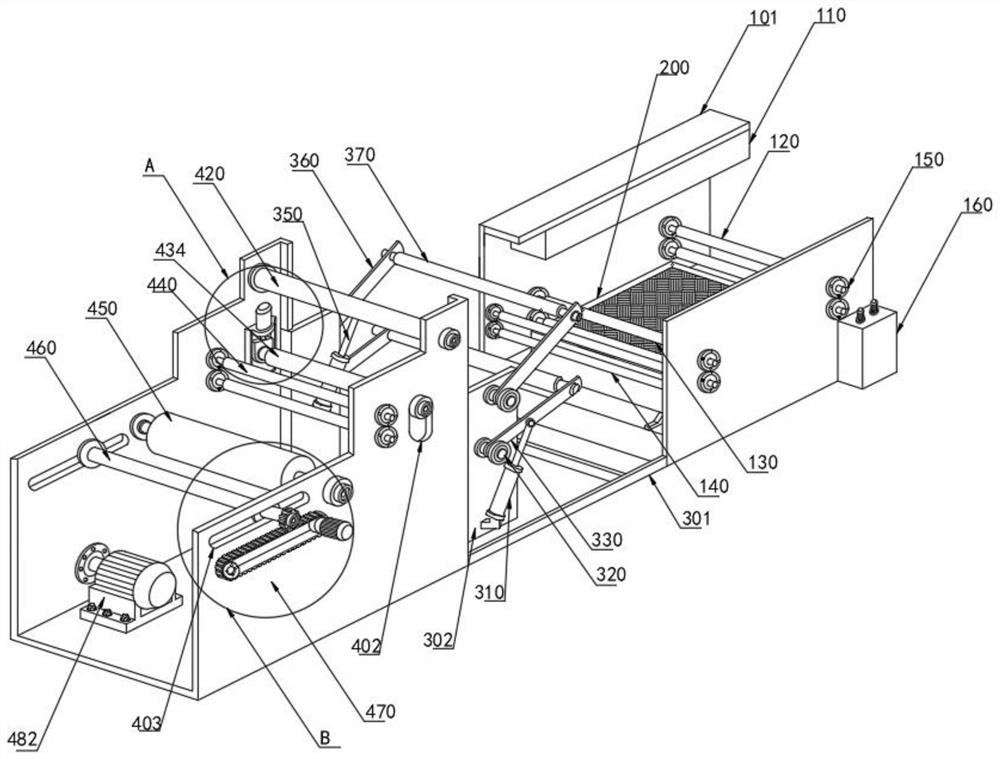

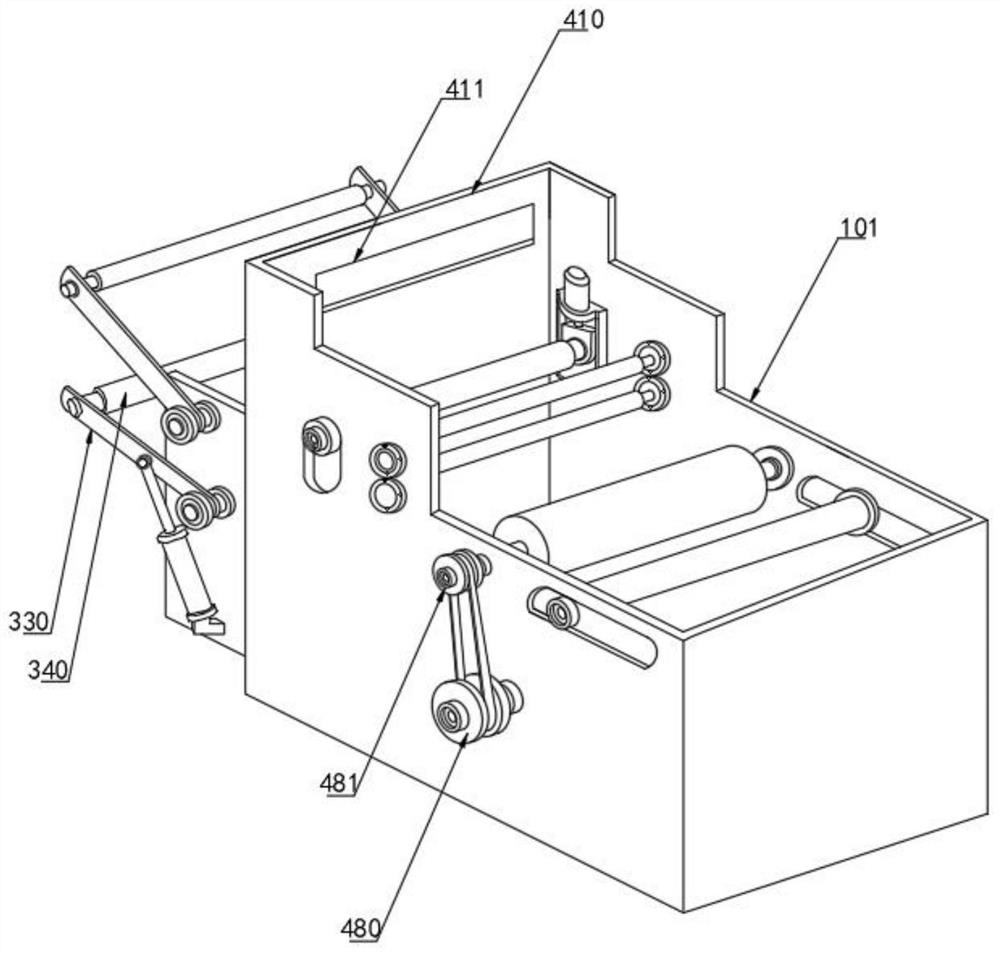

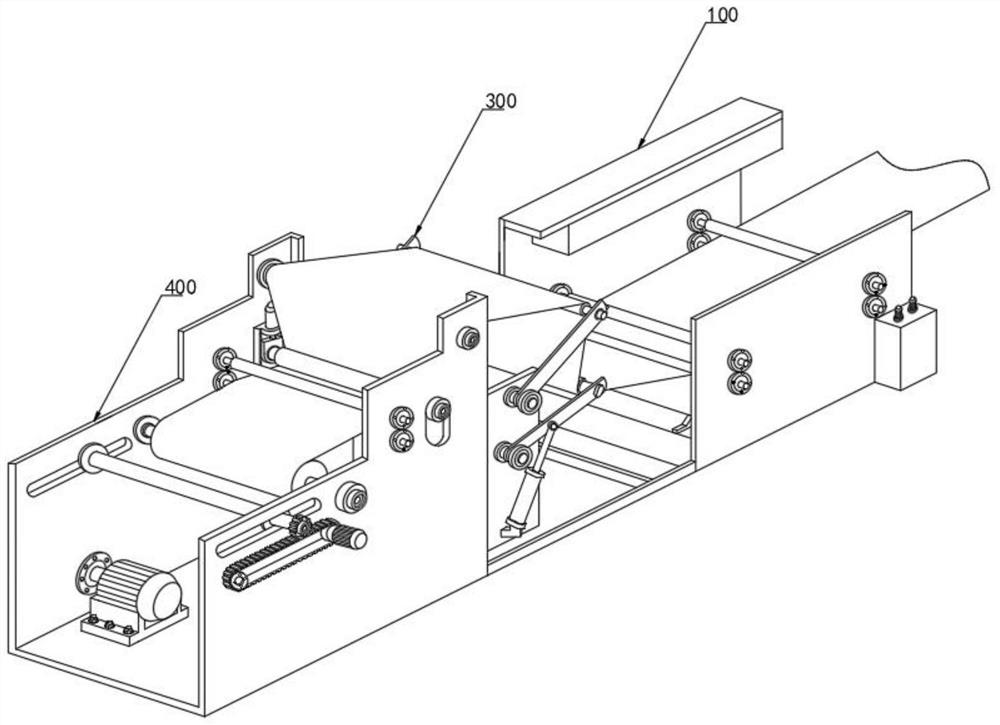

[0033] Embodiment 1, with reference to attached Figure 1-10 , a polyimide film winding and dedusting machine provided by the present invention includes a dust removal box 100, an electrostatic dust removal box 200, an adjustment box 300 and a winding box 400, specifically, the left side of the dust removal box 100 is fixedly installed with an adjustment box 300, The winding box 400 is fixedly installed on the left side of the adjustment box 300, and the winding box 400 includes a shell three 401, and a baffle plate 410 is fixedly installed on one side of the shell three 401, and the top of the baffle plate 410 is provided with a through hole two 411, and the adjustment box 300 includes a shell two 301, the inner wall of shell two 301 is provided with inner shell 302, and the left side of inner shell 302 is fixedly installed on the right side of baffle plate 410, and dust removal box 100 has the effect of dust removal to polyimide film, and adjustment box 300 has the function t...

Embodiment 2

[0045] Refer to the attached Figure 11 , a kind of polyimide film winding dedusting machine of this embodiment, also comprises sticky dust plate 490;

[0046] Further, the left side of the roller shaft four 434 is provided with a sticky board 490, and both sides of the sticky board 490 are fixedly installed on the inner wall of the shell three 401. Specifically, the surface of the sticky board 490 is coated with a unique low-viscosity glue , when the polyimide film passes through the sticky dust plate 490, the dust sticky plate 490 absorbs the dust on the surface of the polyimide film, and quickly and effectively eliminates the static electricity in the general range, and solves the dust contacted in the adjustment box 300, which has the advantages of The role of secondary dust removal.

[0047] The specific implementation scenario is: when using the present invention, workers in the field need to replace the adsorption shaft 440 with the dust sticky plate 490 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com