Gear machining multi-station cutting device

A cutting device and multi-station technology, applied in the field of gear processing, can solve the problems of metal filings sticking to the gear, slow processing efficiency, waste of working time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

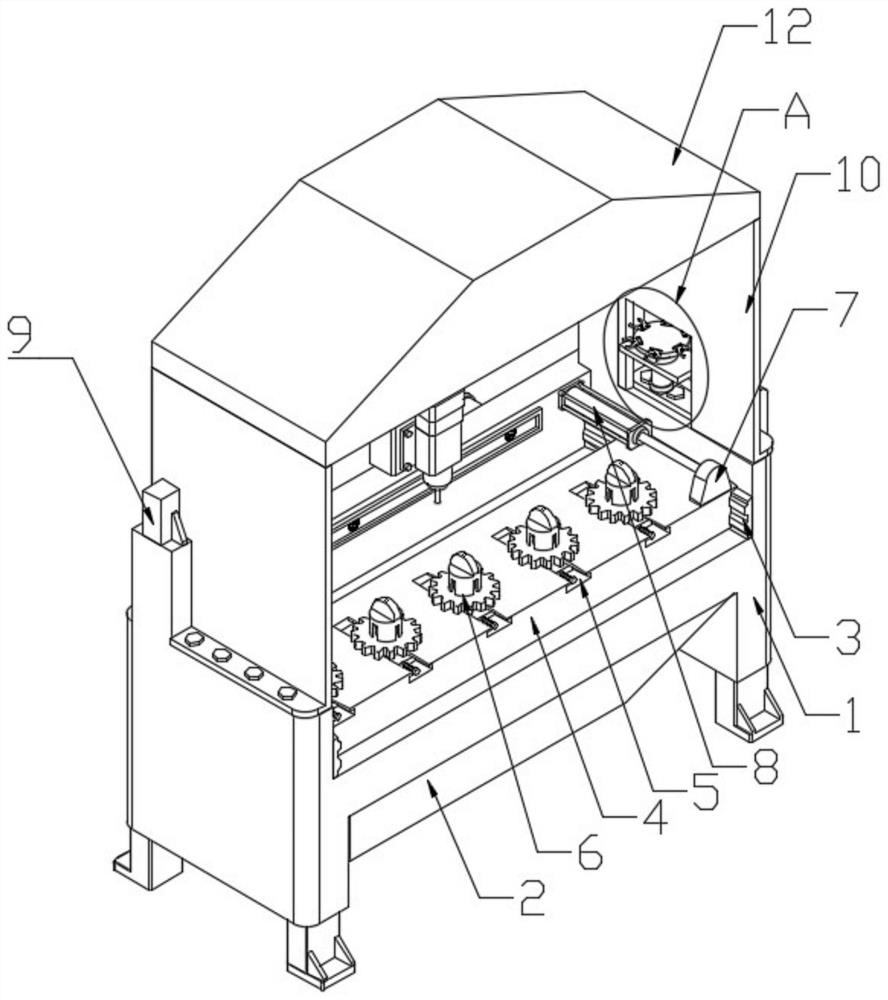

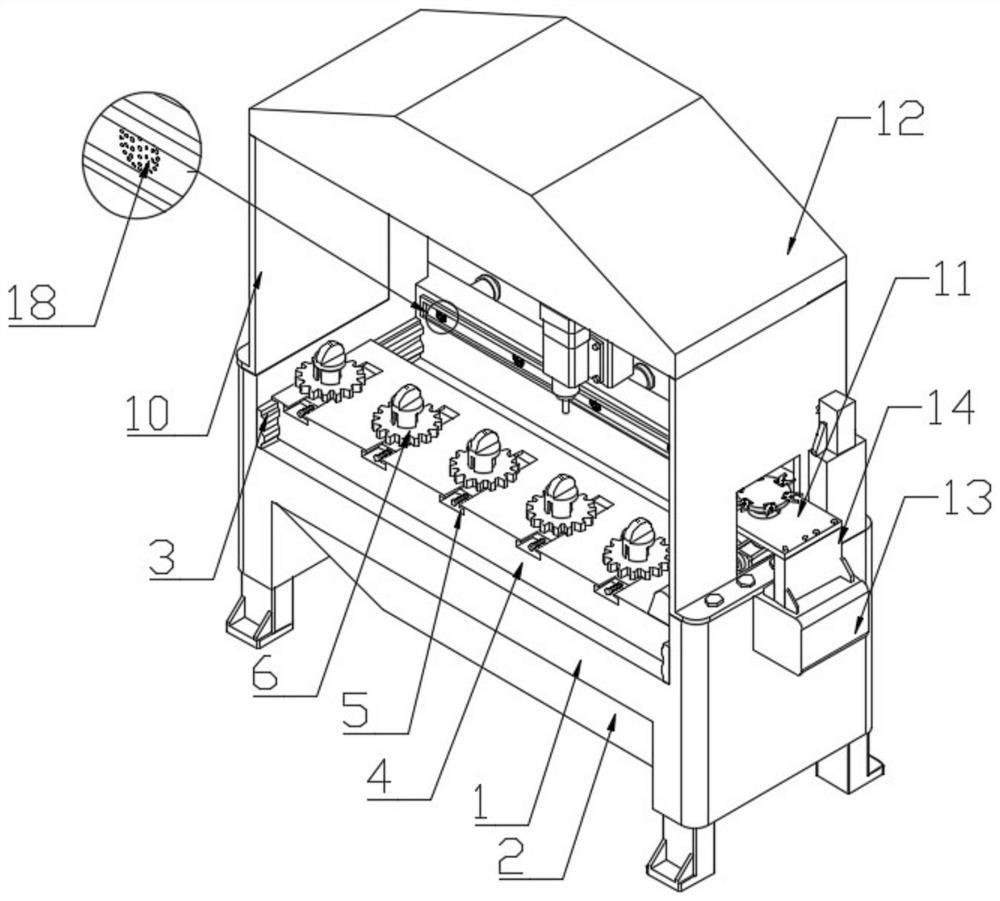

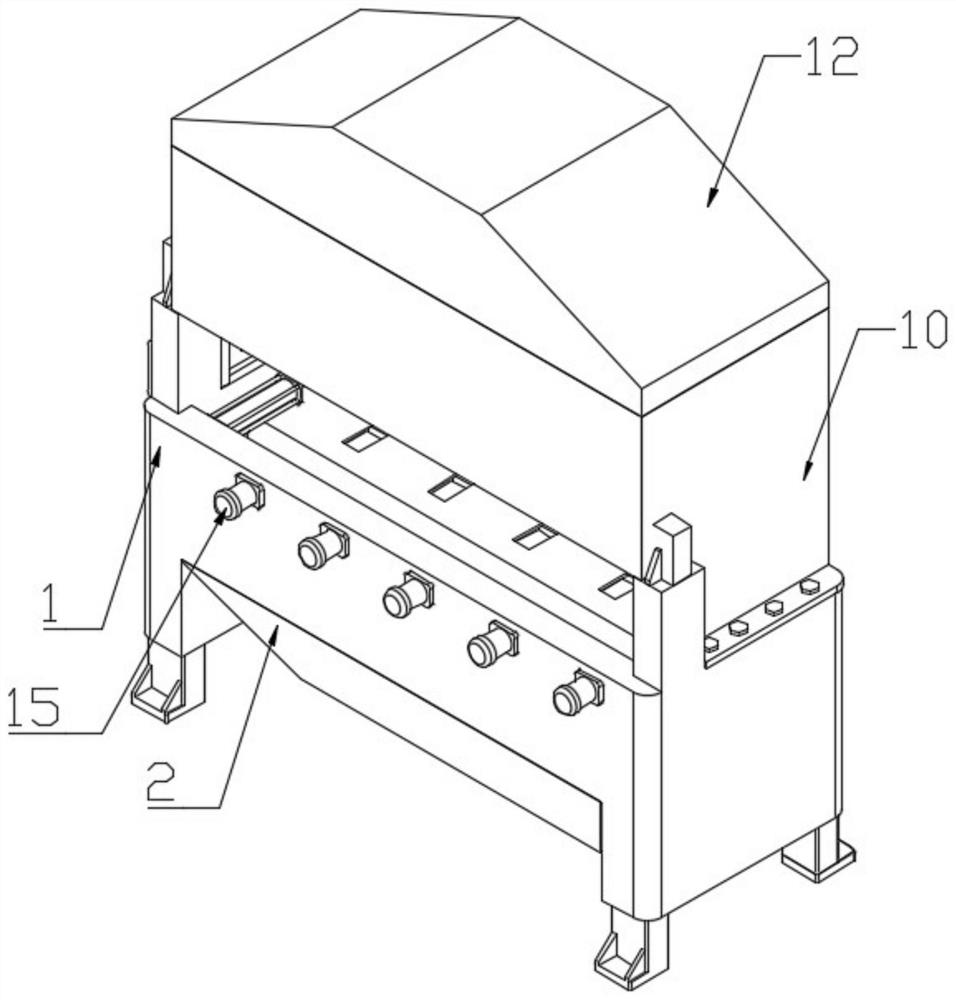

[0039] Attached below Figure 1-10 The present invention is further described with embodiment:

[0040] A multi-station cutting device for gear processing, comprising a frame body 1, a plurality of support legs are fixedly installed at the four corners of the bottom of the frame body 1, and a fixed support leg for gear processing is fixedly installed at the middle position of the bottom of the frame body 1. A scrap recycling bin 2 for scrap recycling; two slide rails 3 parallel to each other are arranged on the inner side of the upper end of the frame body 1; a sliding multiplexer is slidingly connected between the two slide rails 3 position clamping table 4; the sliding multi-station clamping table 4 has a plurality of grooves 5 for the installation of the gear clamping assembly 6; one side of the upper end of the sliding multi-station clamping table 4 is fixed A fixed block 7 is installed; a shrinking cylinder 8 is fixedly installed between the fixed block 7 and the rear wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com