Automatic cleaning apparatus and method for money-printing rubber roll

A technology of automatic cleaning and rubber rollers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as high labor intensity, low cleaning efficiency, and physical hazards for operators, and achieve labor intensity Low cost, low cleaning cost, no harm to the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

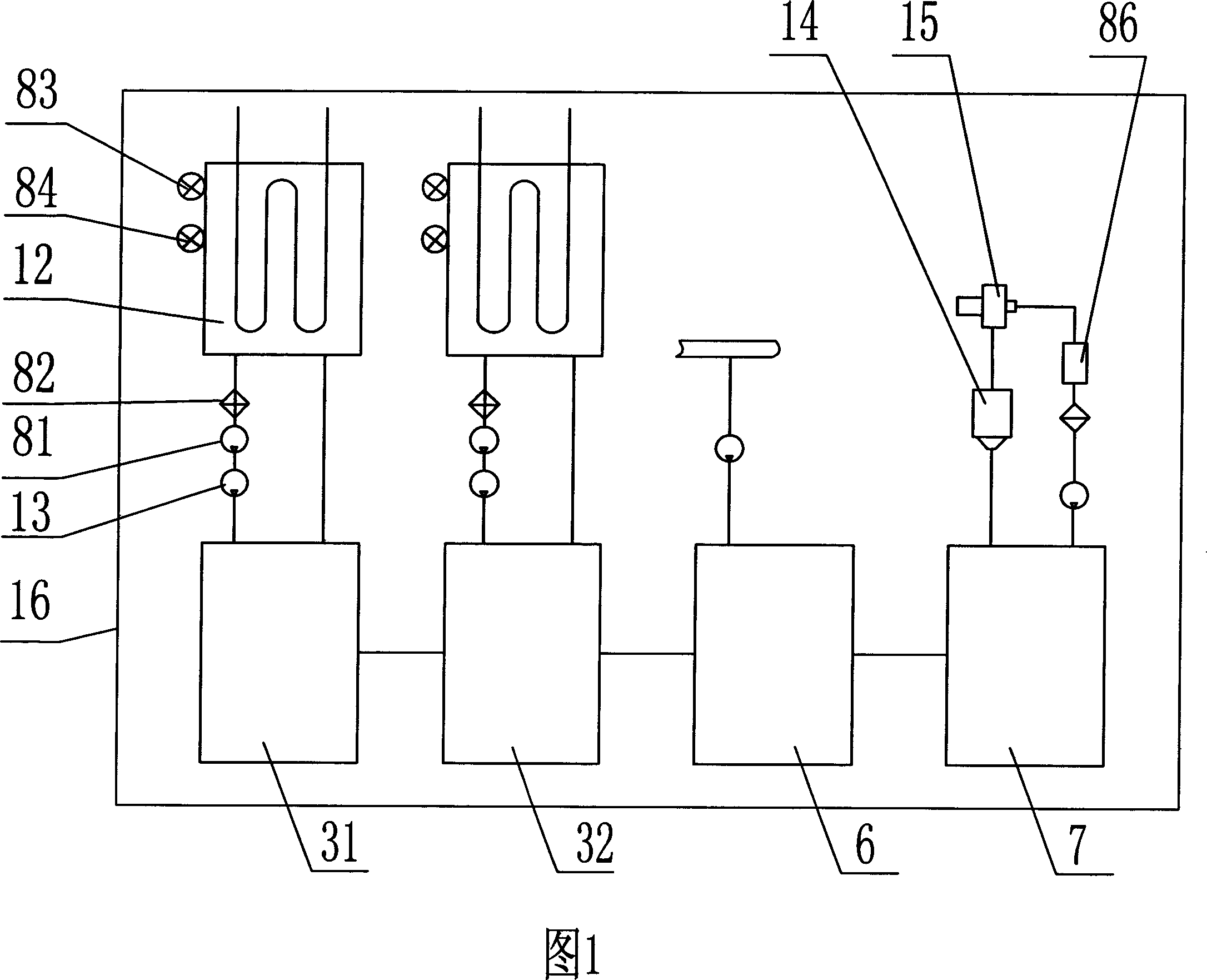

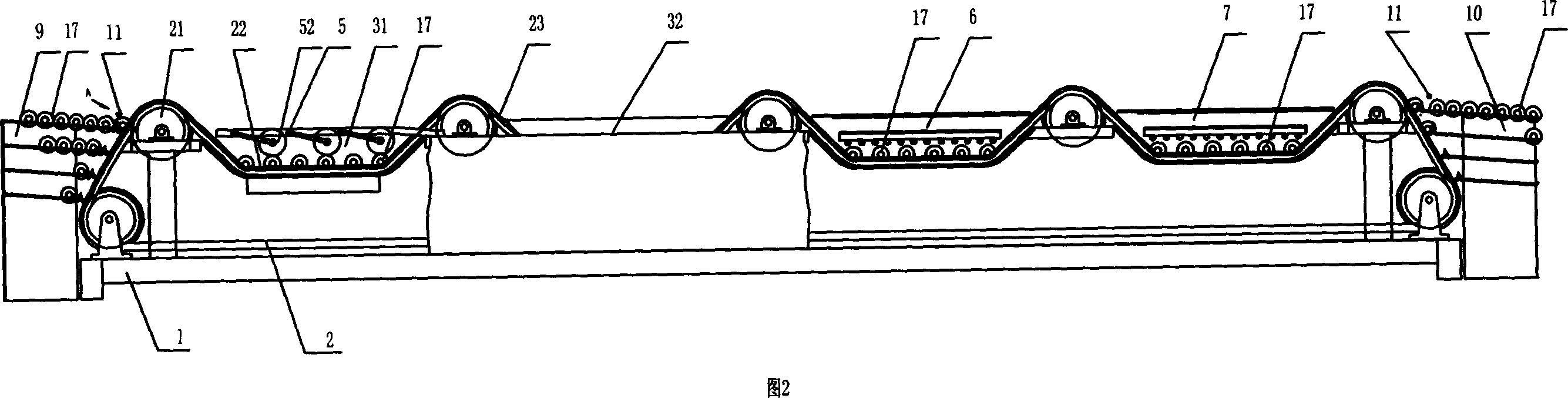

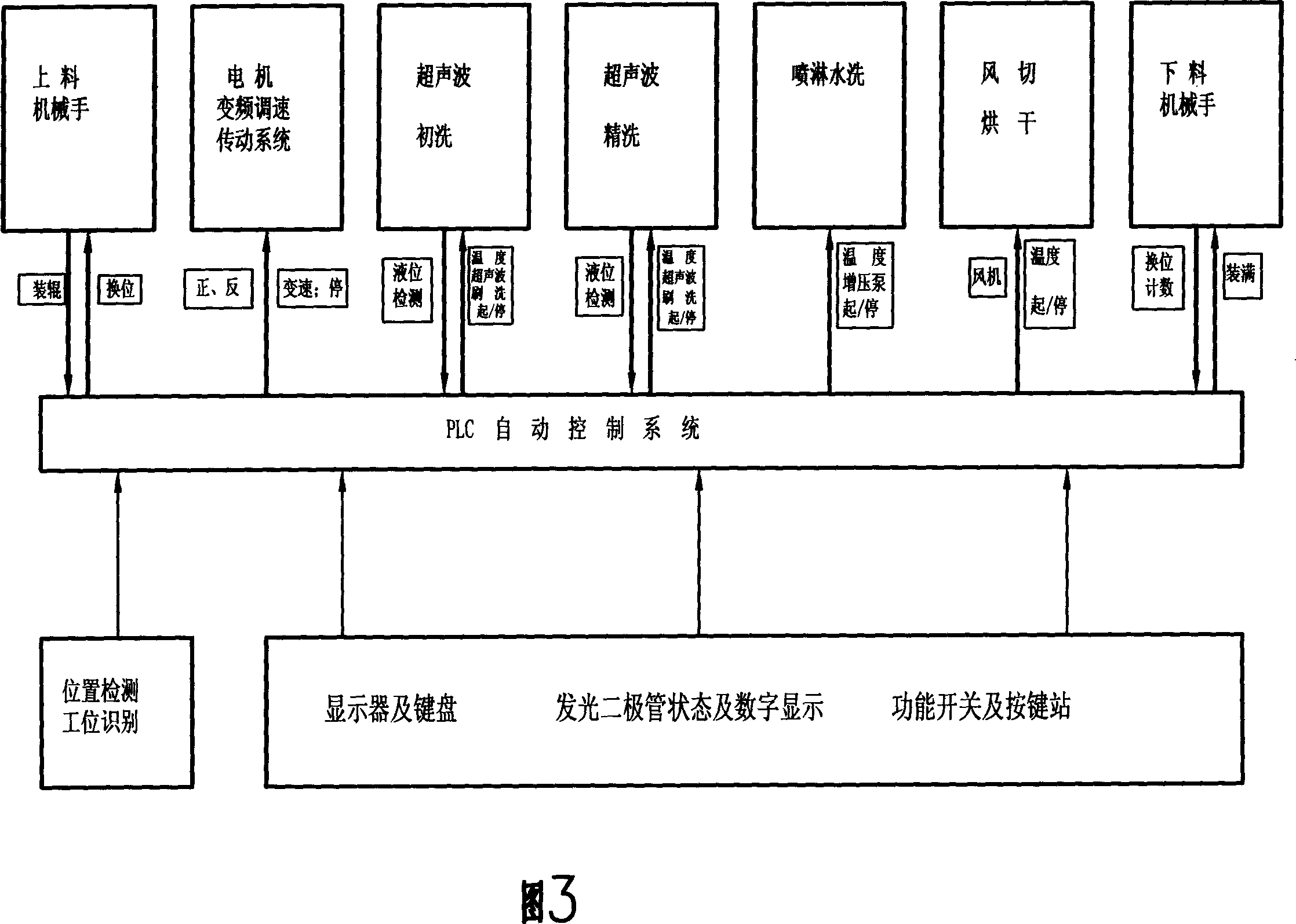

[0053] As shown in Figure 2, an automatic cleaning equipment for banknote printing rubber rollers includes a frame 1, a transmission device 2 arranged on the frame 1 and controlled by a control device, an ultrasonic cleaning tank 3, a spray tank 6 and hot air Drying tank 7, wherein, the transmission device 2 drives the rubber roller 17 to pass through the ultrasonic cleaning tank 3, the spray tank 6 and the hot air drying tank 7 in sequence, and the ultrasonic cleaning produced by the ultrasonic transducer 4 provided in the ultrasonic cleaning tank 3 Cots, spray water in the spray tank 6 to rinse the cots, and dry the cots in the hot air drying tank 7. The transmission device 2 supports and transmits the rubber roller, including a chain plate 21 installed on the frame 1, and guide rails 22 correspondingly arranged in the ultrasonic cleaning tank 3, the spray tank 6 and the hot air drying tank 7, and the chain 23 is installed on the chain disc 21 and the guide rail 22, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com