Cleaning device for semiconductor base material

A cleaning device, semiconductor technology, applied in the direction of liquid cleaning method, semiconductor/solid-state device manufacturing, cleaning method and utensils, etc., can solve the problems of cracked edge of mask R, unsafe, difficult adhesion of particles or pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Although the preferred embodiments of the present invention are disclosed below, they are not intended to limit the present invention. Any person familiar with the similar art can make some changes and modifications without departing from the spirit and scope of the present invention. Therefore, the present invention The scope of patent protection shall be defined by the scope of patent application attached to this specification.

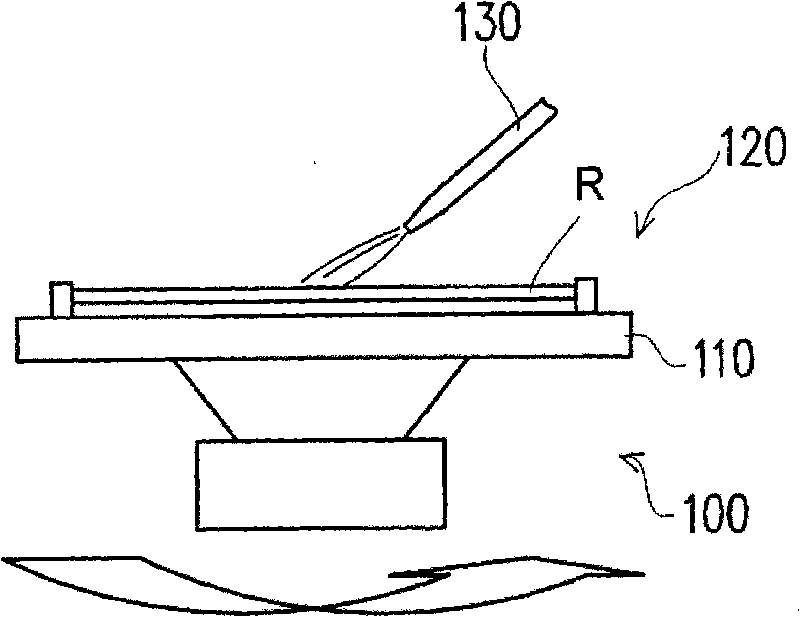

[0047] First, please refer to figure 2 , is a general view of a cleaning device of the present invention.

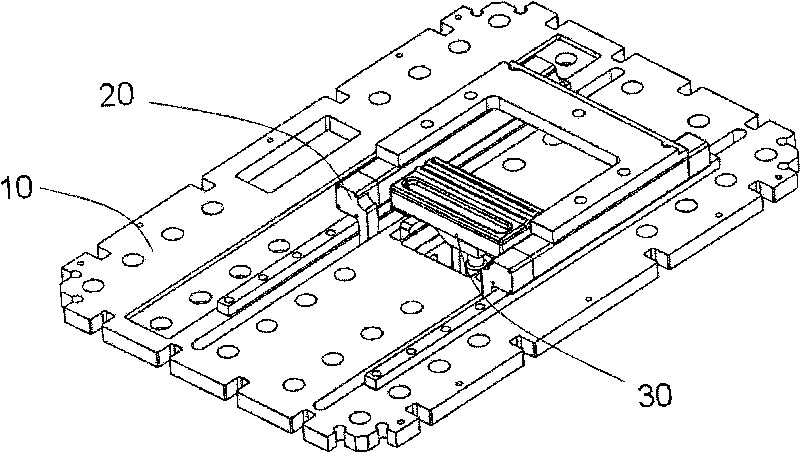

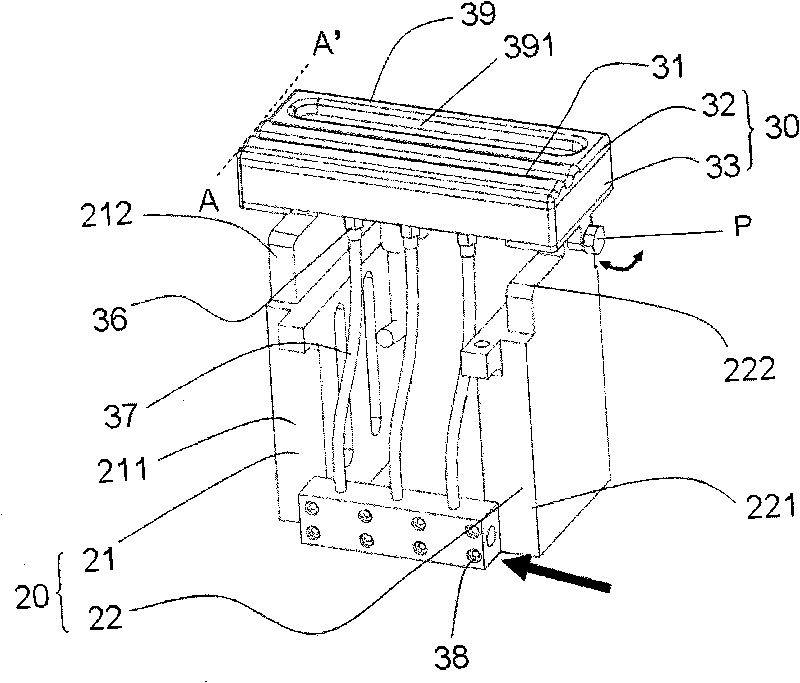

[0048] Next, please refer to image 3 , is a general view of the base and the movable cleaning unit of the cleaning device of the present invention. The cleaning device of the present invention is used to clean semiconductor substrates or masks. This cleaning device at least includes a working platform 10, a base 20 and a movable cleaning unit 30. The above-mentioned base 20 is composed of two mutually parallel The vertical substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com