New energy-saving cleaning technology and device of light oil rail tanker, liquefied gas tanker or ammonia tanker

A technology for liquefied gas tanks and oil tank trucks, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., and can solve problems such as failure to eliminate hidden dangers of accidents, no recovery device, long cleaning cycle, etc., to reduce labor The effect of intensity, simple method and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

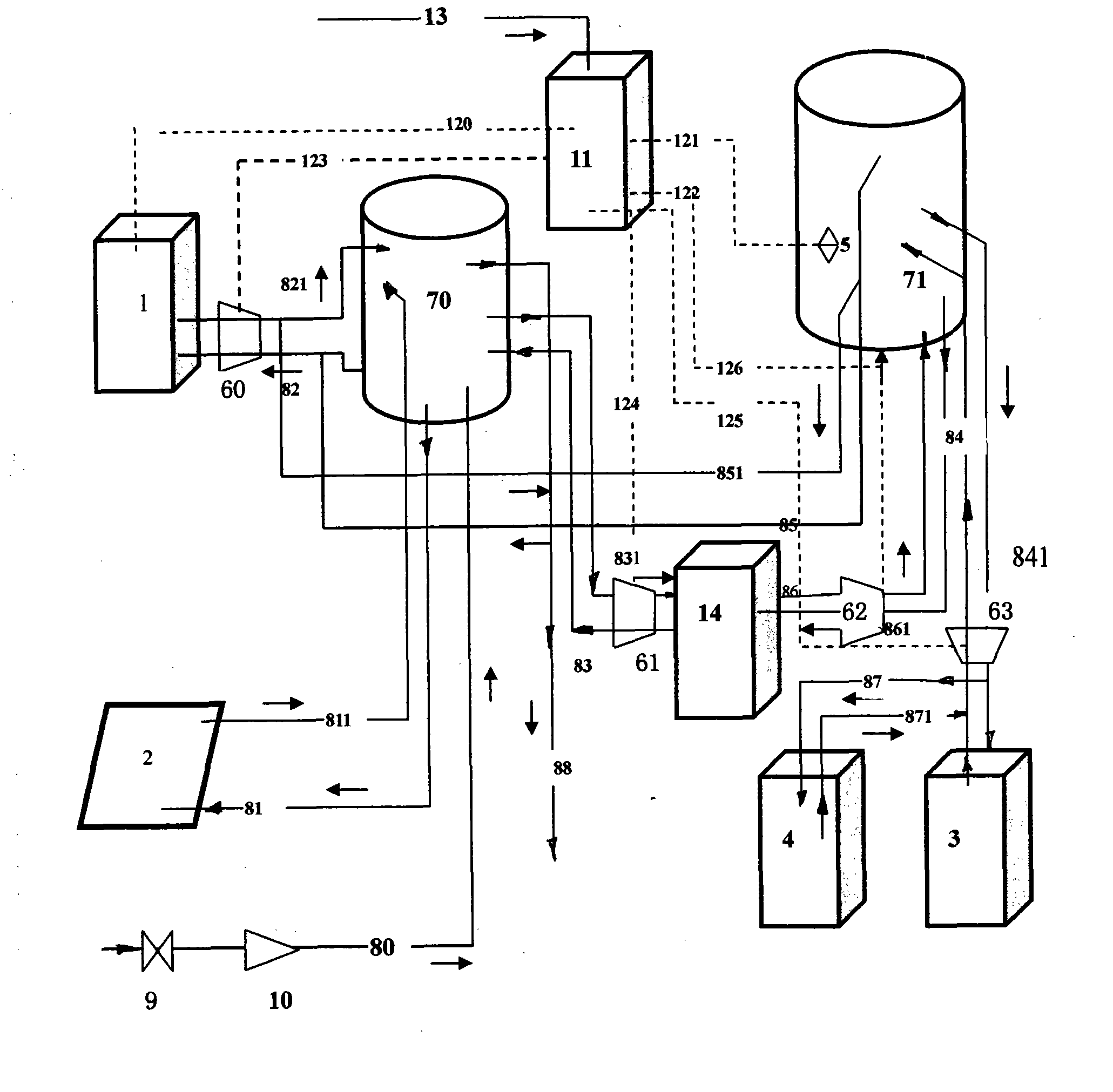

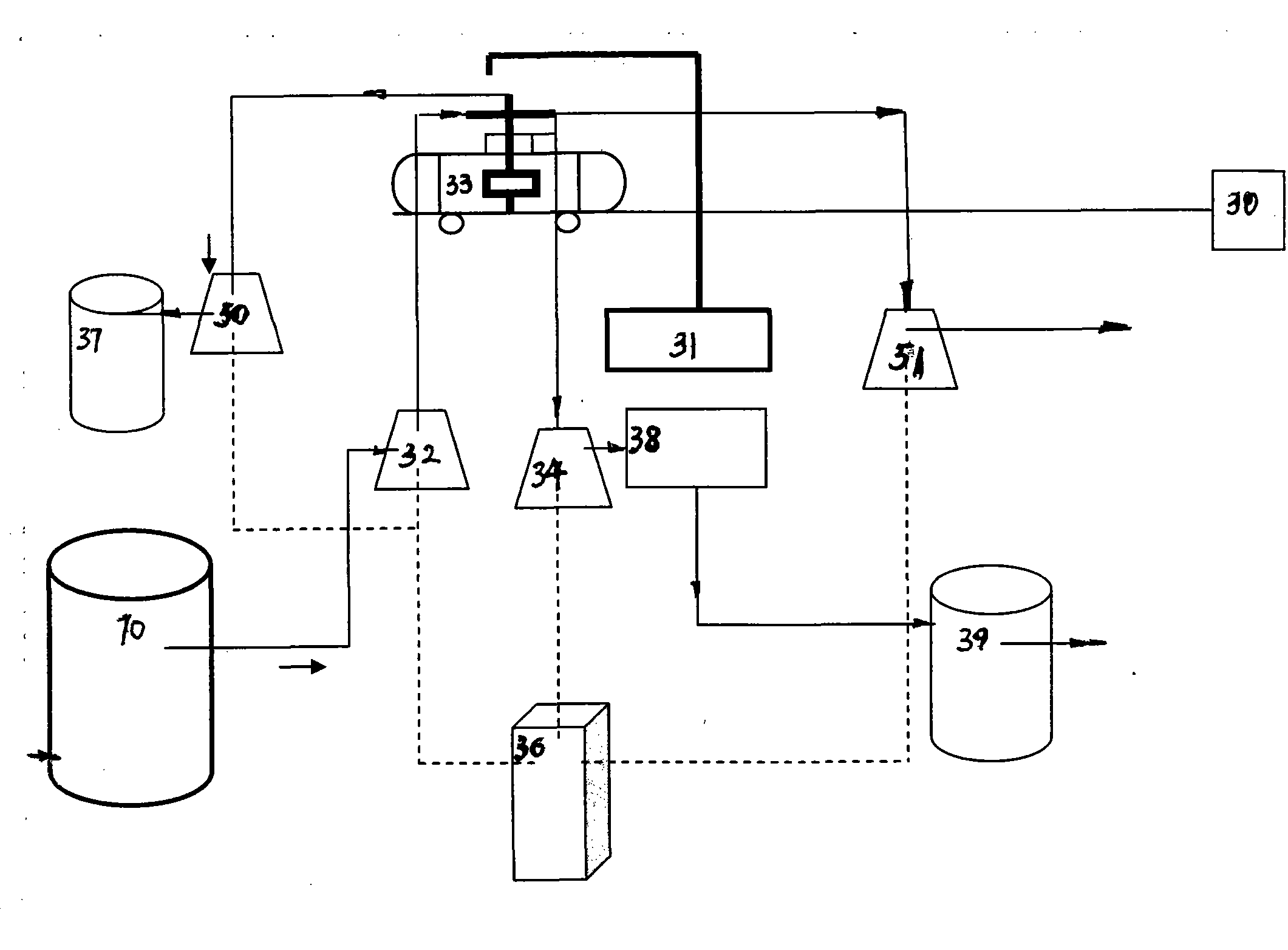

[0036] Embodiment 1 (light oil, such as figure 2 Shown): a row of light oil tank cars ready to be cleaned is towed by the traction device 30 to the line to be washed outside the tank washing station, and the light oil tank cars are towed by the traction device 30 to the cleaning platform of the light oil tank cars , after the hoisting device 31 is aligned with the opening on the upper part of the first section of light oil tanker, the hoisting device 31 will lift the water pipe on the centrifugal pump 32, the three-dimensional tank washer 33, the suction pipe on the self-priming pump 34, the vacuum pump 50 and the vacuum pump The suction pipe on the 51 is hoisted in place at one time, connects respectively the suction pipe in the centrifugal pump 32, the suction pipe of the self-priming pump 34 and the suction pipe in the vacuum pump 50,51, and the preparatory work is just in order.

[0037] First start the control button of the control device 36 vacuum pump 50, the vacuum pu...

Embodiment 2

[0039] Embodiment 2 (liquid ammonia, such as figure 2 As shown) a line of liquid ammonia tank cars to be cleaned is towed by the traction device 30 to the line to be washed outside the tank washing station, the liquid ammonia tank cars are towed by the traction device 30 to the liquid ammonia tank car cleaning station, and the hoisting device 31 is aligned with the mouth of the liquefied gas tank car Finally, the hoisting equipment 31 lifts the water pipe on the centrifugal pump 32, the three-dimensional tank washing device 33, the suction pipe on the self-priming pump 34, and the suction pipe on the vacuum pump 50 and 51 respectively;

[0040] First start the control device 36 to synchronously clean the suction control button, first use the centrifugal pump 50 to pressurize the dilute liquid ammonia in the liquid ammonia recovery device 37, and the three-dimensional tank washer 33 can rotate and revolve, and the water pressure of the jet can be within 360°. 1.0-1.5Mpa dilute...

Embodiment 3

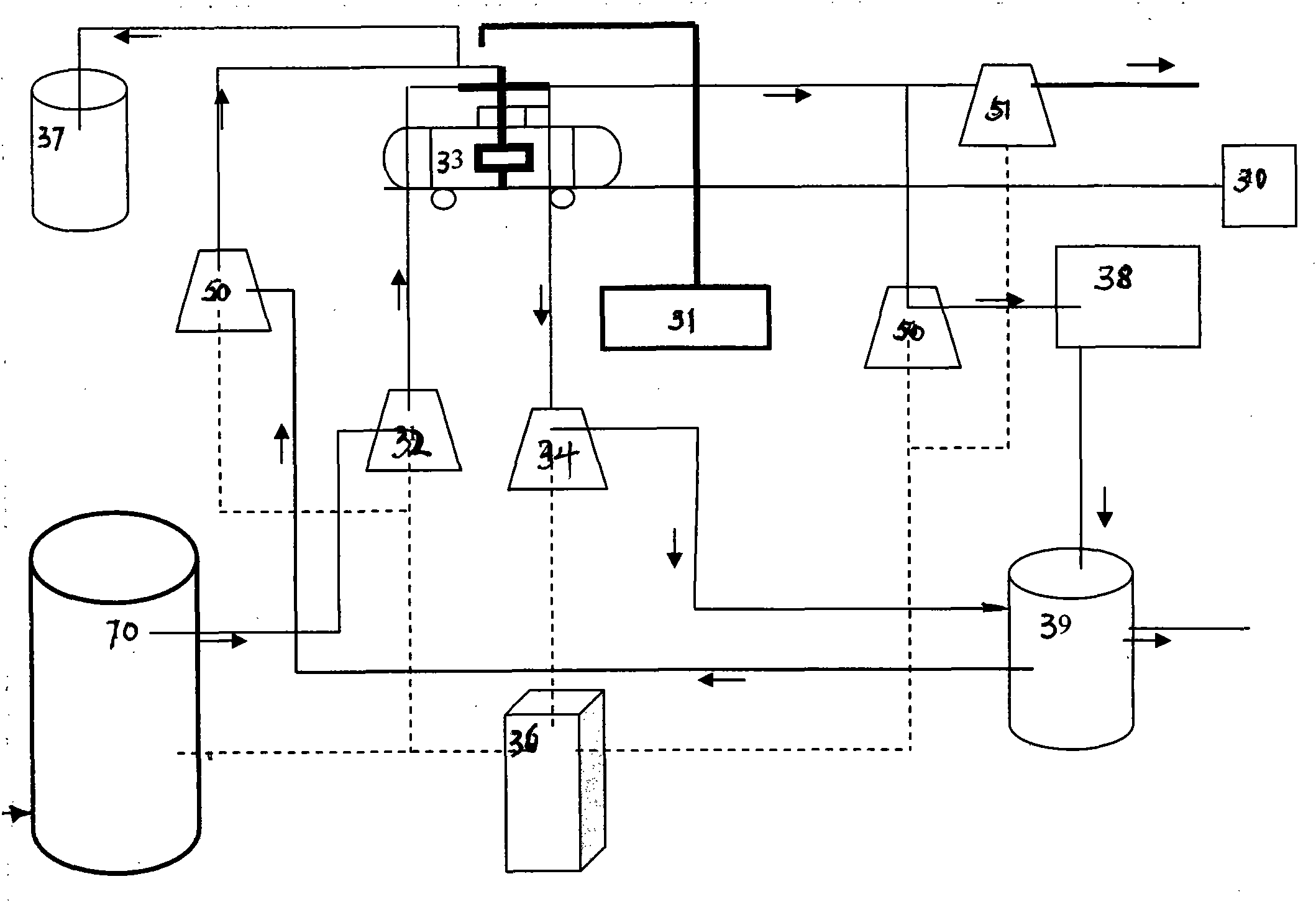

[0042] Embodiment 3 (liquefied gas, such as image 3 Shown) a row of liquefied gas tank cars to be cleaned is towed by the traction device 30 to the line to be washed outside the tank washing station of the present invention, the liquefied gas tank cars are towed by the traction device 30 to the liquefied gas tank car cleaning station, and the hoisting device 31 is aligned with the liquefied gas After the tank car entrance, hoisting equipment 31 lifts the water pipe in the centrifugal pump 32, the suction pipe in the self-priming pump 34, and the suction pipe in the vacuum pump 51 once to hoist in place.

[0043] First start the centrifugal pump 50 to suck the reclaimed water to the liquefied gas tanker, recover the residual liquefied gas through the recovery device 37 for liquefied liquefied gas, and complete the liquefied gas recovery work after 2-3 hours; then start the vacuum pump 51 suction control button , the residual liquefied gas is vacuum-sucked, the residual liquefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com